A rotary welding positioning device for lithium-ion cylindrical battery cover plate

A cylindrical battery and rotary welding technology, which is applied in welding equipment, laser welding equipment, welding/welding/cutting items, etc., can solve the problems that the focus of the laser output head is not concentrated, the motor cannot accurately position the battery, and virtual welding, etc., to improve Product welding yield, simple and reasonable structure, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

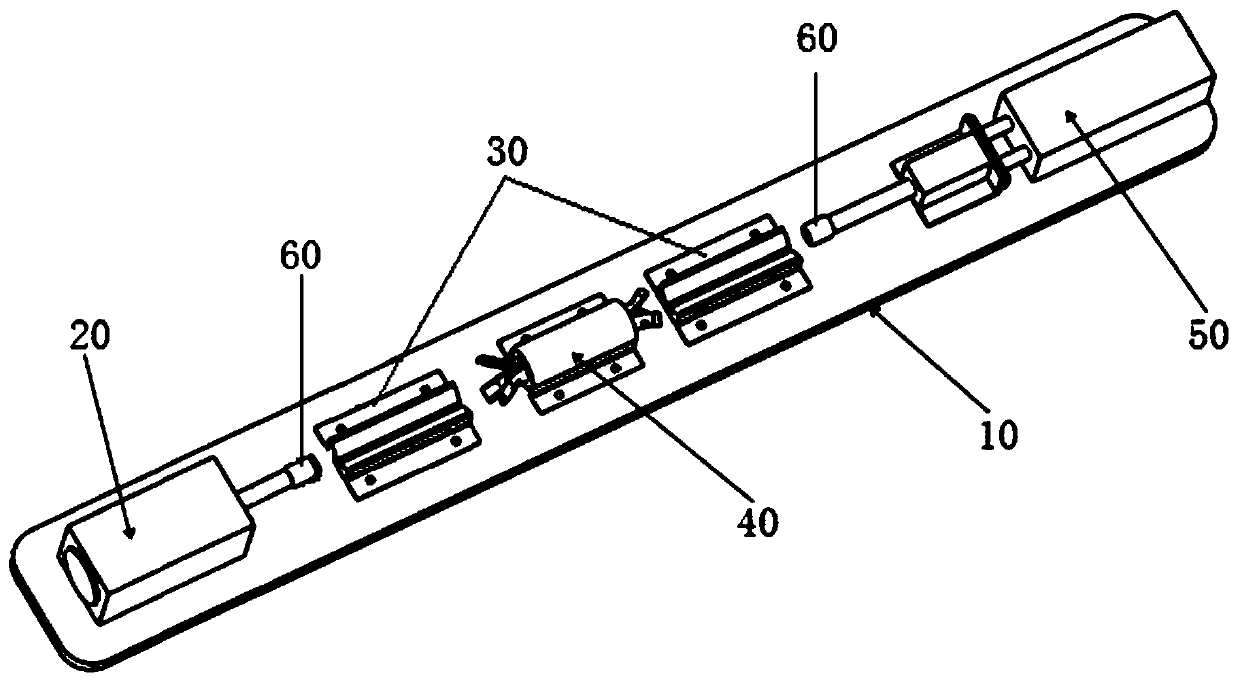

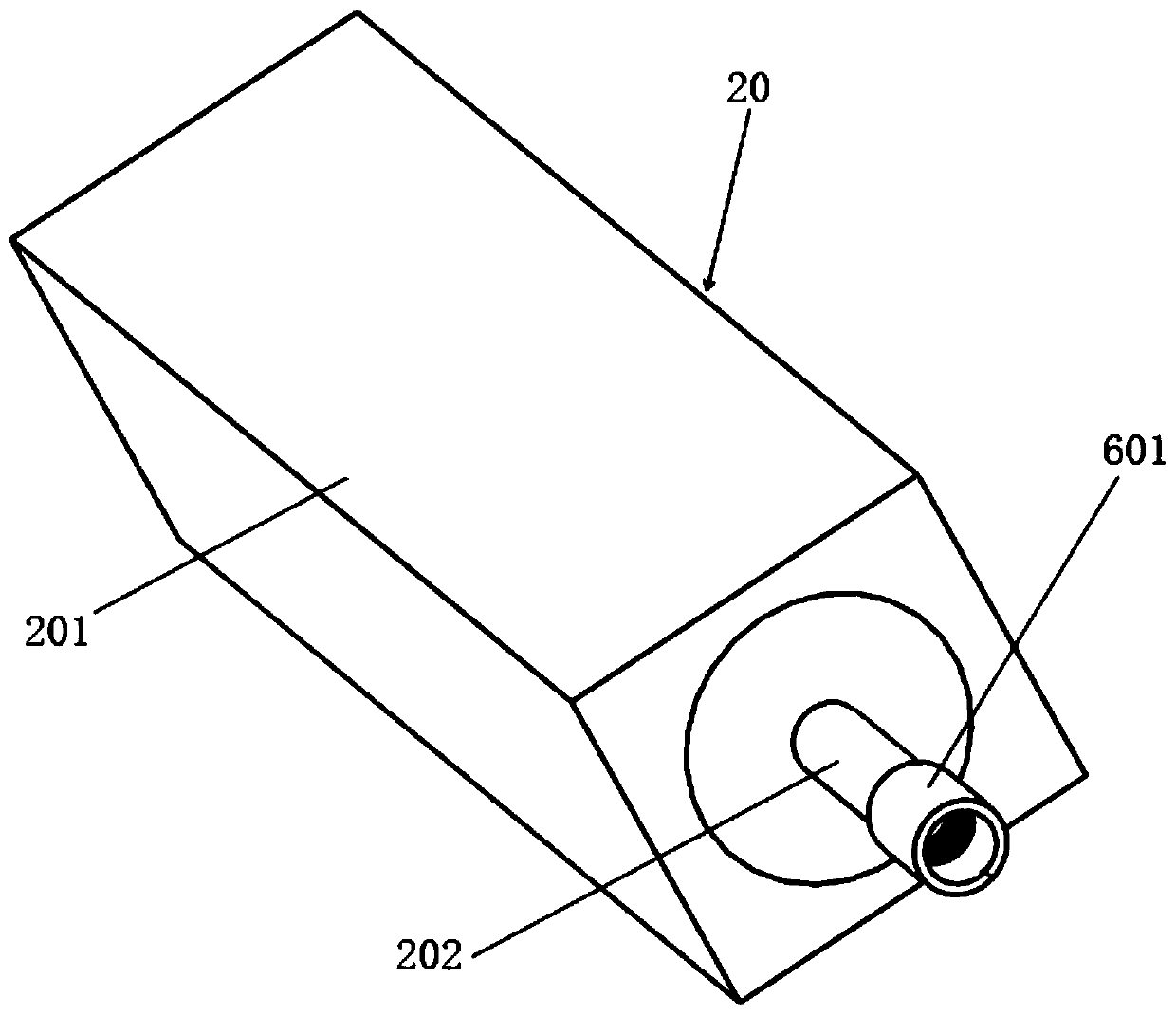

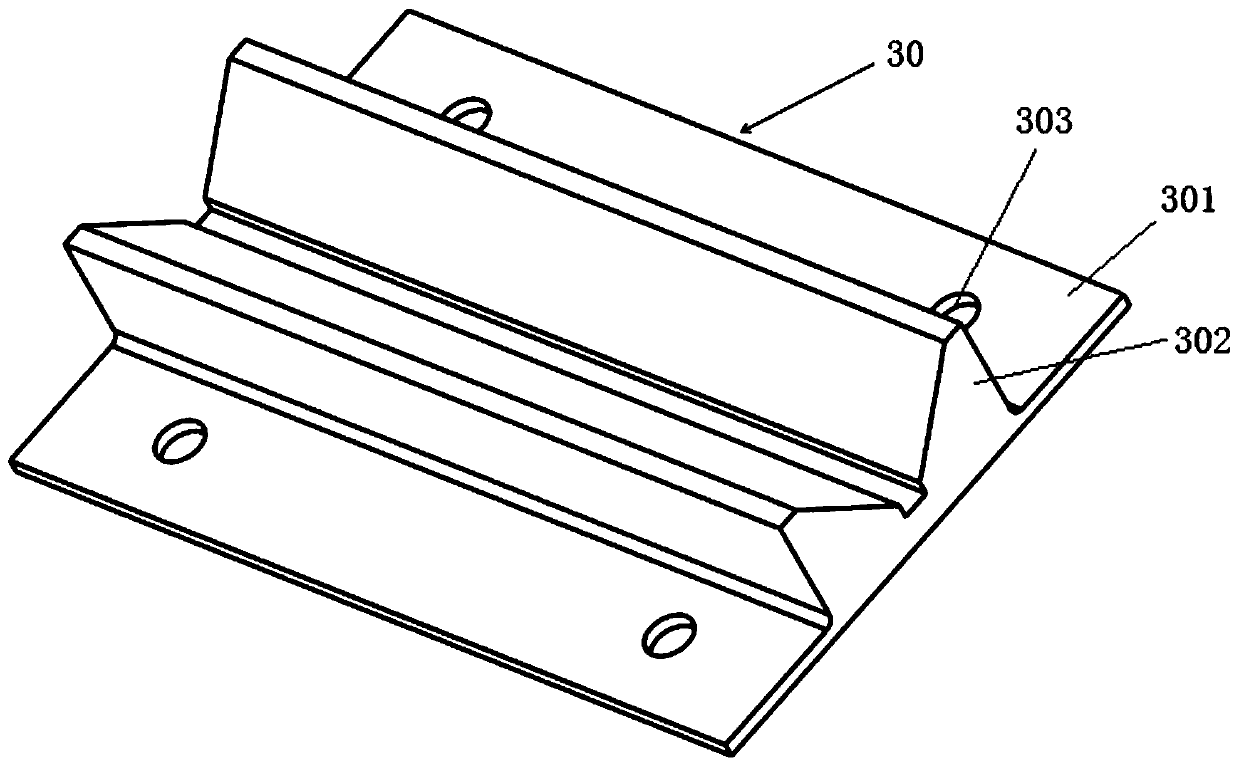

[0036] Such as figure 1 As shown, a rotary welding positioning device for a lithium-ion cylindrical battery cover plate includes a base 10, and the central axis of the base 10 is sequentially fixed with a front clamping member 20, a positioning assembly 40 and a rear clamping member 50; as Figure 5-8 As shown, the positioning assembly 40 includes an outer cylinder 401, and the two sides of the outer cylinder 401 are symmetrically fixed with a connecting plate 403 connected with the base 10; the inside of the outer cylinder 401 is provided with three positioning plates 402 along its axial direction. , the back side of the positioning plate 402 is fixedly connected with the cylinder wall of the outer cylinder 401 through the spring 4026; The arc-shaped end plate 4022 extending in the direction of the cylinder wall of the cylinder 401, all the end plates 4022 are located out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com