Limiting device for bent portion of cloth rack conveying chain

A technology for conveying chains and chain curved parts is applied in the field of limit devices, which can solve the problems of inconvenient operation, inability to disengage the clothes hanger rollers, and increase the difficulty of picking up and clipping fabrics, so as to achieve a lightweight and convenient hanging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

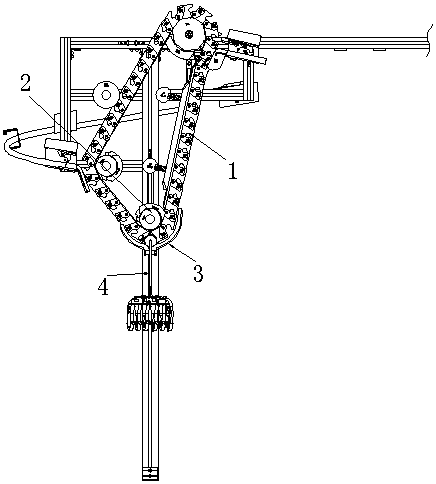

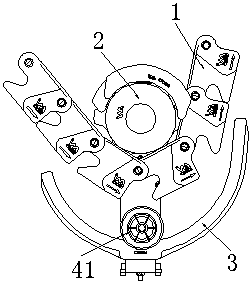

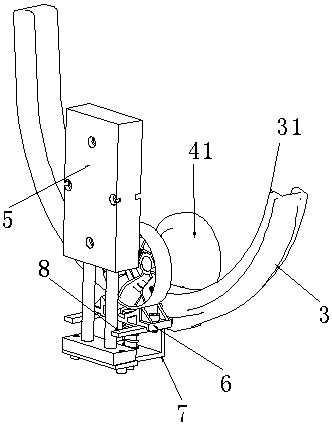

[0025] In conjunction with the accompanying drawings, the limit device for the curved part of the clothes hanger conveying chain is set on the outside of the curved part of the conveying chain 1 in the garment hanging system, which can play a role of limiting, so that the clothes hanger 4 can pass through the guardrail smoothly under the conveying chain 1 3 positions. The conveyor chain 1 is used in the garment hanging system to lift and transport the hangers 4. At the workstation position of the garment hanging system, the connection between the ring rail and the workbench can be established by setting the conveyor chain 1 , to realize the delivery of the clothes hanger 4 between the ring track and the workbench. The conveyor chain 1 is a closed structure composed of several chain plates hinged together head to tail. A clamp for clamping the hanger roller 41 is formed between two adjacent chain plates. The clamp on the straight-line portion of the conveyor chain 1 The mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com