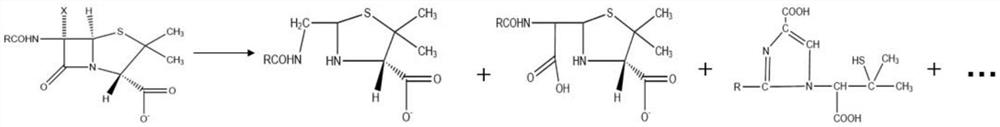

A method for removing residual penicillin antibiotics in biomedical waste residue

A technology of biomedicine and antibiotics, which is applied in the field of removing residual penicillin antibiotics in biomedical waste residues, can solve the problems of high processing and transportation costs, and achieve the effect of fast and efficient removal process, convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Penicillin content is 5800ppm waste residue. Add 93g water, 20g sulfuric acid in 20g waste residue, form the slurry that solid content is 15%; Add 2g catalyst FeSO in the slurry afterwards 4 ·7H 2 O, 6g of oxidant hydrogen peroxide, reacted at 70°C under normal pressure for 3 hours; after separation and drying, 15.14g of a product with a solid content of 70% was obtained, the residual amount of penicillin was detected to be less than 10ppm, and the removal rate reached more than 99%.

Embodiment 2

[0033] The penicillin content is the waste residue of 3812ppm. Add 450g water, 0.5g nitric acid in 50g waste residue, form the slurry that solid content is 10%; Add 0.03g catalyst FeCl in the slurry afterwards 2 , 45g of hypochlorous acid as an oxidant, reacted at 60°C and normal pressure for 2.5 hours; after separation and drying, 32.35g of a product with a solid content of 85% was obtained, and the residual amount of penicillin was detected to be less than 10ppm, and the removal rate reached more than 99%. .

Embodiment 3

[0035] The waste residue with 6-aminopenicillinic acid content of 5000ppm. In 500g waste residue, add 1900g water, 100g sulfuric acid, form the slurry that solid content is 20%; Add 20g catalyst MnCl in slurry afterwards 2 4H 2 O, oxidant potassium permanganate 50g, reacted at 90 ℃ and normal pressure for 1 hour; through separation and drying, the product 333.8g with a solid content of 75% was obtained, and the residual amount of penicillin was detected to be less than 10ppm, and the removal rate reached 99% %above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com