Intelligent control type building facility

A construction equipment and intelligent control technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low safety, complex structure, single function, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

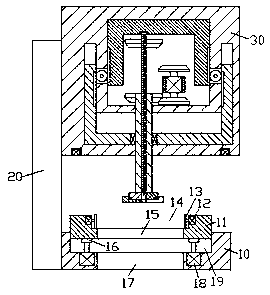

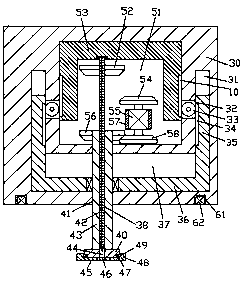

[0011] Combine below Figure 1-2 The present invention will be described in detail.

[0012] refer to Figure 1-2 , an intelligently operated construction equipment according to an embodiment of the present invention, comprising a clamping base 10 and a processing frame 30 installed on the upper side of the clamping base 10 through a support arm 20, the inner wall of the processing frame 30 The body is provided with a sliding cavity 37, and the processing frame 30 at the top of the sliding cavity 37 is provided with a transmission cavity 51, and a U-shaped slide plate 53 is installed in the transmission cavity 51, and the left and right sides of the sliding cavity 37 are The inner wall is symmetrically provided with a control sliding cavity 31 extending upwards. A sliding plate 36 is slidably fitted in the sliding cavity 37, and a control sliding plate fixedly connected with the sliding plate 36 is slidably mounted in the control sliding cavity 31. 35, the control slide cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com