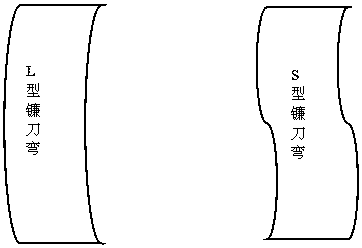

Rapid identification and monitoring method for hot continuous rolling strip steel camber defect

A sickle bend and hot continuous rolling technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of long visual observation distance, inability to accurately obtain the sickle bend of the strip, and affecting the stability of the strip coiling process, etc. problem, to achieve the effect of reducing labor intensity, reducing manual measurement work, and reducing the amount of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Embodiment: After a certain enterprise adopts the method of the present invention, it can quickly identify and monitor the camber defect of hot continuous rolling strip steel, and carry out an alarm display on the operation screen of the computer system of rolling steel to remind the steel rolling operator to adjust in time, and the computer system can detect the steel that exceeds the standard. Volumes are automatically blocked and recorded for overrun lengths. Arrange repair instructions according to the over-standard length, and cut off the out-of-tolerance part to prevent adverse effects on users or subsequent processes.

[0047] The specific parameters are as follows:

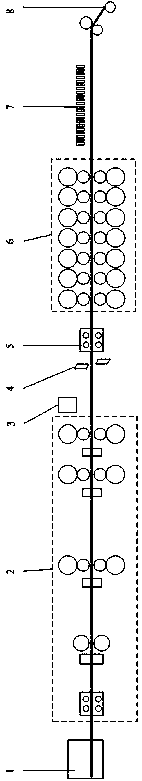

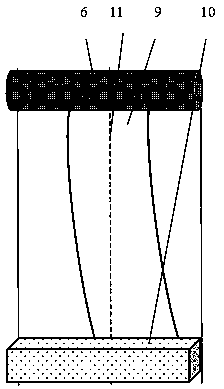

[0048] First, a width gauge is installed at a distance of 3 meters from the exit of the finishing mill; second, the strip runs on the roller table in the laminar cold zone in a free state after leaving the finishing mill and before entering the coiler. The length of the roller table between them is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com