Centralized waste collection system for corrugated board production line

A waste collection and corrugated cardboard technology, applied in presses, machining/deformation, manufacturing tools, etc., can solve the problems of affecting the production site environment, easy to be lifted by the wind, etc., so as not to fly around and reduce the generation of scraps , The effect of paper stack compaction and completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

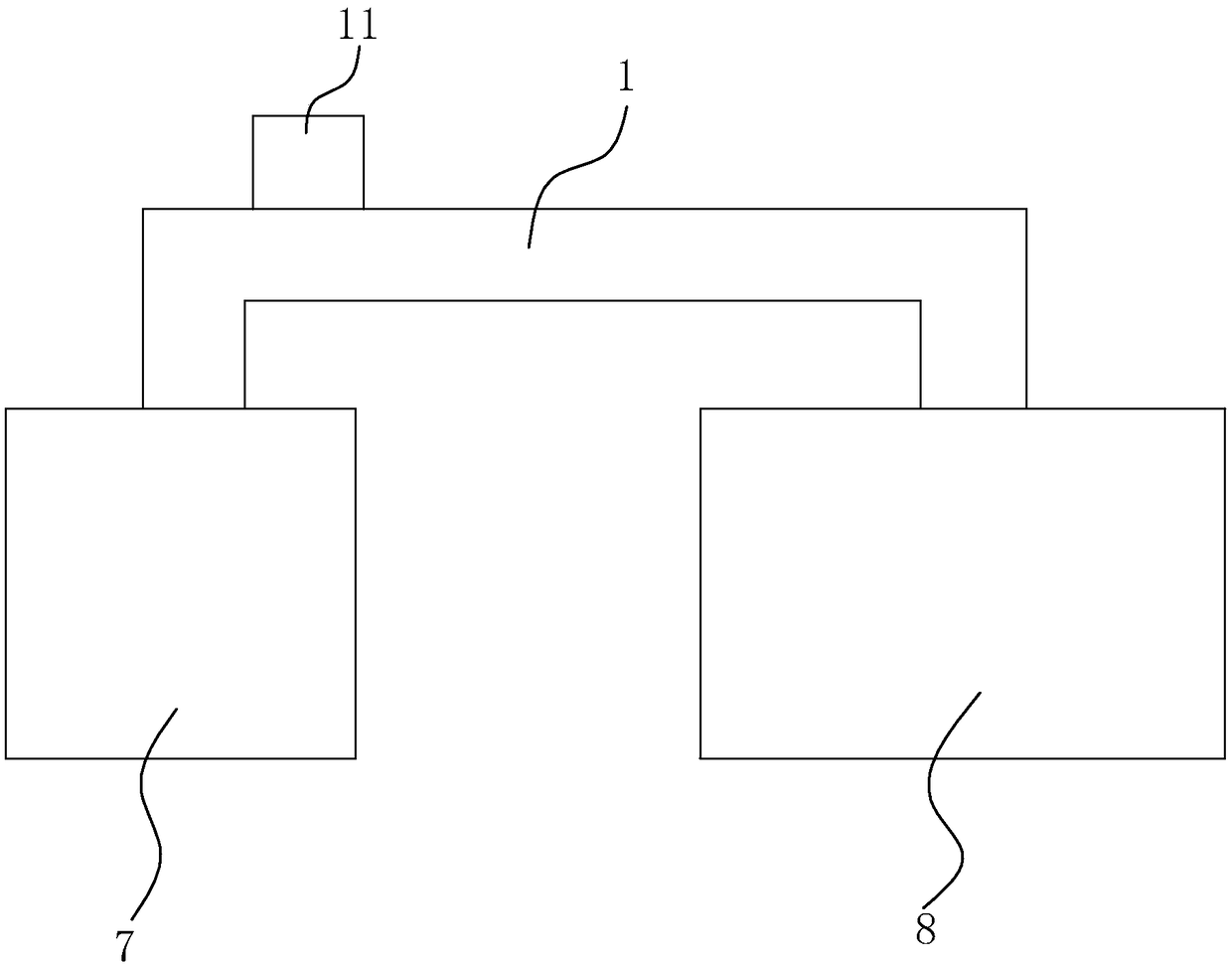

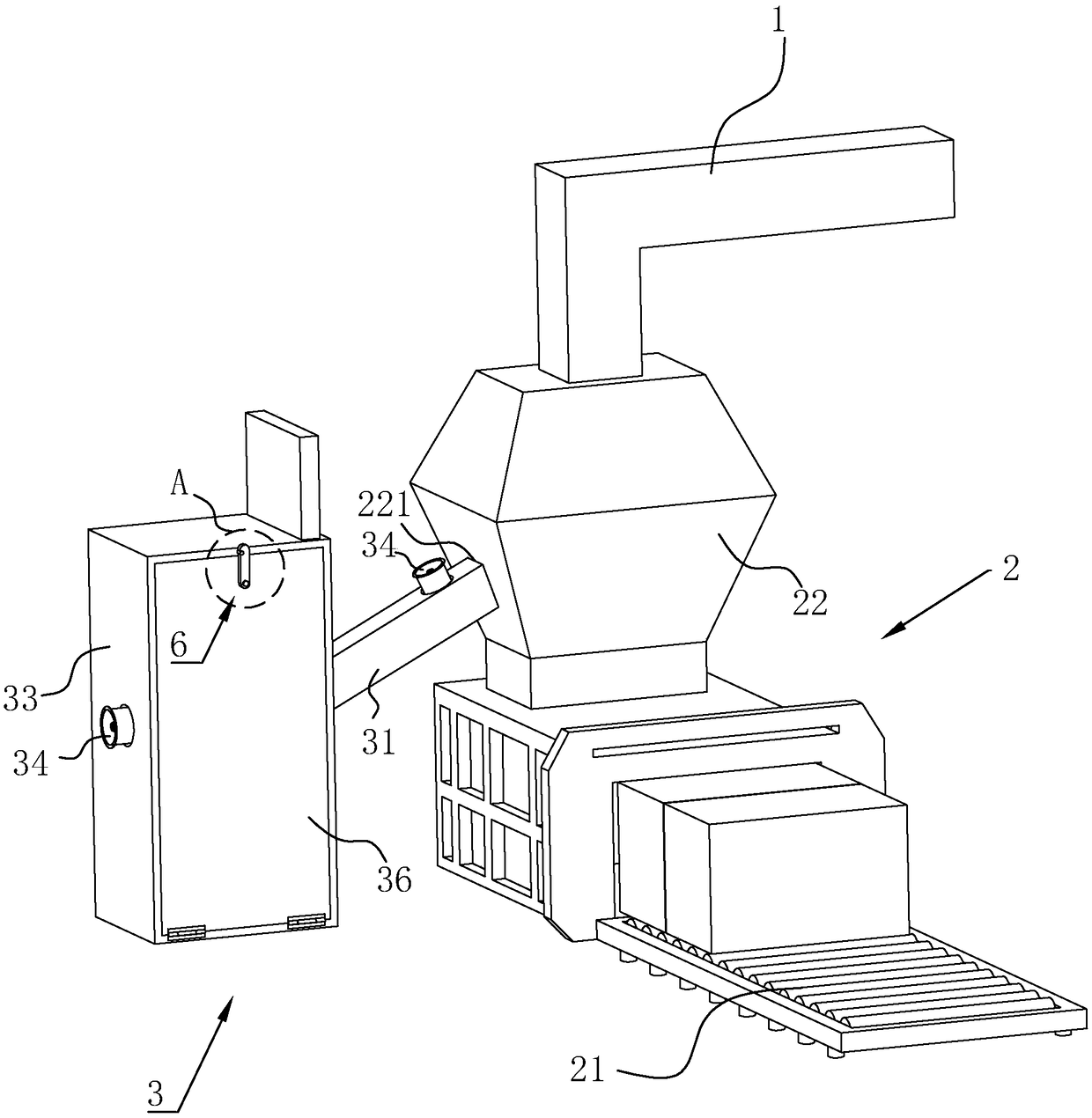

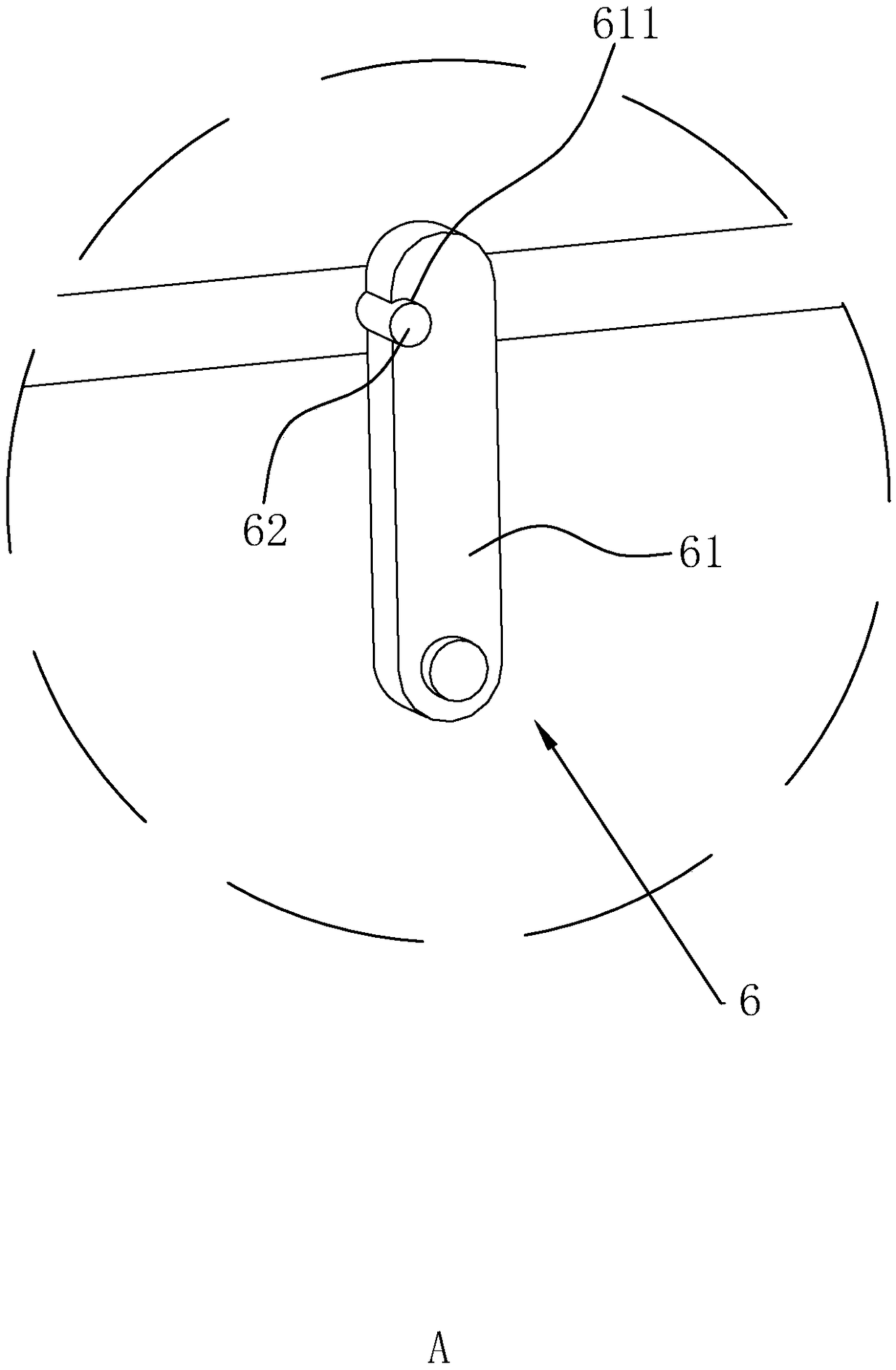

[0039] A centralized waste collection system for a corrugated cardboard production line, such as figure 1 and figure 2 As shown, it includes a feeding pipeline 1 connected to a paper shredder. The paper shredder is located in the workshop 8 of the corrugated cardboard production line. The cardboard scraps are conveyed to the hydraulic baler 2, and then bundled into stacks after being formed by the hydraulic baler 2. The cardboard scraps are directly formed by the hydraulic baler 2, which reduces the generation of scattered scraps and improves the environmental quality. And the hydraulic baler 2 is located in the waste material collection workshop 7, which is isolated from the corrugated paper production line workshop 8, so that the corrugated paper production line workshop 8 is kept clean. The outlet of the hydraulic baler 2 is equipped with a blanking track 21. Driven by the hydraulic baler 2, the stacks of paper are arranged on the blanking track 21 in an orderly manner, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com