Cutter change mechanism for elevated gantry machining center

A tool changing mechanism and gantry technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem of not being able to adapt to the tool changing structure, solve the problem of tool magazine location layout and protection layout, and solve the problem of loading and unloading. Workpieces, the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

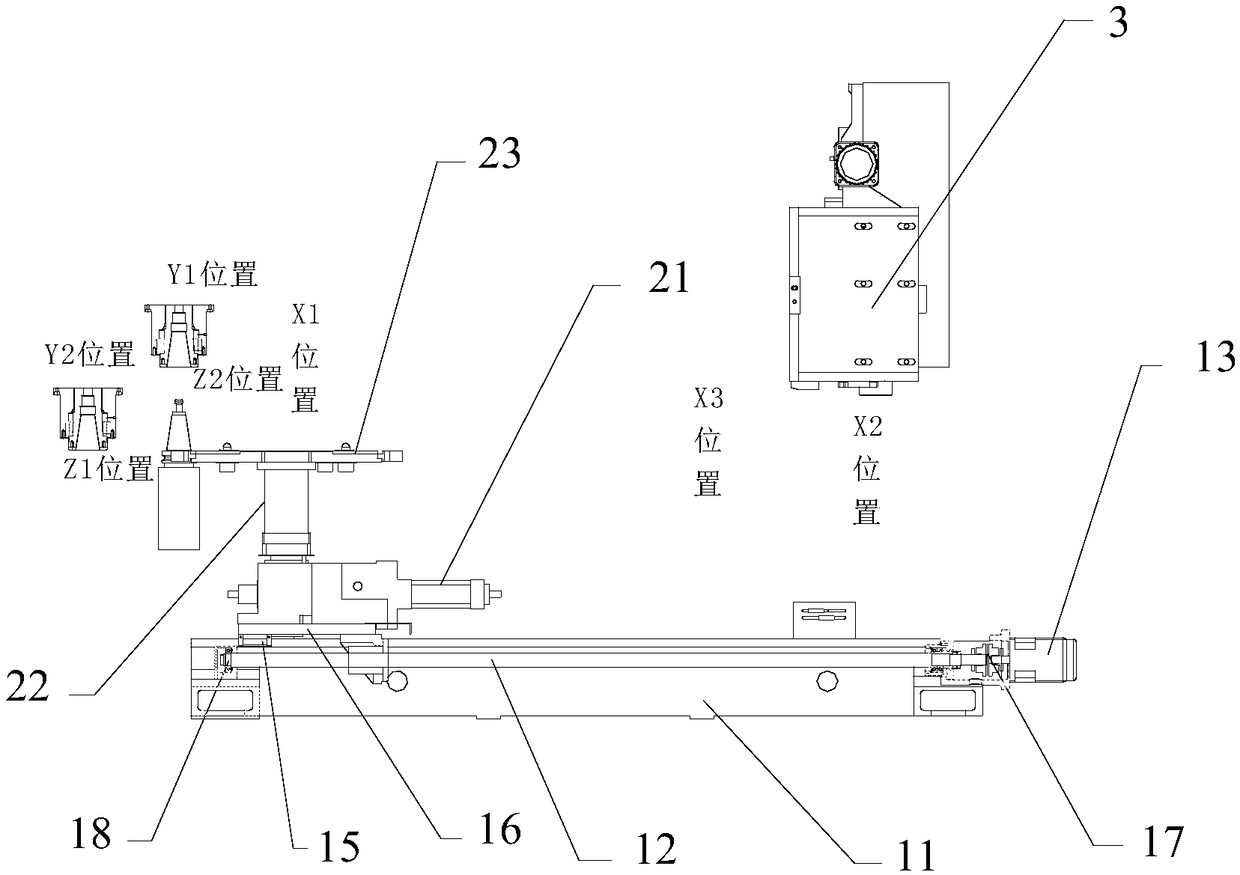

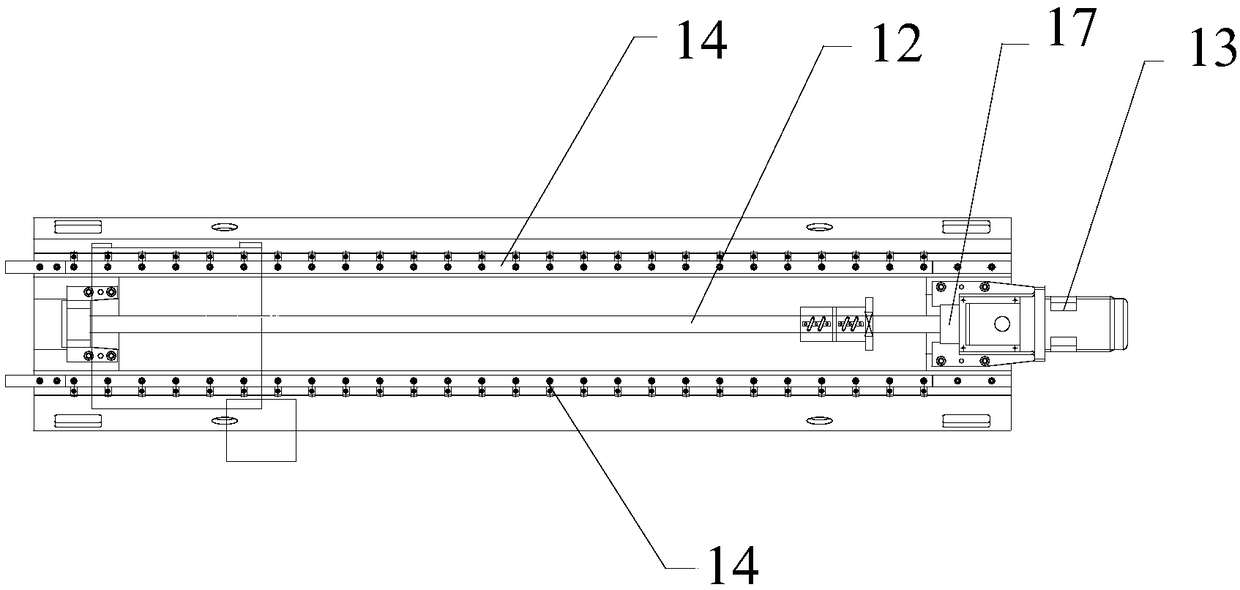

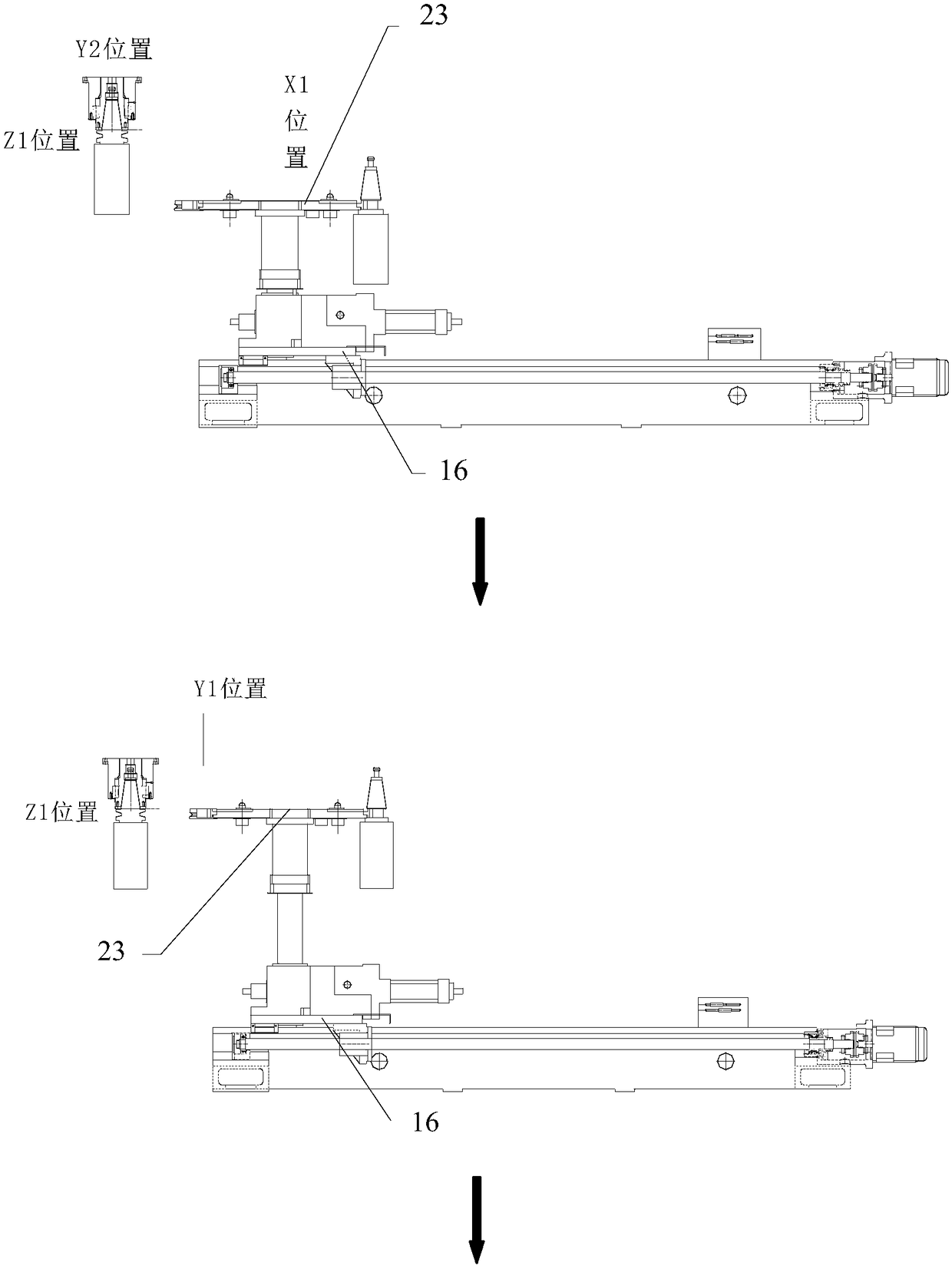

[0025] Such as Figure 1-2 As shown, a tool changing mechanism for an overhead gantry machining center includes a moving device 1 and an ATC manipulator 2 arranged on the moving device 1 .

[0026] The moving device 1 includes a frame 11, on which a lead screw 12 is arranged, one end of the lead screw 12 is connected with the output shaft of the servo motor 13 through a coupling 17, and bearings 18 are arranged at both ends of the lead screw 12. Two guide rails 14 parallel to the leading screw 12 are arranged on both sides of the leading screw 12 , a linear slide 15 is arranged on the guide rail 14 , a workbench 16 is arranged on the linear slide 15 , and the lead screw 12 is connected to the lower end of the workbench 16 .

[0027] ATC manipulator 2 comprises the rotary oil cylinder 21 that is arranged on the workbench 16, is arranged on the lift cylinder 22 above the rotary oil cylinder 21 and is arranged on the manipulator 23 that is used for loading and unloading cutter on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com