Method for preparing functionally gradient material through axially uniform magnetic field and directional solidification device thereof

A functionally graded material, directional solidification technology, applied in the field of directional melting and casting equipment, metal material technology and solidification equipment, can solve the problems of poor performance, high cost, small size of functionally graded materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

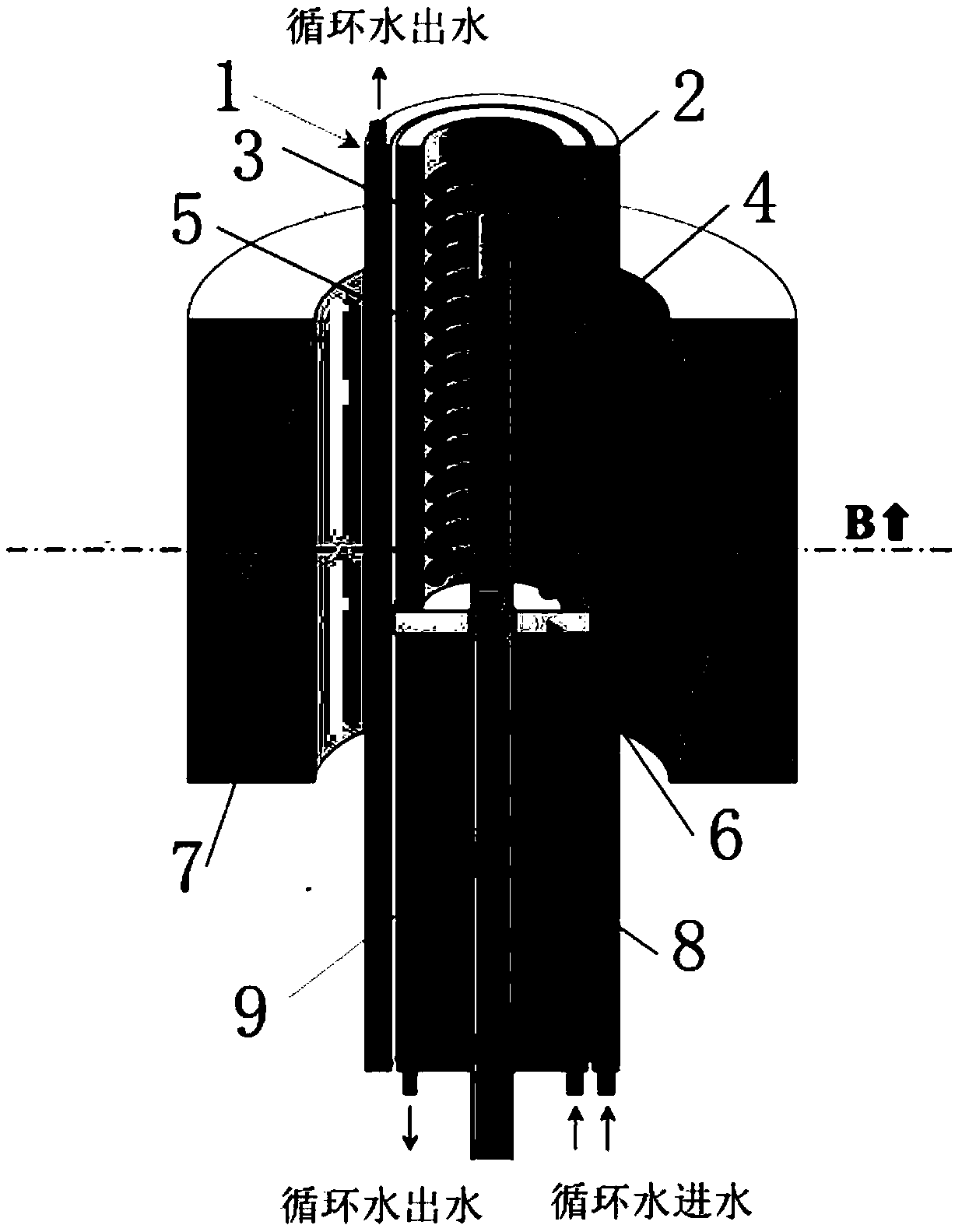

[0049] In this example, refer to figure 1 , a directional solidification device, which utilizes an axial uniform magnetic field to prepare functionally graded materials. The directional solidification device consists of a protective atmosphere input pipe, a water-cooled furnace shell 1, a heating furnace 2, a temperature detection device, a quenching pool 8, a thermal insulation medium 5, and a thermal insulation Layer 6, corundum crucible 3 and pull rod 9, the inner furnace wall of the heating furnace 2 is made of non-magnetic stainless steel, the maximum temperature of the inner cavity of the heating furnace 2 is 1600 ° C; the temperature detection device adopts double platinum rhodium type Thermocouples measure the temperature in the furnace cavity of the heating furnace 2 in real time; the quenching pool 8 is arranged below the heating furnace 2, and the bottom of the heating furnace 2 is separated from the quenching pool 8 by the heat insulation layer 6 , the water-coole...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, especially in that:

[0060] In this embodiment, a method for preparing a functionally graded material using an axial uniform magnetic field uses the same directional solidification device as in Embodiment 1. When preparing an Al-Cu alloy functionally graded material, the following steps are included:

[0061] a. Raw material preparation:

[0062] Select high-purity metal raw materials with a purity of 99.99%, prepare Al-40wt.% Cu alloys, and repeatedly smelt them in a vacuum suspension furnace to fully homogenize the Al-Cu alloy raw materials. The tube is subjected to negative pressure suction casting to obtain an Al-Cu alloy rod with uniform composition, and the obtained Al-Cu alloy rod is packaged in a corundum crucible for standby;

[0063] b. Directional solidification equipment installation:

[0064] Put the directional solidification device in the axial uniform magnetic field, the magnetic field strength ne...

Embodiment 3

[0081] This embodiment is basically the same as the previous embodiment, and the special features are:

[0082] In this embodiment, by controlling the strength of the magnetic field, the magnitude of the gradient distribution of the directionally solidified primary phase structure along the longitudinal direction of the prepared material is adjusted.

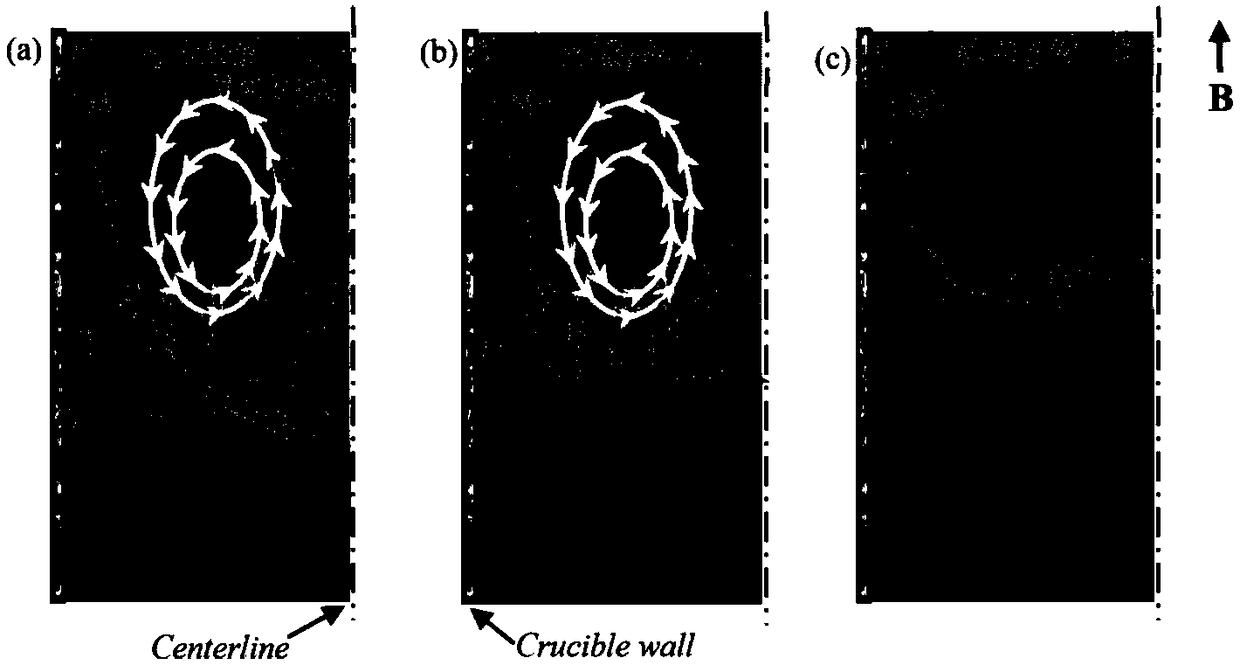

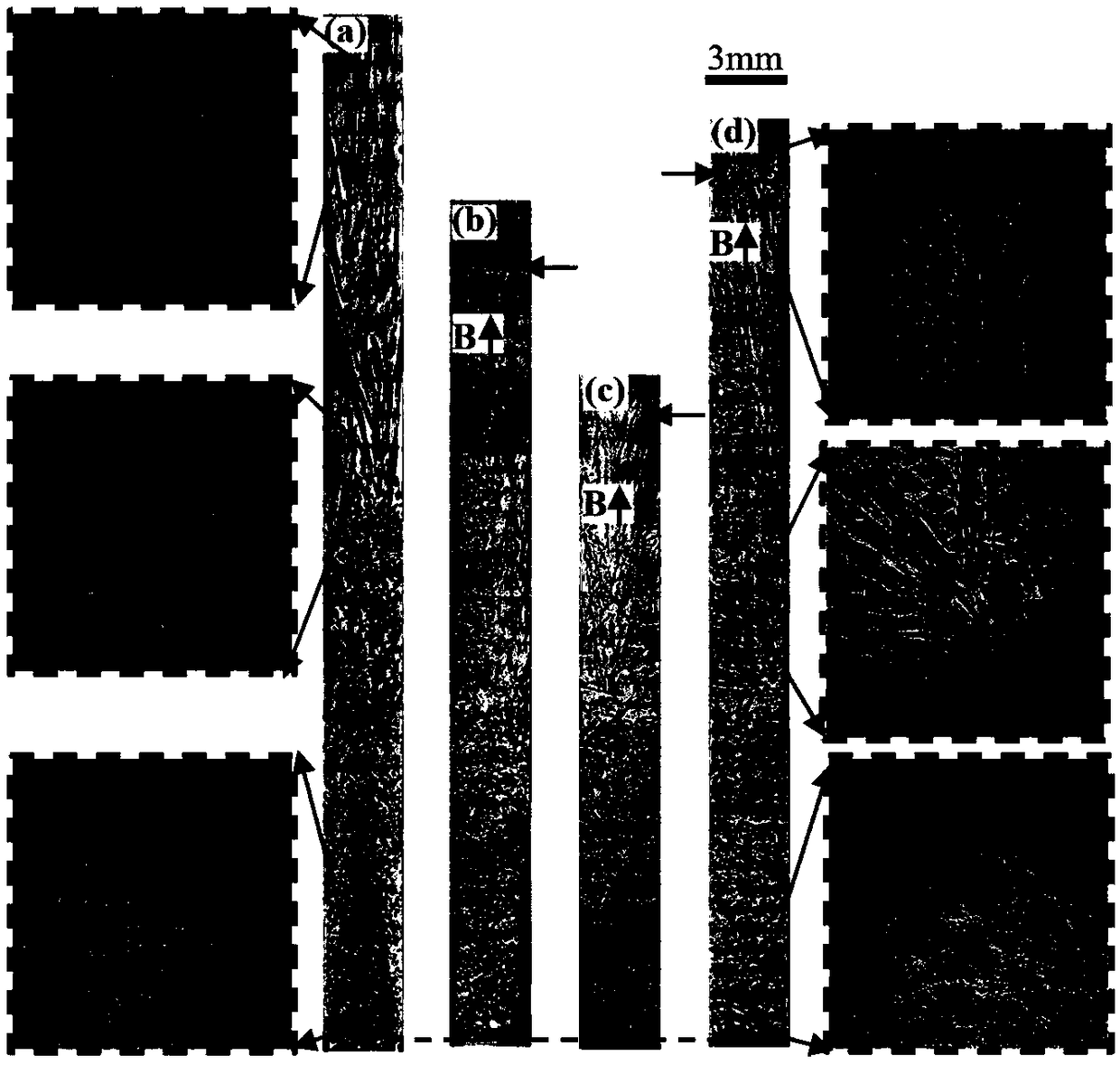

[0083] It can be seen from Examples 1 and 2 that the directional solidification samples obtained in Examples 1 and 2 were cut symmetrically along the longitudinal direction to obtain a longitudinal section sample for observing the tissue. After the sample was mounted, it was ground and polished for corrosion observation Microstructure. image 3 and Figure 4 The comparisons of the directional solidified structures of Example 1 and Example 2 respectively reflect the contrast of solidified structure morphology before and after applying an axial uniform magnetic field. In Figure b-0.5T, Figure c-1T and Figure d-3T, it can be seen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap