Bypass flue gas flow spray drying desulfurization wastewater treatment device and method

A desulfurization wastewater and bypass flue technology, applied in the field of environmental engineering, can solve the problems of increased maintenance costs, complex membrane technology systems, affecting the operation of the main engine, etc., to achieve no maintenance, light nozzles, easy to clean and replace. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

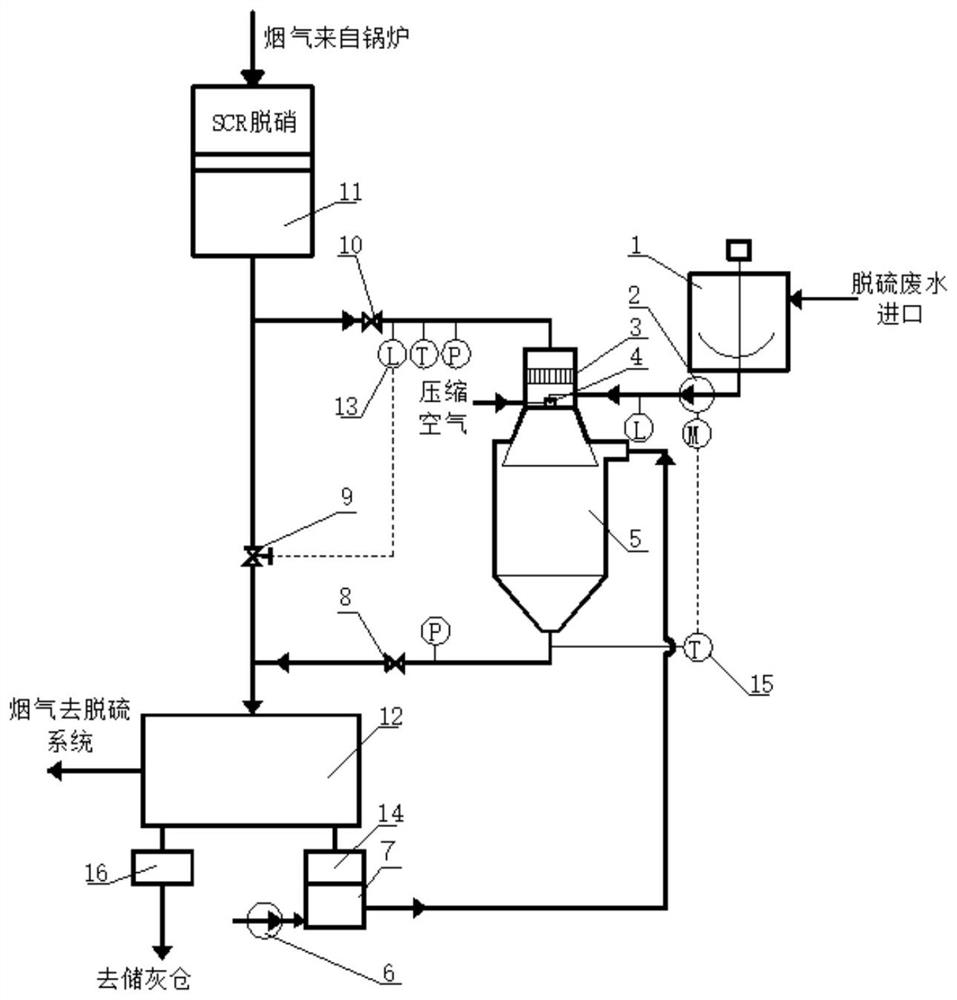

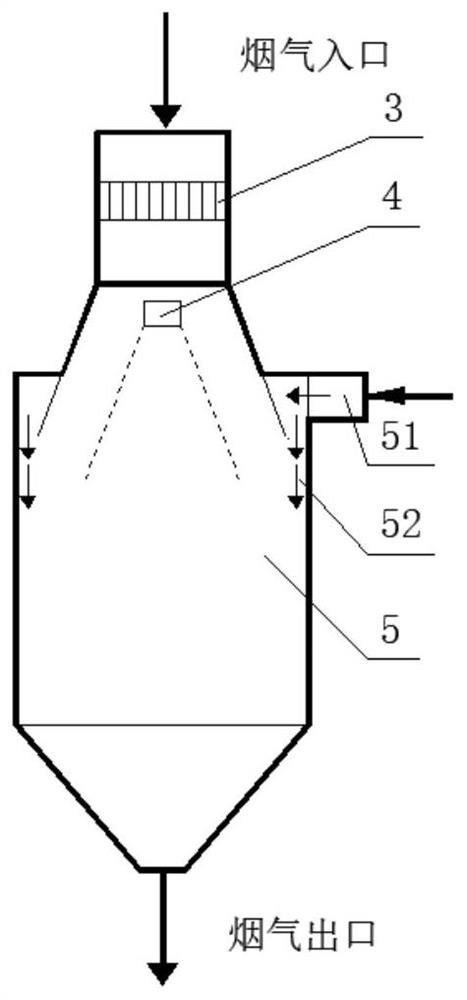

[0036]A bypass flue airflow spray drying desulfurization wastewater treatment method. After the flue gas comes from the boiler air preheater, the temperature is about 120℃. The device is composed of a flue gas distributor 3, an airflow nozzle 4, and an airflow spray tower 5. The lower part of the flue gas distributor 3 is connected with the upper part of the airflow spray tower 5. The airflow nozzle 4 is arranged on the inner central axis of the airflow spray tower 5, and is separated from the flue gas distributor 3 by 100-500mm. The flue gas distributor 3 The inlet flue is equipped with a flue gas flow meter to control the regulating valve 9 on the main flue. The waste water entering the airflow nozzle 4 is sent in by the waste water pump 2, and the flow rate of the waste water pump 2 is determined by the outlet flue temperature at the bottom of the airflow spray tower 5. The meter 15 measures the temperature adjustment, and the outlet smoke thermometer 15 has a temperature adjustm...

Embodiment 2

[0038]A bypass flue airflow spray drying desulfurization wastewater treatment method and device. The flue gas comes from the boiler economizer and after the SCR is out of stock, the temperature is about 350℃. When the boiler is operating under normal load conditions, the resistance of the air preheater is greater than the resistance of the spray tower , Open the regulating valve 9 and adjust the second on-off valve 10 to realize that the measurement value of the flue gas flow meter 13 entering the spray tower reaches the set value. When operating under low load conditions, the resistance of the air preheater is less than the resistance of the spray tower. Open the second switch valve 10, adjust the control valve 9 on the main flue, and also realize that the measurement value of the flue gas flow meter 13 entering the spray tower reaches the set value; the temperature adjustment range of the outlet flue gas thermometer 15 is also 90- 100°C.

Embodiment 3

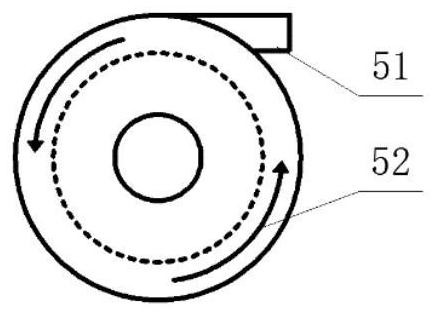

[0040]The bypass flue gas flow spray drying desulfurization wastewater treatment device is composed of a flue gas distributor 3, a gas flow nozzle 4, and a gas spray tower 5. The lower part of the flue gas distributor 3 is connected with the upper part of the gas spray tower 5, and the gas flow nozzle 4 Set on the inner central axis of the airflow spray tower 5, 100-500mm apart from the flue gas distributor 3, the flue gas distributor 3 is equipped with a flue gas flow meter 13 on the flue gas duct to control the regulating valve 9 on the main flue gas duct , The waste water entering the airflow nozzle 4 is sent in by the waste water pump 2, and the flow rate of the waste water pump 2 is adjusted by the metering temperature of the outlet flue gas thermometer 15 provided at the bottom of the airflow spray tower 5. The airflow spray tower 5 is provided with a fly ash inlet 51 on the top of the straight cylinder, and the fly ash inlet 51 is tangentially connected with the airflow spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com