A material with continuously variable thickness in the transverse direction and its preparation method

A variable thickness, horizontal technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve problems such as difficulty, achieve high production efficiency, low raw material cost, and reduce raw material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

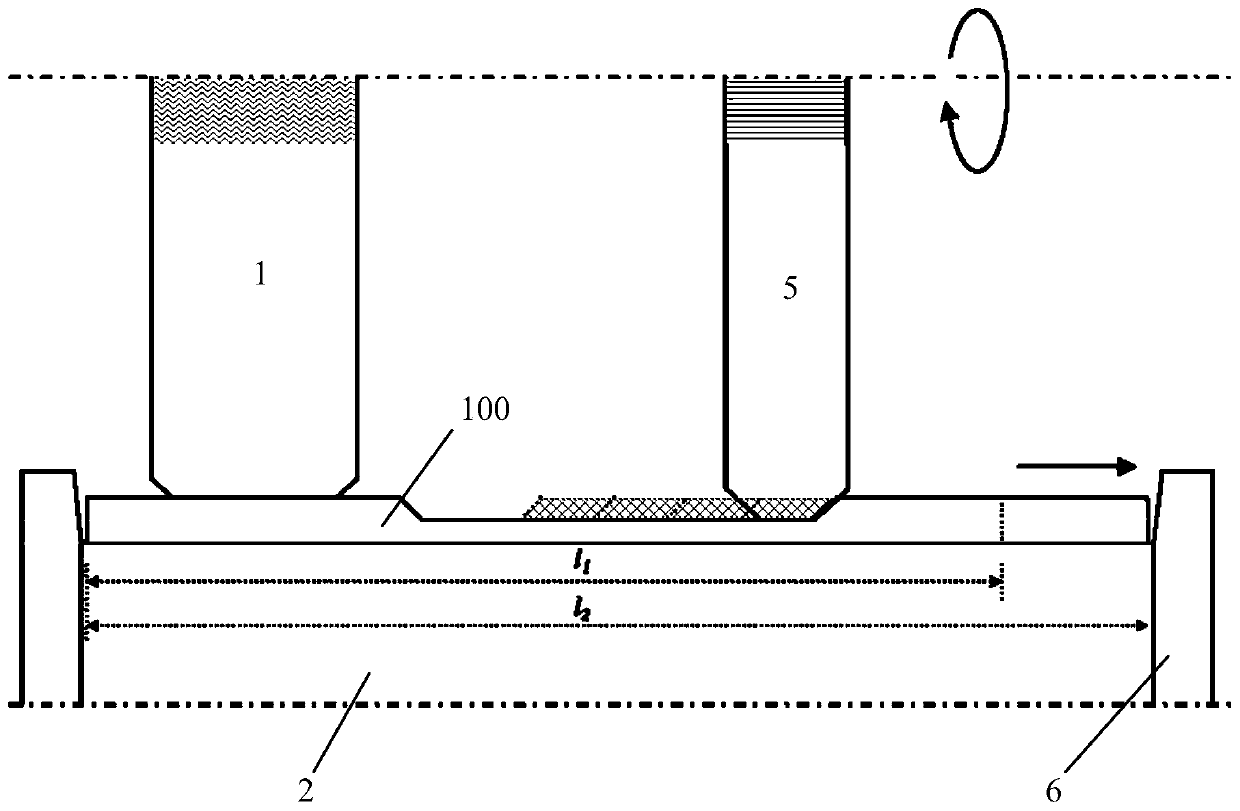

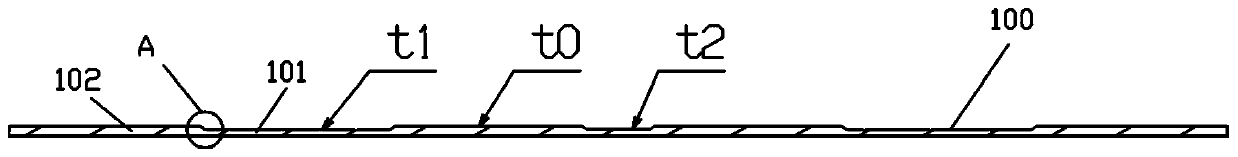

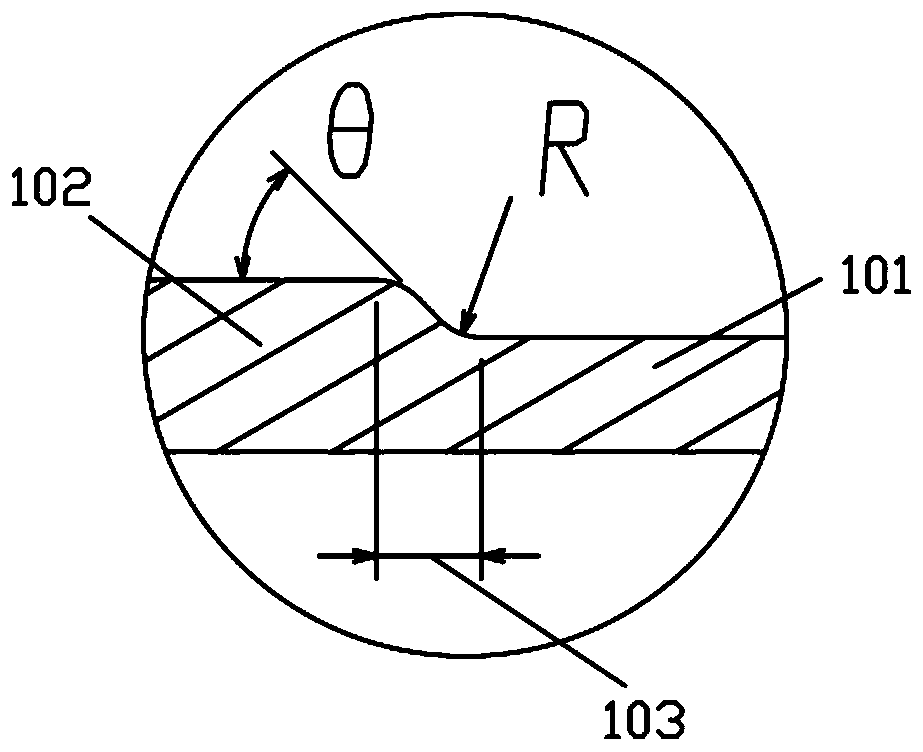

[0032] see Figure 4 ~ Figure 6 , HC420 / 780DP was prepared with lateral variable thickness. The thickness of the raw material is 1.8mm, and the width is 200mm; there are a total of 2 thinning areas, which are symmetrically distributed on the width of the sheet. The thickness requirement is 1.2±0.05mm, and the width requirement is 30±0.5mm (including the transition area).

Embodiment approach

[0033] Its processing implementation method is as follows:

[0034] The preparation process is realized through 3 passes, the rotation speed of the forming tool body 5 in each pass is 540RPM, the sheet feeding speed is 12m / min, the width of each pass is 10mm, and the final sheet width is 219.6mm.

[0035] The material preparation method with transversely continuously variable thickness proposed by the present invention reduces the consumption of raw materials, realizes light weight while meeting the performance requirements of parts; the material unequal thickness processing technology is integrated with the conventional roll forming technology, and the production efficiency is high. The invention can be used for conventional cold-rolled and hot-rolled iron and steel materials, and can also be used for other metal materials such as aluminum alloys and magnesium alloys, and has wide application prospects and economic value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com