Guide structure for propping block connecting rod

A guiding structure and connecting rod technology, applied in the field of injection molds, can solve the problems affecting the mold processing cycle, easy eccentricity of the ejector pin hole, complicated processing procedures, etc., and achieve the effect of reducing the mold processing cycle, improving the quality of injection molding products, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

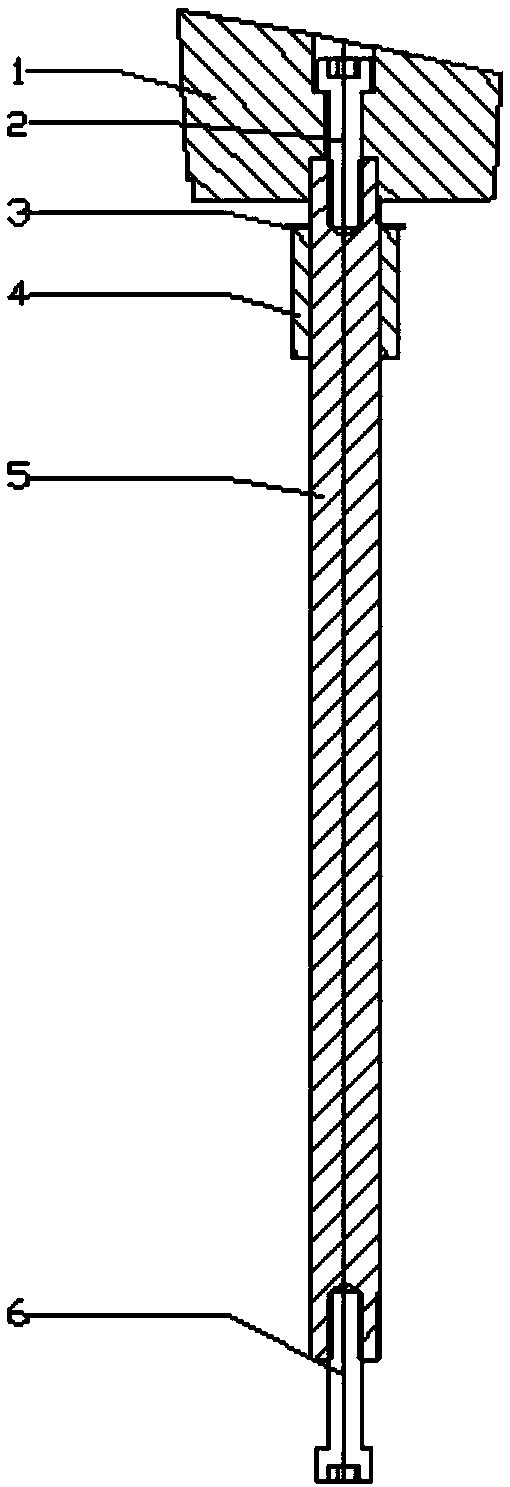

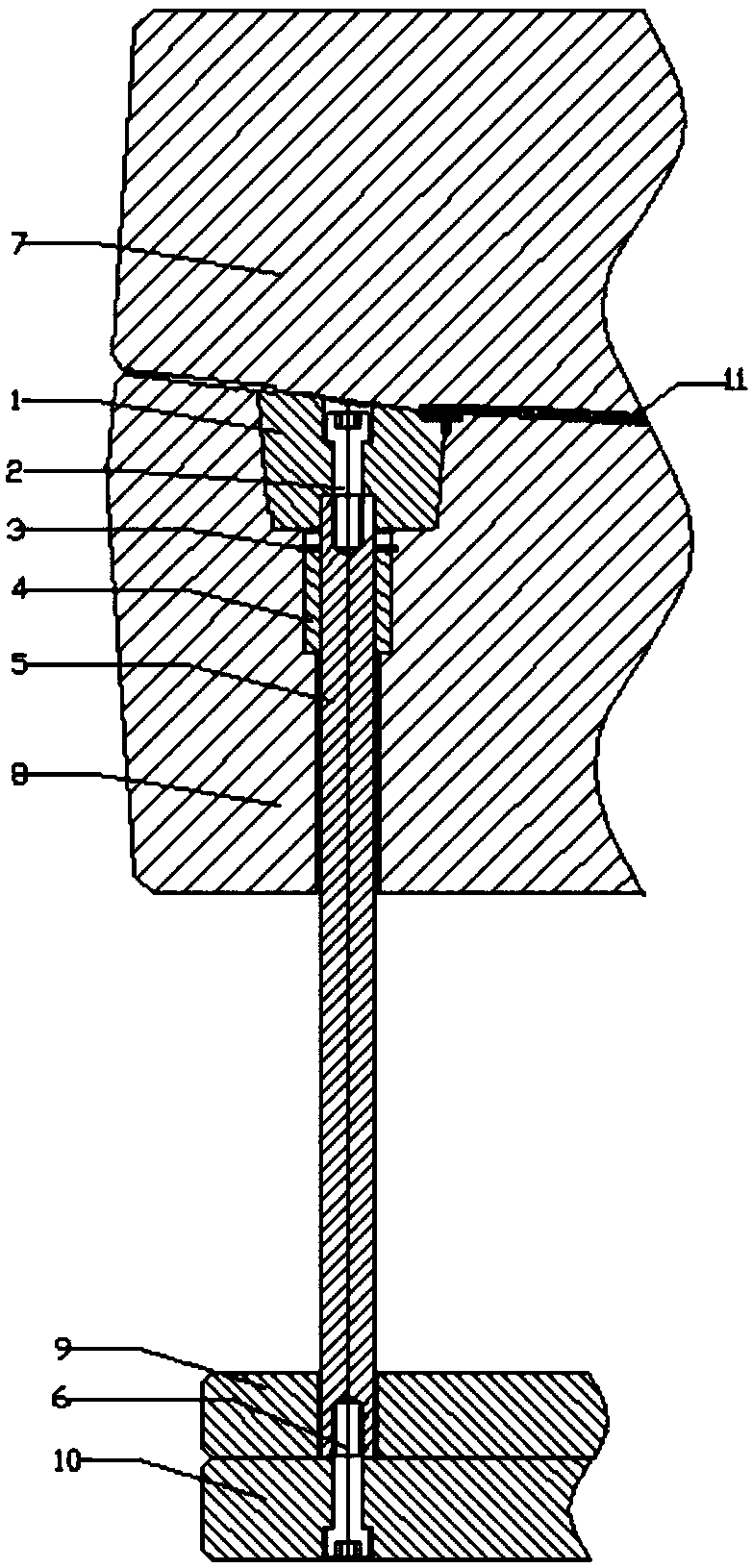

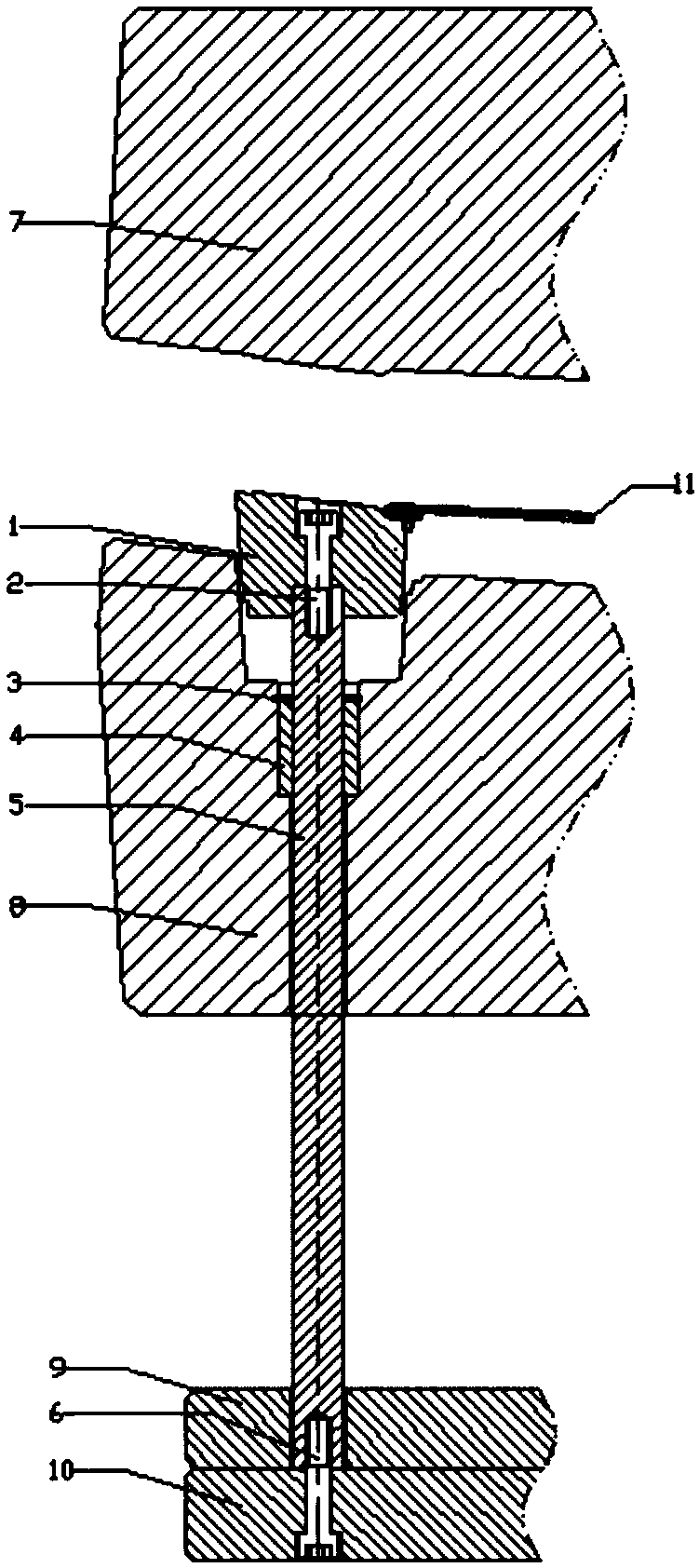

[0019] This embodiment proposes a guiding structure for the connecting rod of the jacking block, such as figure 1 As shown, it includes a jacking body 1, a first screw 2, a retaining spring 3, a guide sleeve 4, a push rod 5 and a second screw 6, and the head of the ejector rod 5 is equipped with a jacking body 1, through which the first screw 2 Fastening; the head of the ejector rod 5 is provided with a straight surface in the installation area of the ejector body 1; the front end of the ejector rod 5 is provided with a guide sleeve 4;

[0020] Such as figure 2 , 3 As shown, the ejector rod 5 is located in the movable mold core 8 and is kept out of the air. The tail of the ejector rod 5 cooperates with the ejector pin base plate 9 and the ejector pin panel 10 of the injection molding machine, and is fastened by the second screw 6. The tail of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com