Construction Sand Screening Device

A technology for sand screening and construction, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc. It can solve the problems of reducing construction efficiency, reducing the service life of motors, and inconvenient replacement of screens with different sieve holes, so as to improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

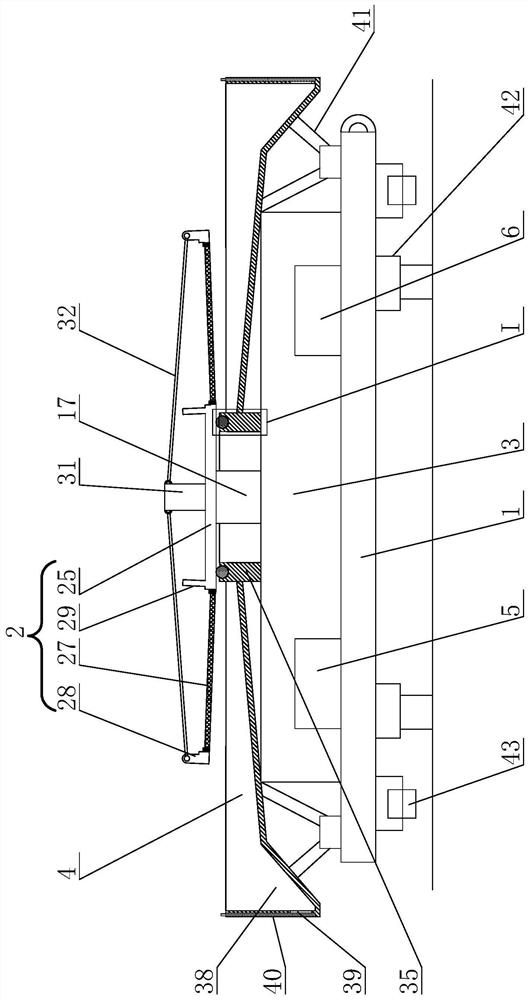

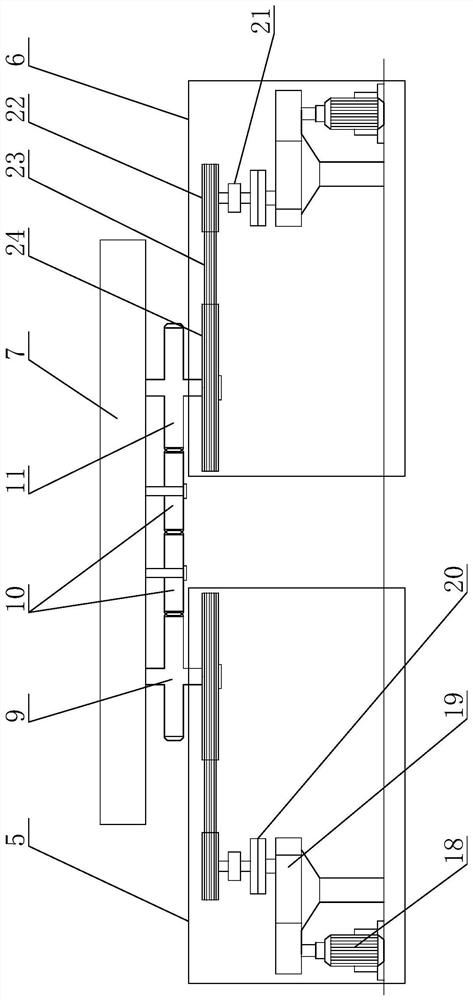

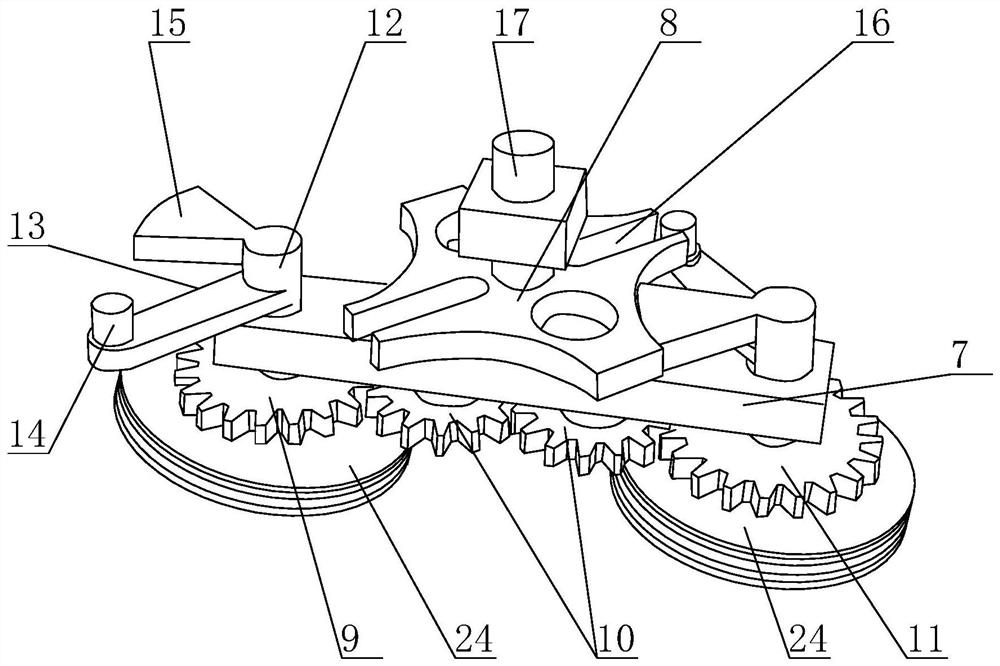

[0050] The present invention is a building sand screening device, as shown in the accompanying drawings figure 1 As shown, the main structure includes a car body 1, a transmission assembly, and a sand screen disc 2. The car body 1 is provided with a transmission box 3, and the transmission assembly is arranged in the transmission box 3, and also includes Deposit sand tray 4, described transmission device assembly comprises left side power device assembly 5, right side power device assembly 6 and sheave drive device assembly. As attached in the manual image 3As shown, the sheave driving device assembly includes a support strip 7, a gear set, a left sheave toggle device, a right sheave toggle device, a middle sheave 8, and said gear set includes a left gear 9, Two connecting gears 10 and a right gear 11, the left gear 9 meshes with the left connecting gear 10, the left connecting gear 10 meshes with the right connecting gear 10, and the right connecting gear 10 meshes with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com