Laminated bridge crane

An overhead crane and stacking technology, which is applied in the directions of traveling overhead cranes, cranes, and traveling mechanisms, can solve the problems of increasing the length of the grinding workshop and increasing the investment in civil engineering, and achieves the effect of reducing investment and saving height differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

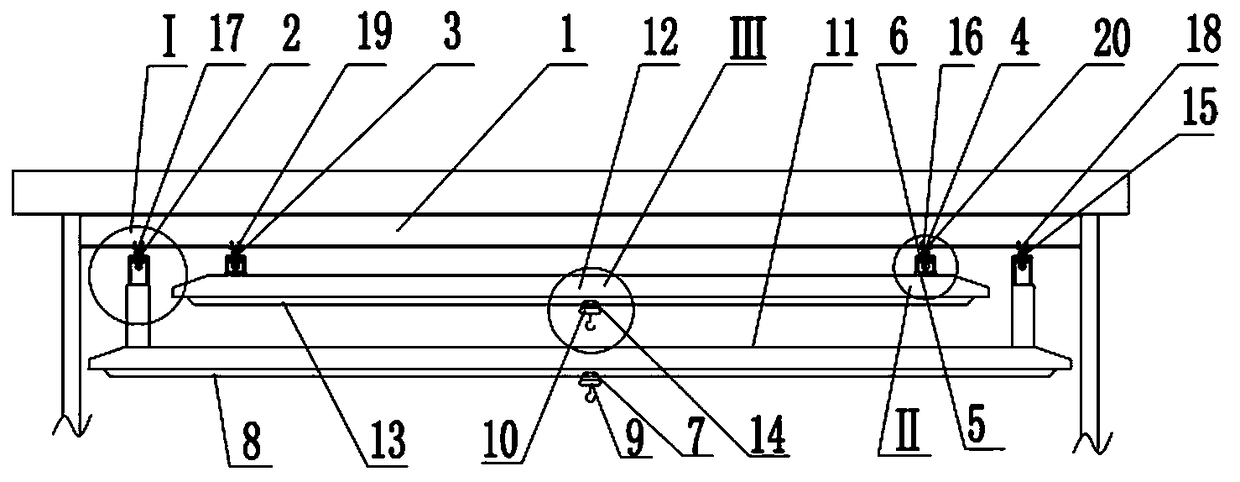

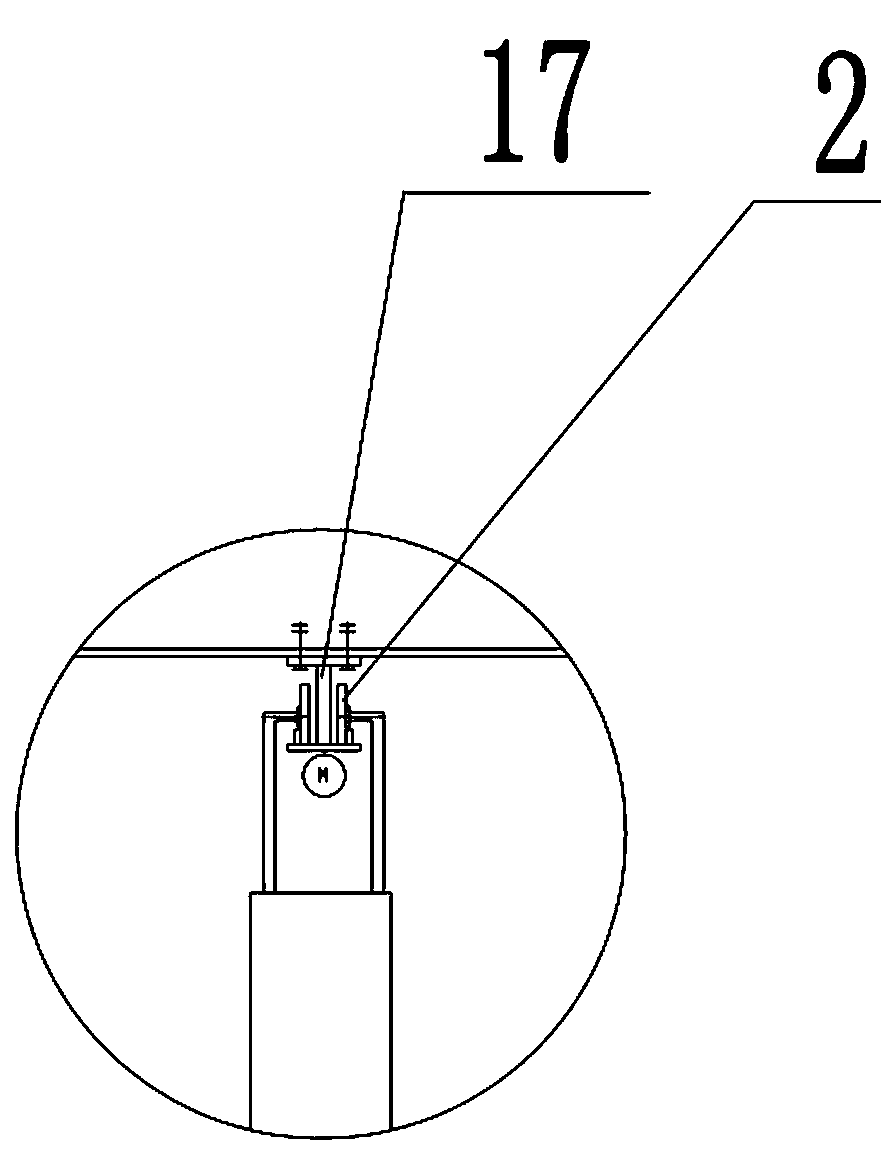

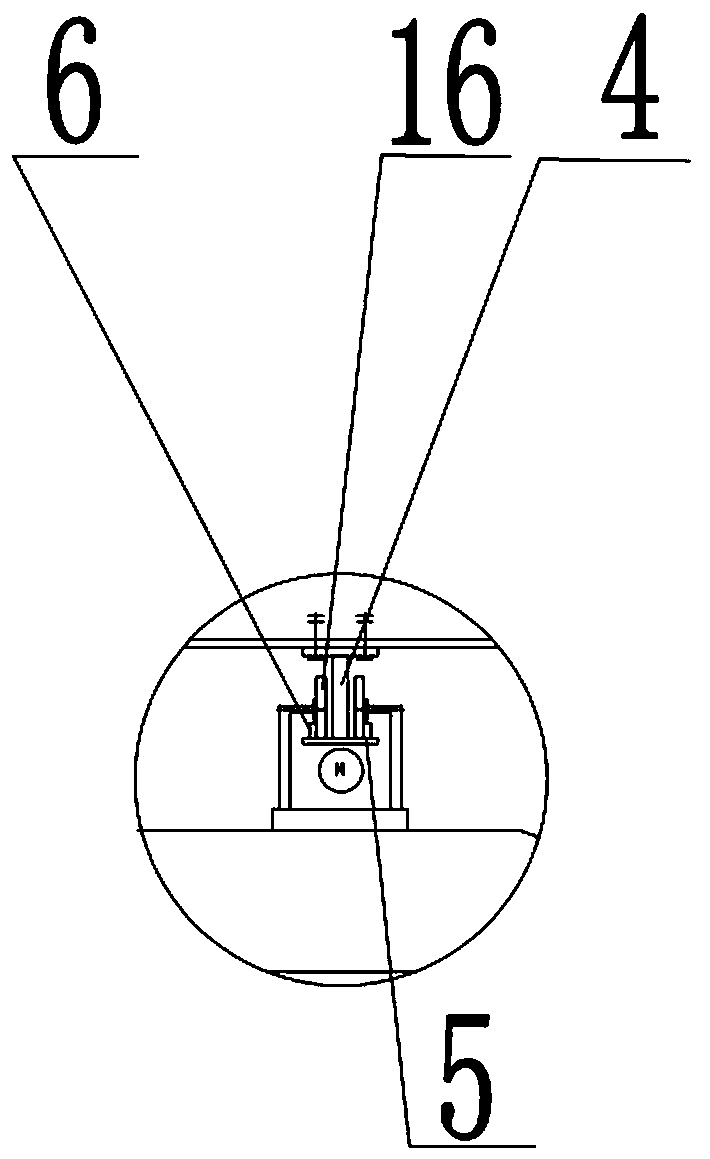

[0026] Such as figure 1 , 2 , 3 and 4, the stacked bridge crane of the present invention is characterized in that it includes a suspension system A and a suspension system B arranged in a staggered height, and the suspension system B is arranged above the suspension system A and is located at In the space surrounded by the suspension system A and the load-bearing beam 1,

[0027] The suspension system A includes the cart beam I17 and the cart beam II18 arranged under the load-bearing beam 1 of the workshop, and the walking passages respectively arranged on the cart beam I17 and the cart beam II18, through which the wheel set of the cart travels I and the trolley walking wheel group II are suspended on the bridge crane A11 on the said trolley beam I17 and the trolley beam II18, and the trolley track A8 set on the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com