Novel paper twisting wheel

A paper pickup roller, a new type of technology, applied in the field of printers, can solve the problems of easy wear on the surface, the decrease of the friction force of the paper pickup roller on the paper, and the failure of the printer to load paper normally, so as to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

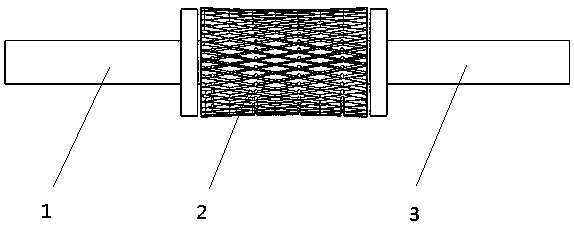

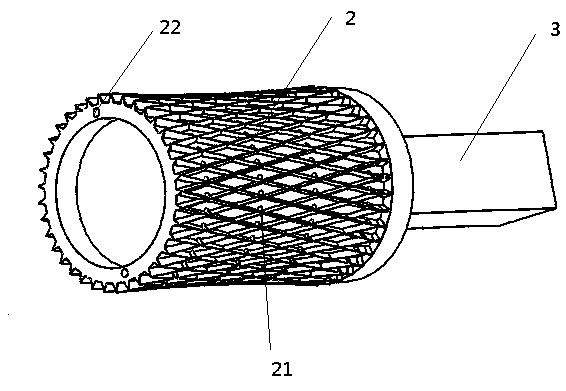

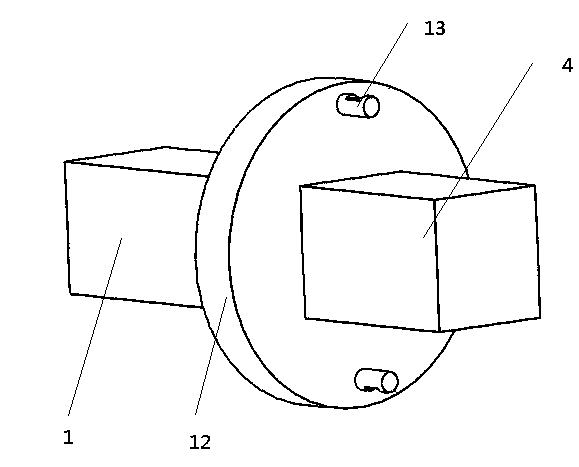

[0009] Refer to attached figure 1 , attached figure 2 And attached image 3 , a new pickup roller, comprising a left driving rod 1, a pickup roller 2, a right driving rod 3 and a foreign matter recovery rod 4. The paper pickup roller 2 is a hollow cylindrical structure, the right end is fixed on the right drive rod 3, and the left side has two buckle holes 22 up and down. to a circular hole 21 of 3 mm; the left drive rod 1 is made of metal, and the right end is a circular baffle 12 with the same diameter as the outer diameter of the pickup roller 2, and the baffle 12 is in phase with the buckle hole 22 of the pickup roller 2 There are two protruding buckles 13 at the corresponding positions, and the foreign body recovery rod 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com