Fattening sheep house

A sheep house and sheep pen technology, applied in animal houses, animal feeding devices, animal drinking devices, etc., can solve the problem of low actual utilization rate of automatic feeding equipment, lack of efficiency and safety of group transfer, and large land cost. And feed costs and other issues, to achieve the effect of convenient manure treatment and transfer of sheep, reducing feeding labor, reducing labor labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In this paper, it is divided into upper layer carrier board and lower layer carrier board. If it is only called carrier board, it can be the upper layer carrier board or the lower layer carrier board.

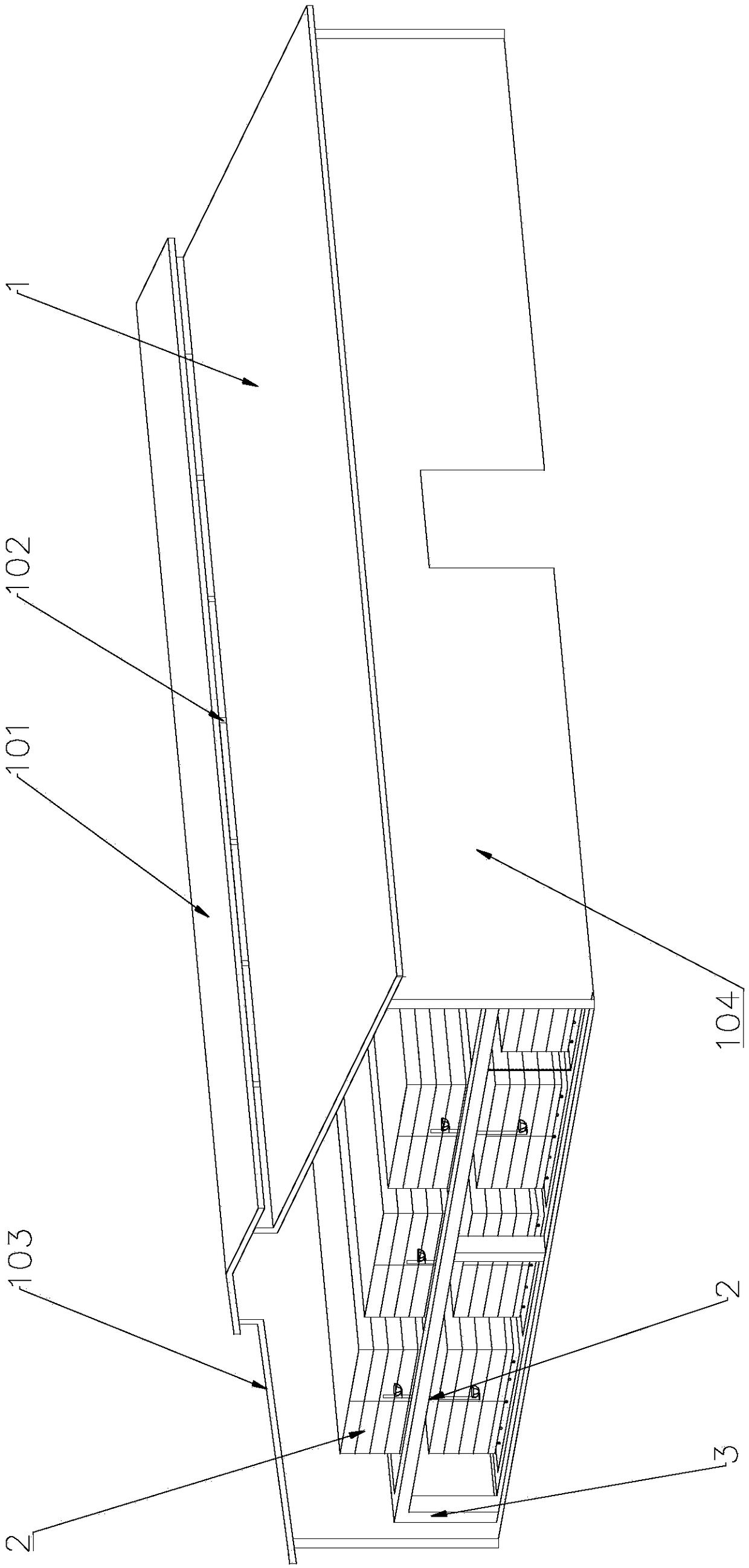

[0034] A sheep house for fattening consists of a sheep house 1 , a movable sheep pen 2 and a sheep pen frame 3 .

[0035] exist figure 1 Among them, the sheep house has a roof and walls. The roof is a double-layer hollow roof, wherein the upper roof 101 is connected with the lower roof 103 through roof pillars 102, and there is a vent between the upper roof and the lower roof to keep the air inside and outside the sheep house unimpeded. Below the roof is a wall 104 enclosed on all sides, and the wall is a steel frame structure.

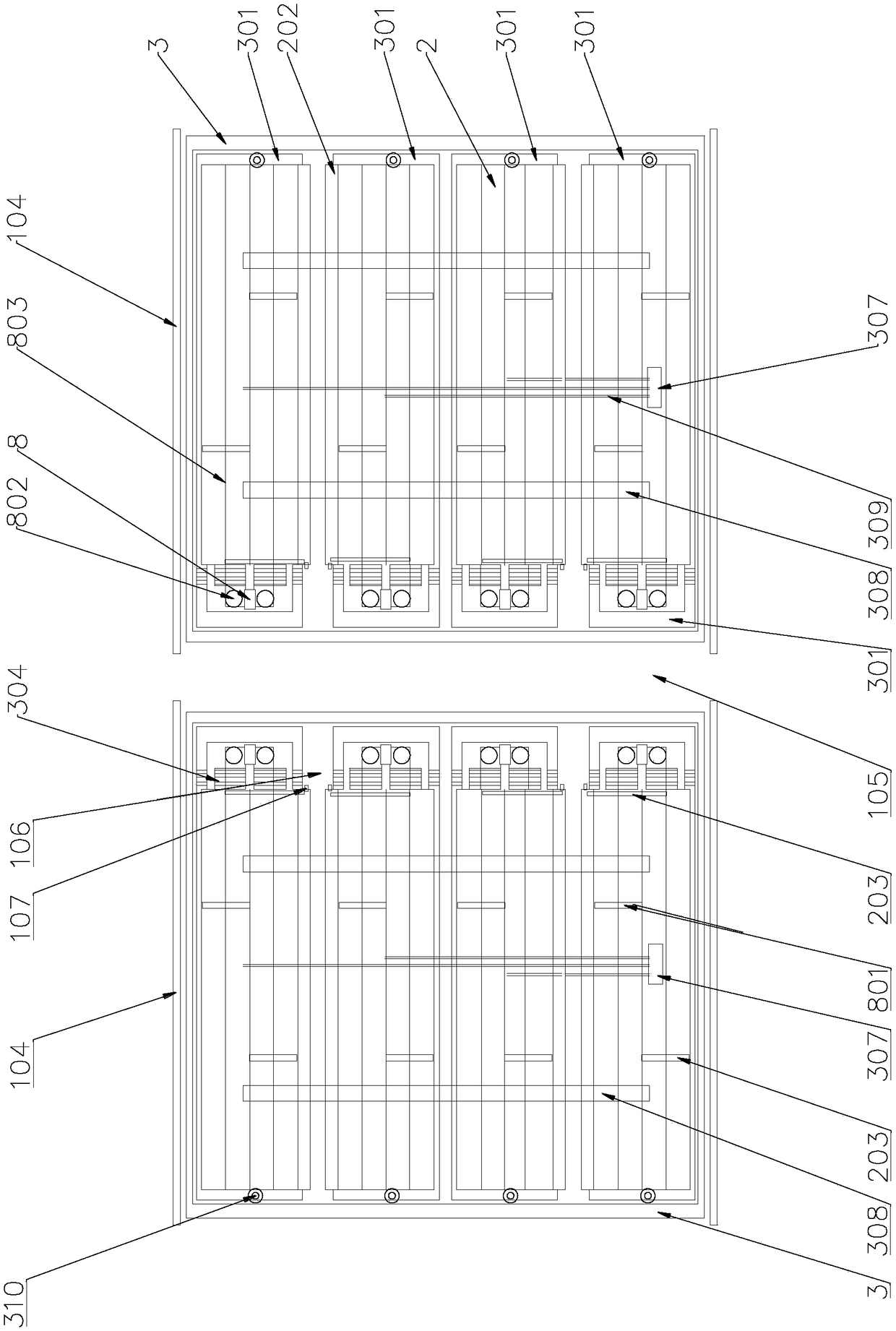

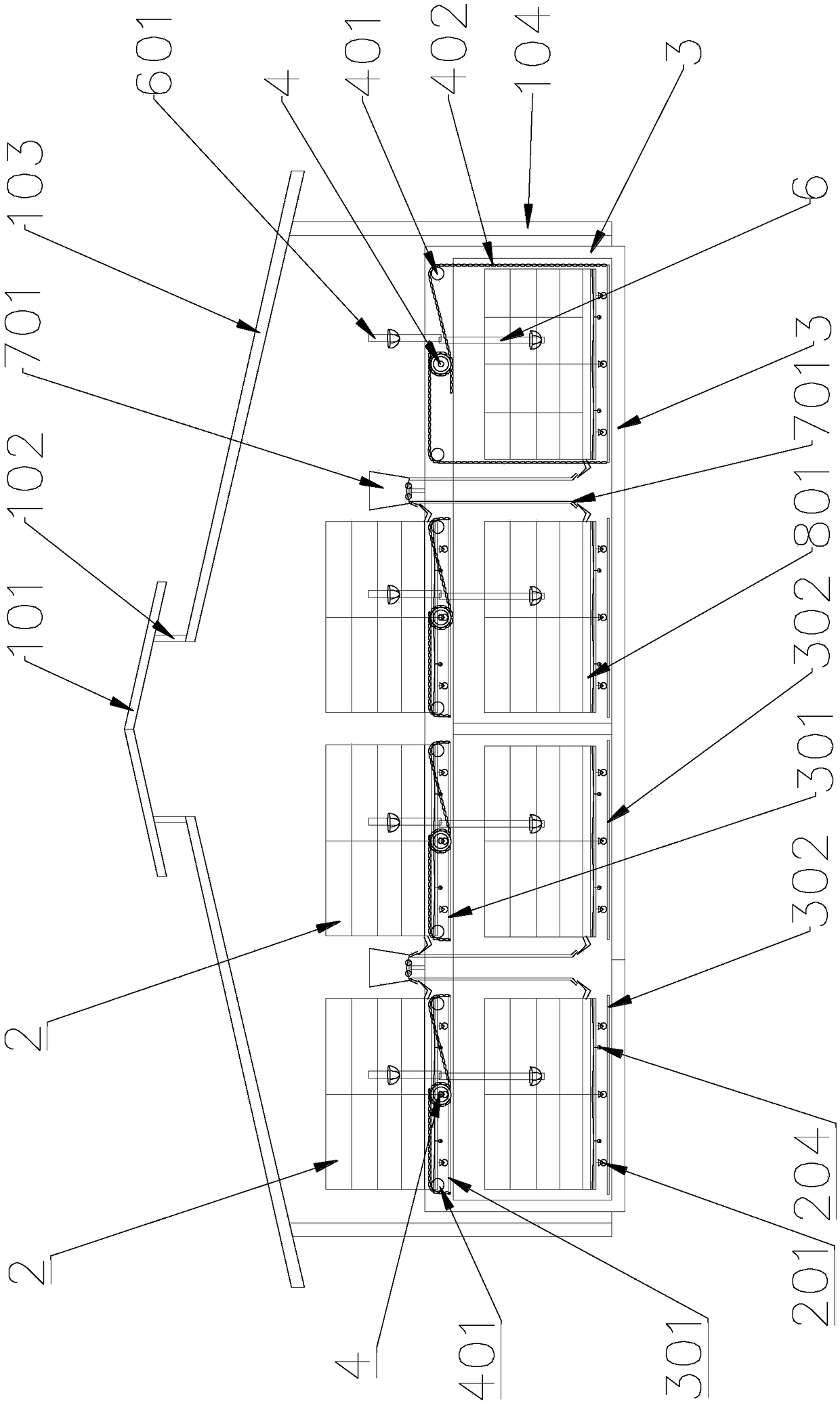

[0036] figure 2 It is the plane layout in the sheep house: a excrement cleaning channel 105 is arranged in the middle of the ground of the sheep house, and the two sheep pen frames 3 equipped with movable sheep pens are symmetrically distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com