Traffic Engineering Construction Windproof and Dust Suppression Net

A wind-proof and dust-suppressing net, traffic engineering technology, applied in protective equipment, using liquid separating agent, construction, etc., can solve problems such as troublesome installation and disassembly, poor dust filtering effect, single structure of wind-proof and dust-suppressing net, and achieve simple installation , increase ornamental, good spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

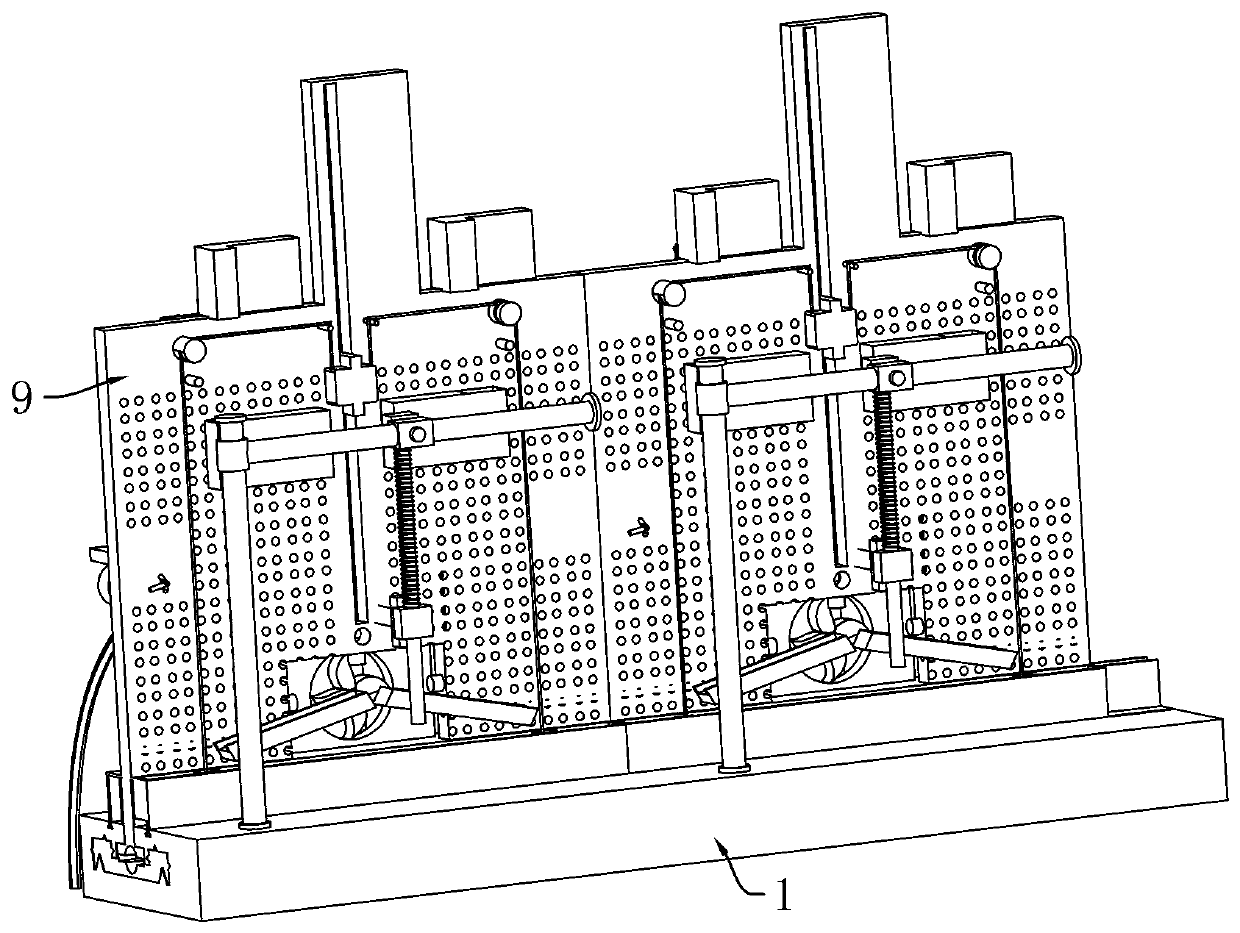

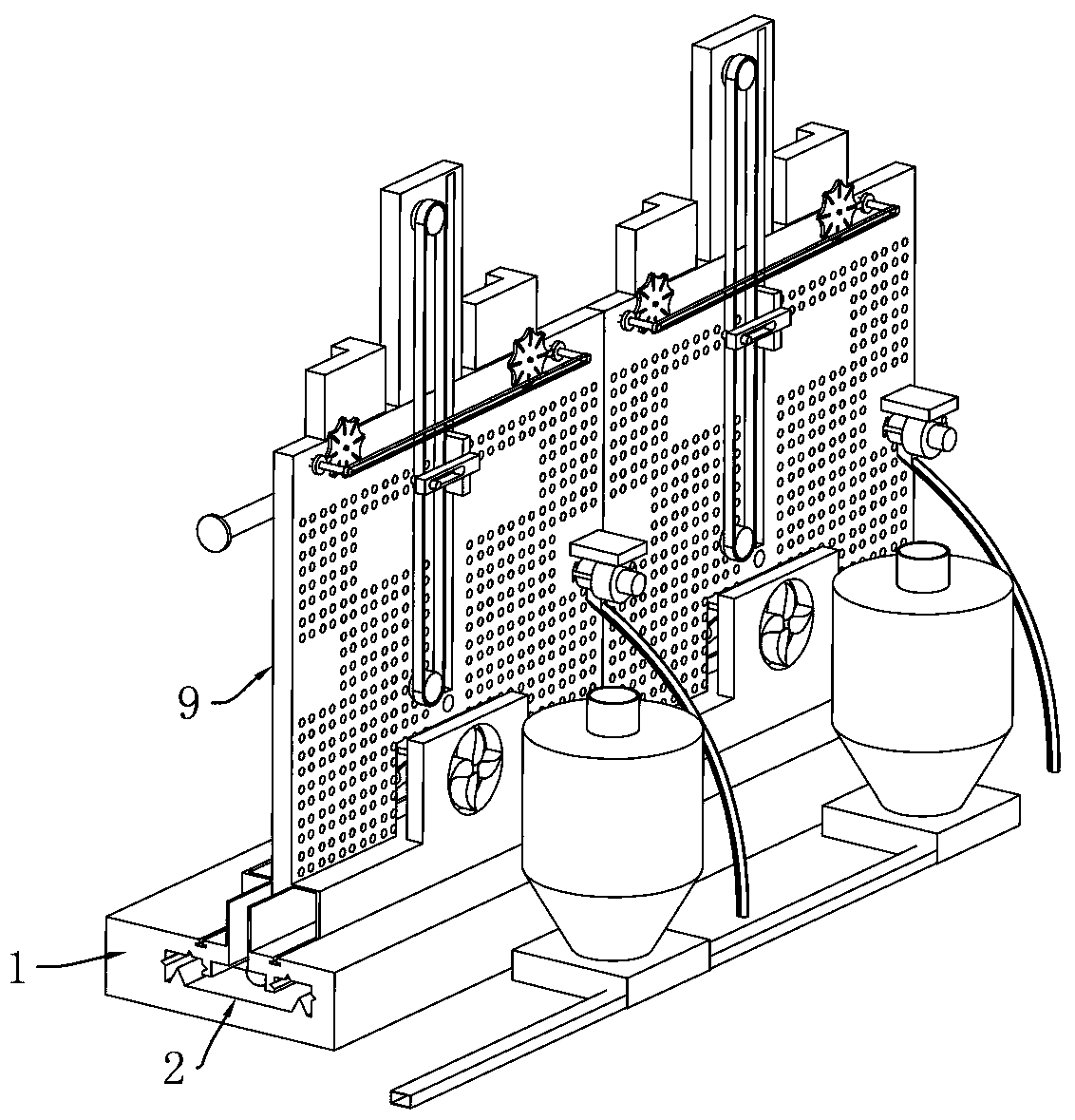

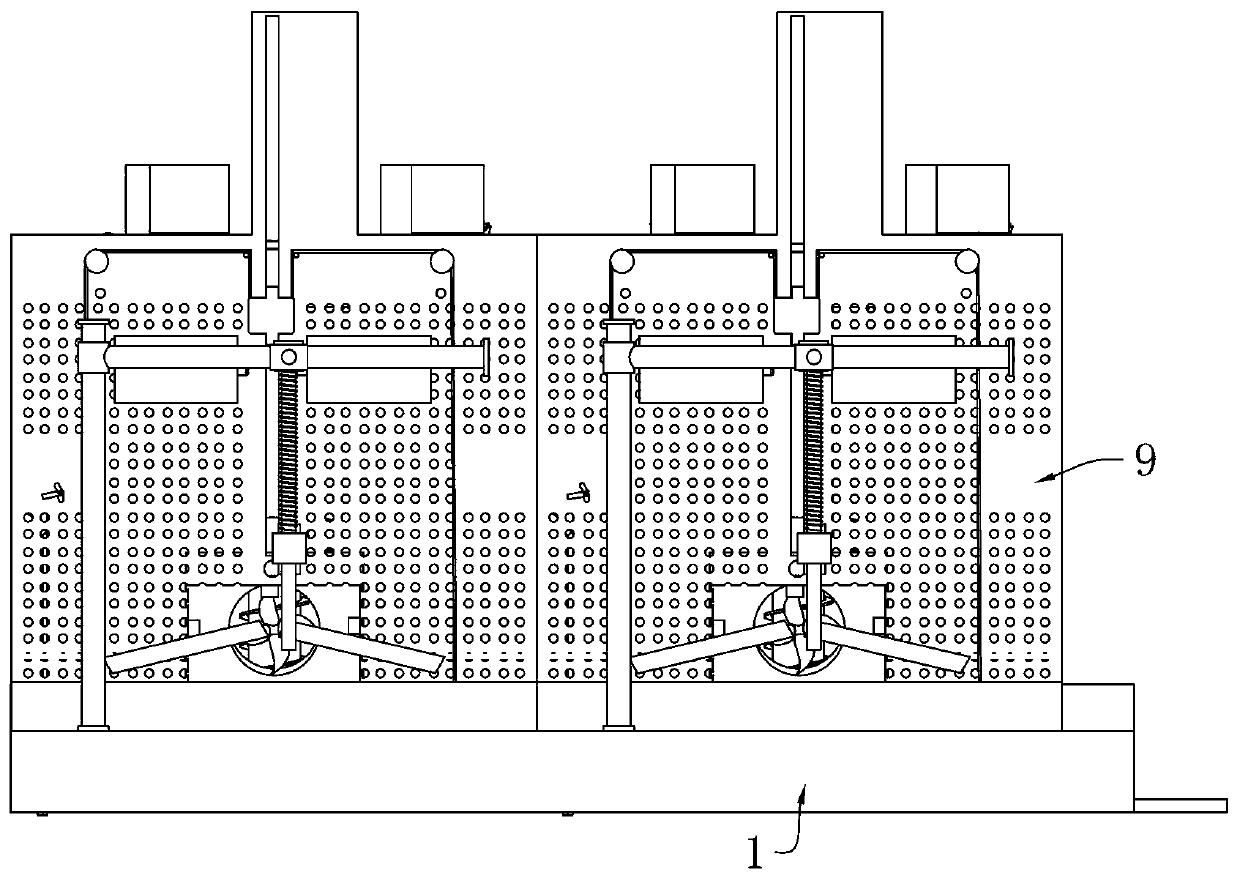

[0054] Embodiment one, the present invention is the windproof dust suppression net of traffic engineering construction, and windproof dust suppression net itself is a kind of prior art, can be divided into two kinds according to its material, and a kind of is the gauze class of soft material, and a kind of is The plate type of hard material, and what the present invention uses is the wind-proof and dust-suppressing net of hard material, in order to facilitate the installation of the wind-proof and dust-suppressing net, the present invention includes a plurality of bottom shells 1, and each bottom shell 1 Corresponding to a windproof and dust-suppressing net 9, the bottom shell 1 is fixed on the ground with bolts during installation, or buried on the ground, and an installation groove 2 is opened on the upper end surface of the bottom shell 1. The overall structure of the installation groove 2 is T T-shaped groove 3 is mainly used to place windproof and dust-suppressing net 9. T...

Embodiment 2

[0061] Embodiment 2. On the basis of Embodiment 1, reinforcement plates 19 placed on both sides of the windproof and dust suppression net 9 are arranged above the bottom shell 1. The reinforcement plates 19 are L-shaped. One end of the reinforcement plate 19 is connected to the windproof and dust suppression net. The net 9 is fixedly connected, and the other side of the reinforcing plate 19 is slidably connected to the upper surface of the bottom shell 1, and the fixed part of the windproof and dust suppression net 9 is placed at the lower end. Stable, so the opening on the T-shaped slot 3 is integrally connected with an anti-fall plate 20 that places the windproof and dust suppression net 9 inside. The height of the anti-fall plate 20 can effectively prevent the windproof and dust suppression net 9 from falling, and the anti-fall plate The upper end of 20 is placed in the reinforcing plate 19 of L shape and contacts with reinforcing plate 19, can be sleeved with torsion spring...

Embodiment 3

[0062] Embodiment 3, on the basis of Embodiment 1, a plurality of fixed columns 22 are fixed on the slightly lower end of the rear side of the windproof and dust suppression net 9, and a compression plate placed above the windproof and dust suppression net 9 is fixed above the fixed columns 22 23. A support column 24 is movable on the fixed column 22. The lower end of the support column 24 is integrally connected with a support bar 25. The support bar 25 is curved and protrudes outward. The front side of the support column 24 is integrally connected with a windproof The pressing plate 26 of the dust suppression net 9, the pressing plate 26 can pass through the through hole of the windproof and dust suppression net 9, and then the end of the pressing plate 26 is rotated and connected with a bead 27 that can be pressed on the windproof and dust suppression net 9, and on the support column 24 The outer side is provided with the cam pressing block 28 that is sleeved on the fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com