Superconduction outer rotor motor towed disc shearing device

An external rotor motor and shearing device technology, which is applied to shearing devices, cutters for shearing devices, shearing equipment, etc., can solve the problem of difficult dynamic adjustment of shearing force, complex transmission mechanism, and limited metal thick plates. Shear range and other issues, to achieve the effect of being beneficial to industrial application and solving temperature field differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

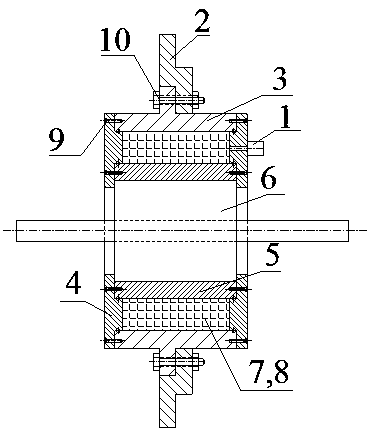

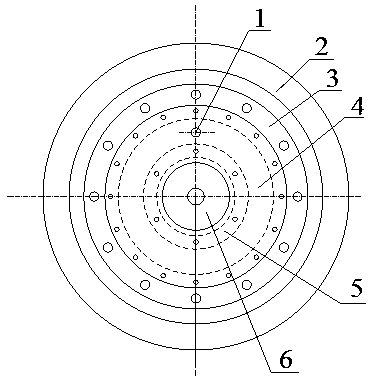

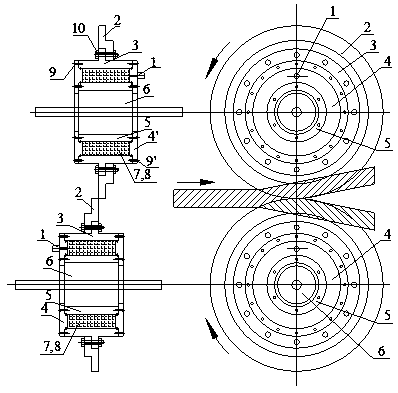

[0016] Attached below image 3 The present invention is described in detail through preferred embodiments.

[0017] Two devices of the present invention are symmetrically installed on the side of the plate strip up and down, in the annular cavity 8 formed by the outer cylinder body 3, the inner cylinder barrel 5 and the left and right annular end covers 4, 4, and loaded into the 3D printed The space bracket 7 is assembled by the left and right screw groups 9 and 9, and is evacuated by the vacuum check valve 1 to realize a heat-resistant vacuum environment. A 3D printing space support 7 is installed in the annular cavity 8 to ensure a reasonable support for shearing. A superconducting magnetic levitation structure is formed between the stator and the outer rotor of the superconducting outer rotor motor 6. By controlling the motor current, the shearing force can be realized. Control to ensure the cutting quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com