Composite tube forming device

A pipe forming and steel-plastic composite technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of not being environmentally friendly, short lifespan, and not many

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

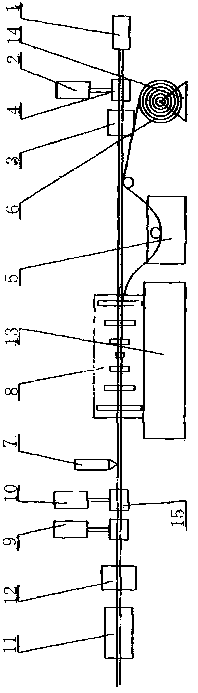

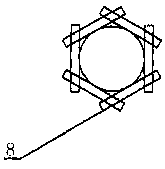

[0006] The present invention will be further described in conjunction with the accompanying drawings, the plastic pipe extruded by the inner layer thin-walled plastic pipe extruder (1) through the rubber material extruder (2) in the front is painted on the plastic pipe by the glue coating device. The outer circular surface of the plastic pipe is cooled by the cooling tank (3) in front to harden the plastic pipe and remove it from the steel strip (6) supported on the coil support (3) by cleaning and drying equipment (5). After derusting, degreasing, etc., it enters the steel pipe forming mold combination device together. The steel strip is gradually rolled and squeezed by the roller rolling mold to form a steel pipe and tightly wrapped on the outer circle of the plastic pipe, and then the lap welded by the rolling welding machine (7) Live, the rubber material extruded by the outer layer plastic material extruder (10) is applied to the outer surface of the steel pipe through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com