High-reliability low-temperature refrigerator

A low-temperature refrigerator and reliability technology, which is applied in the direction of refrigerators, gas cycle refrigerators, refrigeration components, etc., can solve the problems of motor 12's deteriorating operating conditions, increased load, and sticking, so as to avoid powder sticking, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

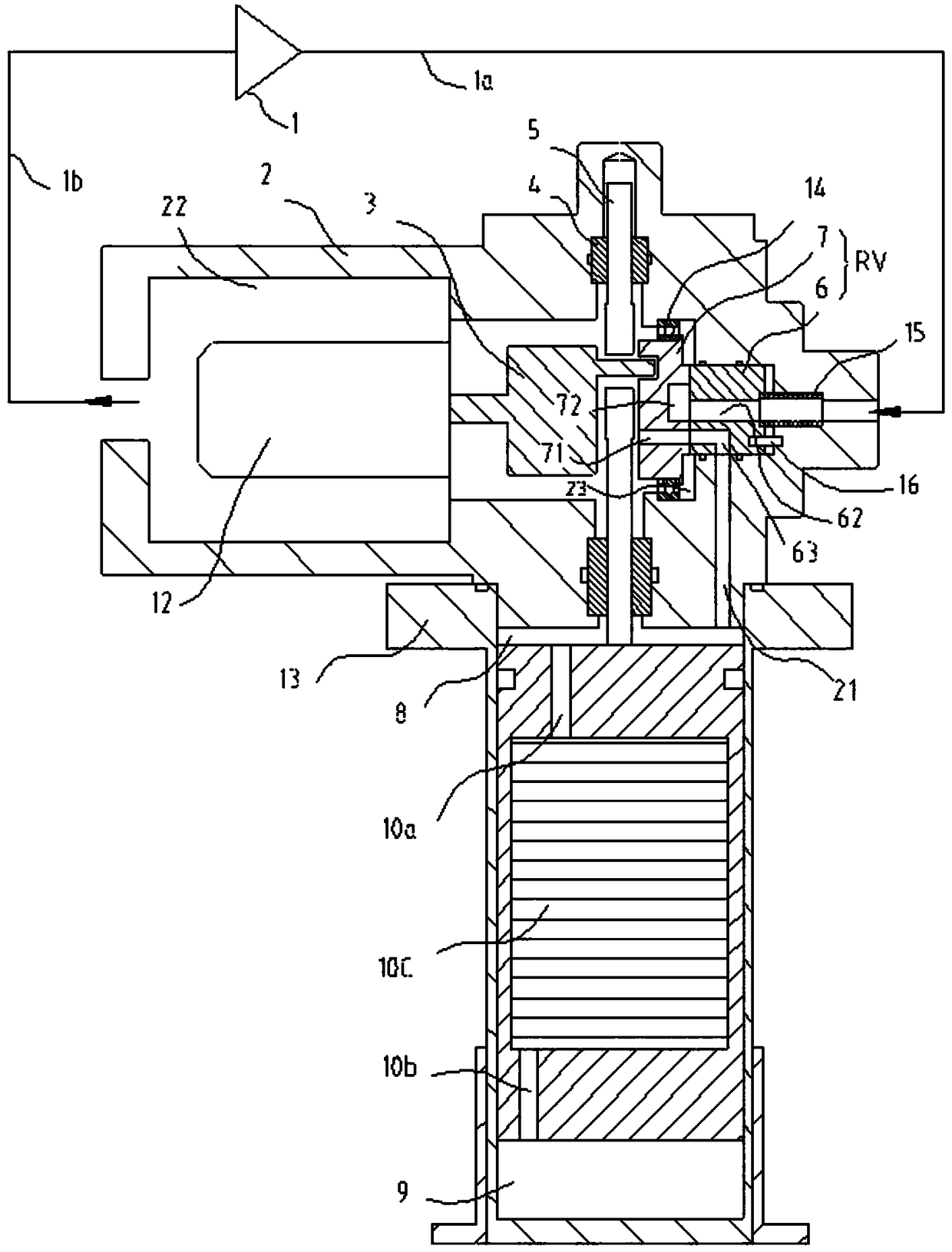

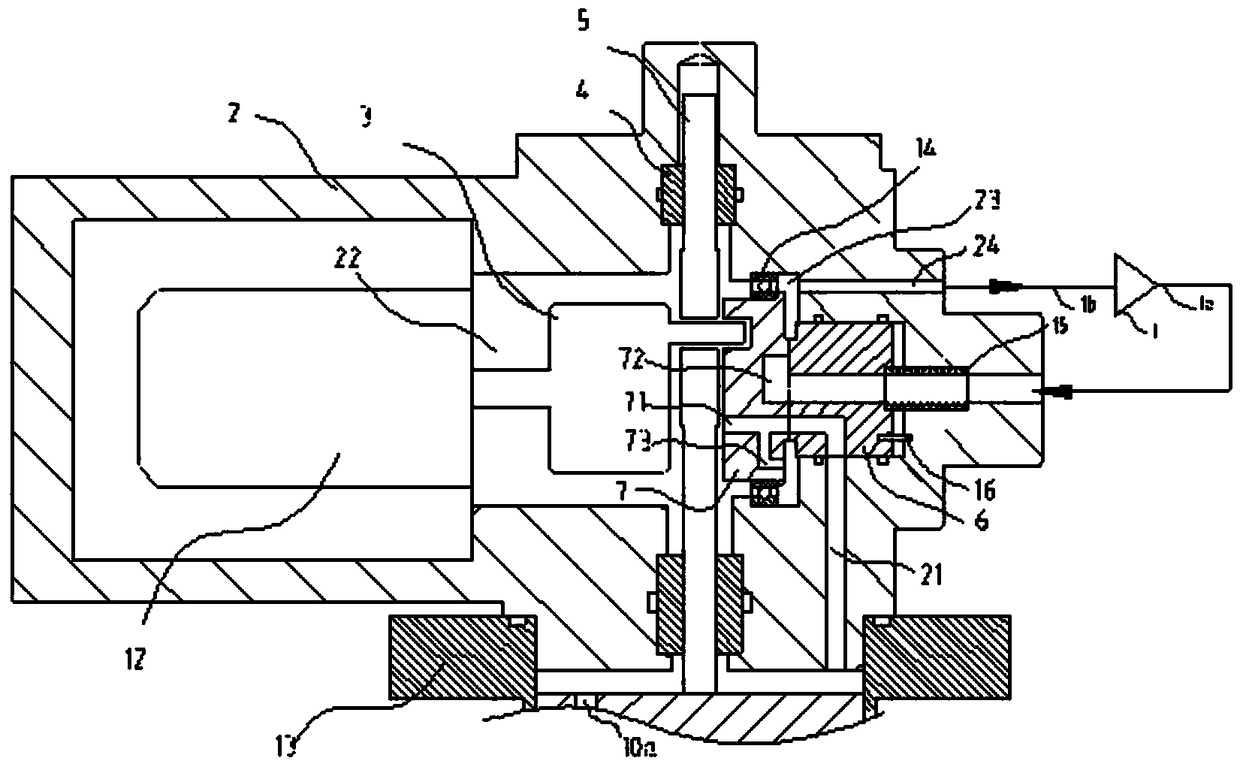

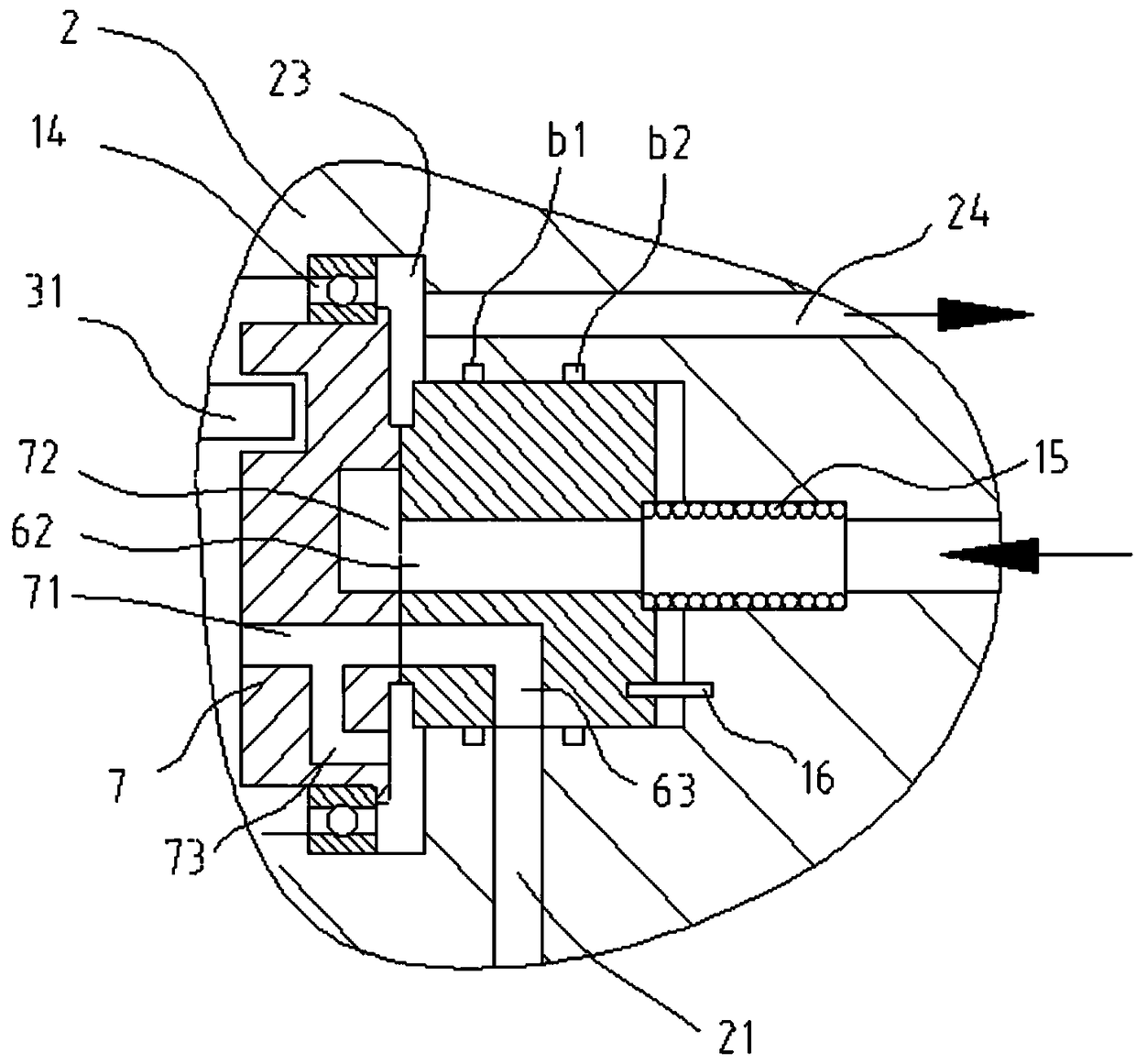

[0027] Such as Figure 2-6 Shown: a high-reliability low-temperature refrigerator, including a compressor 1, a cover assembly 2, an air distribution valve 6, a rotary valve 7, a motor 12, and a cylinder 13, and the surrounding side of the contact surface of the air distribution valve 6 and the rotary valve 7 An annular groove 23 is formed between the inner wall of the cover assembly 2, and the cover assembly 2 at the annular groove 23 is provided with a low-pressure exhaust hole 24 communicating with the annular groove 23. The outlet end of the low-pressure exhaust hole 24 is sucked by a low pressure The gas line 1b is connected to the low-pressure side of the compressor; a low-pressure passage 73 that can communicate with the annular groove 23 is provided on the rotary valve 7, and the other end of the low-pressure passage 73 communicates with the low-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com