Mechanical arm zero force control experimental system facing direct demonstration

A zero-force control and robotic arm technology, applied in the field of robotic arm zero-force control experimental systems, can solve the problems of low flexibility of direct teaching, slow response speed, and low control accuracy, and improve real-time performance and teaching response. The effect of speed, control accuracy improvement, and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

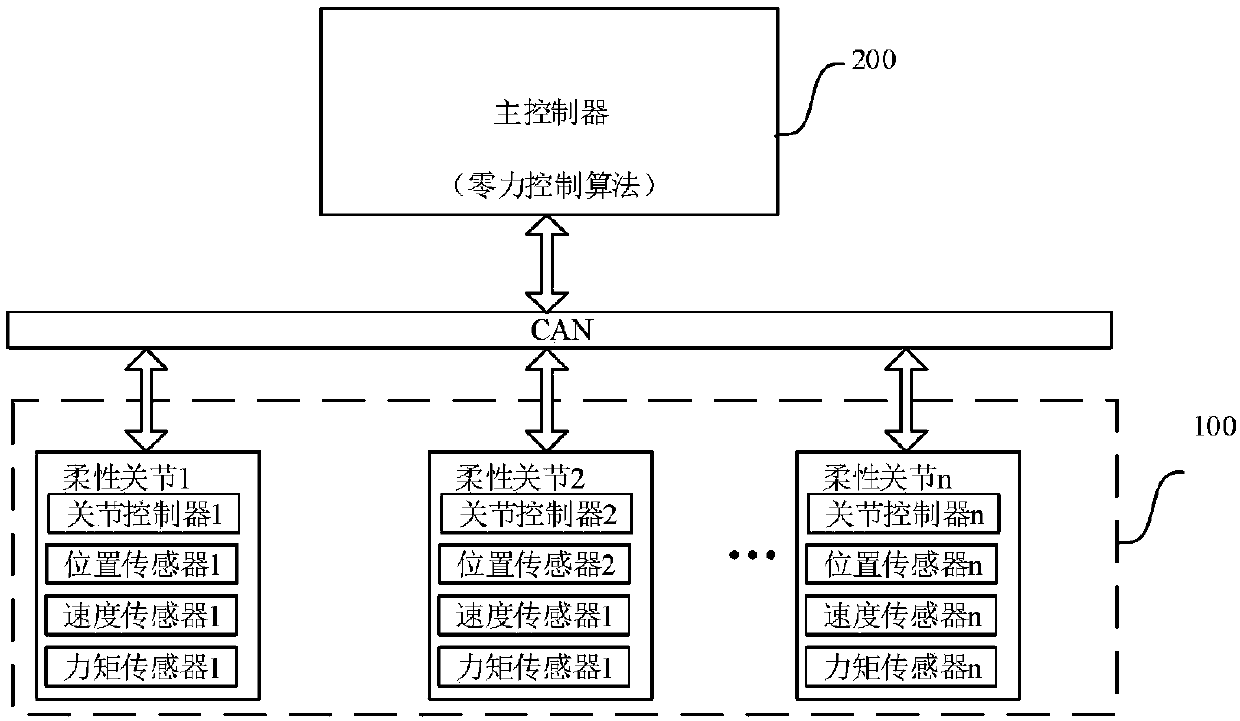

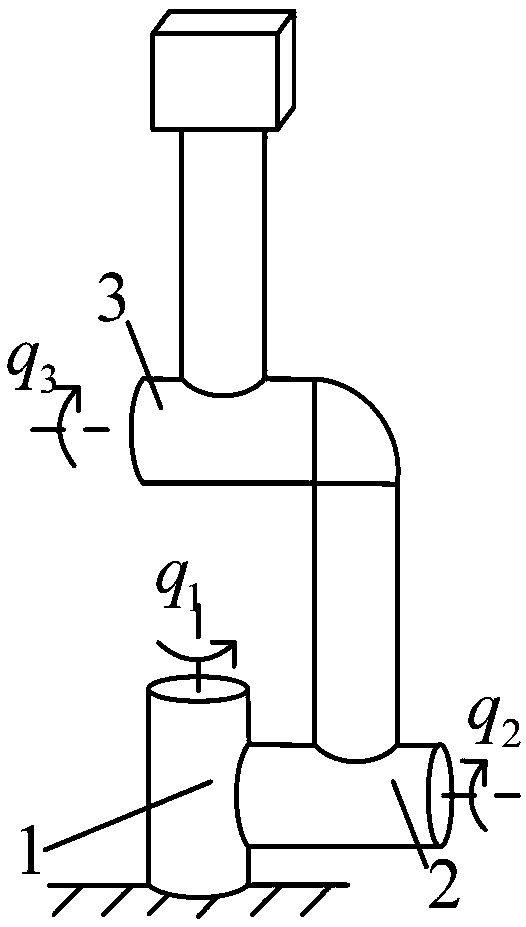

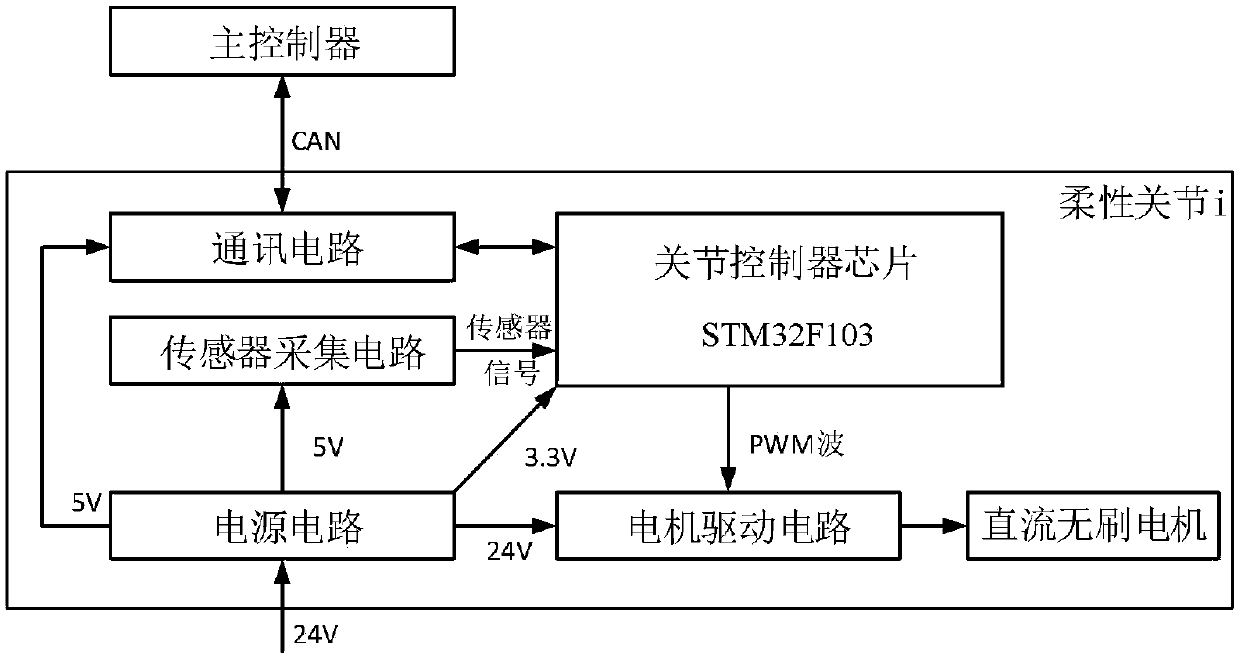

[0022] The specific embodiment of the present invention provides a zero-force control experimental system of a mechanical arm for direct teaching, refer to figure 1 , the system includes an n-degree-of-freedom mechanical arm 100 with n flexible joints and a main controller 200, each flexible joint of the mechanical arm 100 is equipped with a sensor acquisition circuit and a joint controller, each of the joint controllers is connected via a bus communication with the main controller; the sensor acquisition circuit includes a joint speed sensor, a joint position sensor and a joint torque sensor, which respectively collect the speed information, position information and torque information of the flexible joint and send them to the main controller through the main controller to perform zero-force control, obtain the compensation torque value of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com