Underwater consolidation pile and construction method thereof

A technology of pile body and solidified material, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of limited tensile load, high difficulty, and high construction difficulty, and achieve large bearing capacity, pull-out resistance, and The effect of increased pulling force and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

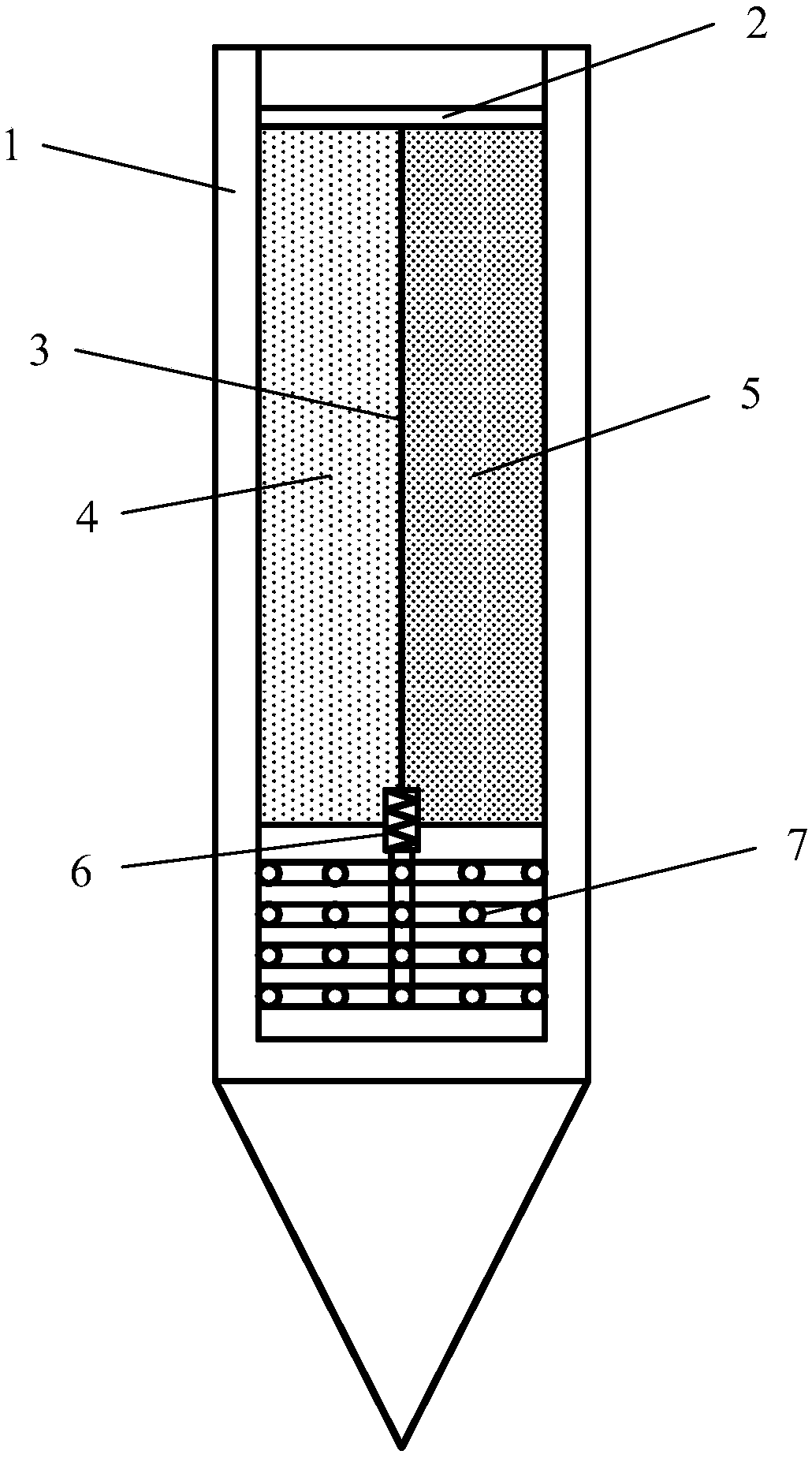

[0029] For the sediment median particle size d 50 =5 μm, the mud with a moisture content of 86%, present embodiment provides a kind of muddy underwater consolidation pile for construction engineering, such as figure 1 As shown, it includes: a pile body 1 , a piston push plate 2 , an isolation component 3 , a first curing material 4 , a second curing material 5 , a mixing component 6 , and a nozzle 7 .

[0030] In this embodiment, the pile body 1 is the carrier of other parts of the pile, and is made of stainless steel; the pile body 1 is composed of a cone body and a column body, the cone body is 0.5m long, and the cylinder body is 2m long. The cross-section of the joint is a circular section with a diameter of 0.38m; the conical body is used as the head of the pile body 1, and the inside of the cylindrical body is a cavity with a length of 1.5m and a diameter of 0.3m. m is provided with a movable piston push plate 2 made of stainless steel with a thickness of 2 cm, and an im...

Embodiment 2

[0041] For the sediment median particle size d 50 = 8 μm, the mud with a moisture content of 75%, present embodiment provides a kind of silty underwater consolidation pile for construction engineering, such as figure 1 As shown, it includes: a pile body 1 , a piston push plate 2 , an isolation component 3 , a first curing material 4 , a second curing material 5 , a mixing component 6 , and a nozzle 7 .

[0042] In this embodiment, the pile body 1 is the carrier of other parts of the pile, and is made of stainless steel; the pile body 1 is composed of a cone body and a column body, the cone body is 0.5m long, and the cylinder body is 2m long. The cross-section of the joint is a circle with a diameter of 0.38m; the cone is used as the head of the pile body 1, and the inside of the cylindrical body is a cavity with a length of 1.5m and a diameter of 0.3m. A movable piston push plate 2 made of stainless steel with a thickness of 2 cm is provided at the center, and an immovable ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com