Space inhaul cable anti-collision vibration-isolation type universal connection device and manufacturing and mounting methods thereof

A universal connection and anti-collision technology, which is applied in special structures, bridge parts, bridges, etc., can solve the problems that the cable cannot be realized, the surface of the cable body is damaged, and the aesthetics of the cable is affected, so as to avoid easy bending damage , The production and installation method is simple, and the effect of promoting the value of use is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A space cable anti-collision vibration isolation universal connection device:

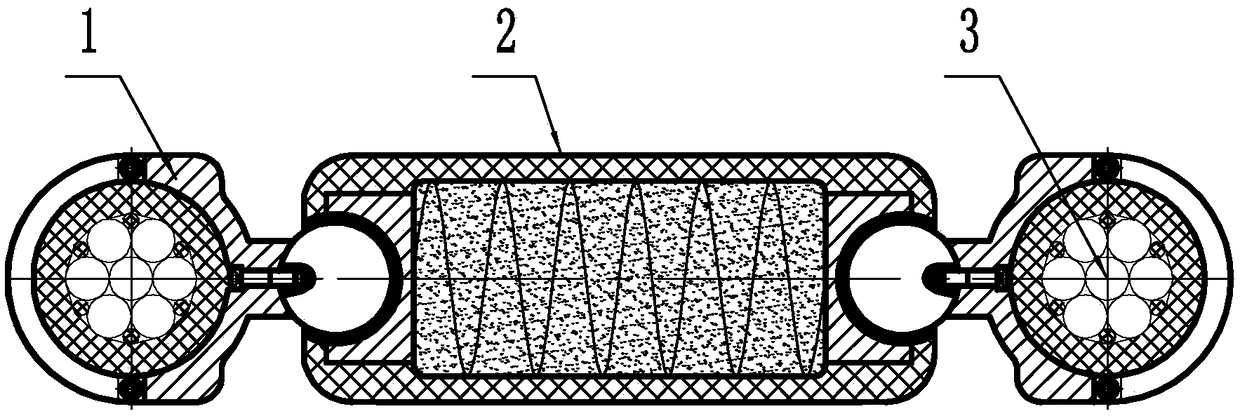

[0050] Such as figure 1 As shown, the space cable anti-collision and vibration isolation universal connection device includes a semicircular hoop assembly 1 and a buffer type universal rotary connector assembly 2, and 3 in the figure is a PE cable body;

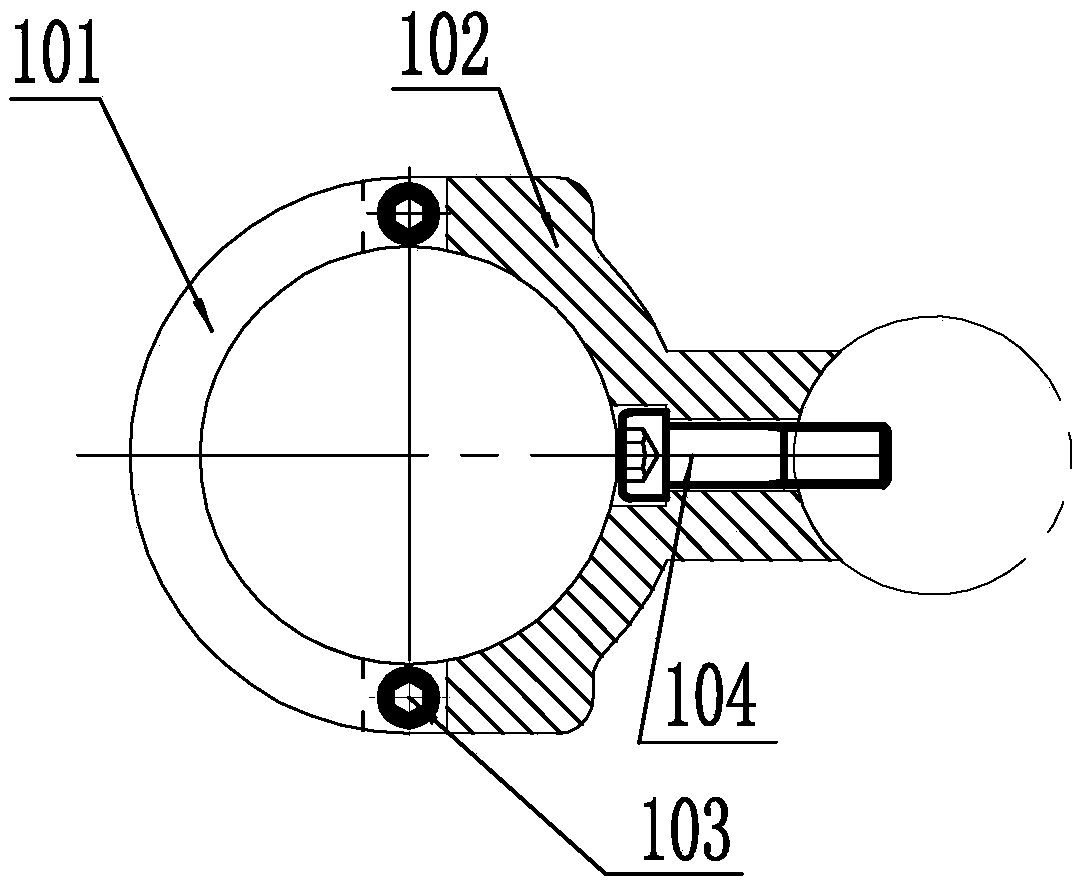

[0051] Such as figure 2 As shown, the semicircular cable clamp assembly includes two semicircular cable clamps A-type semicircular cable clamp 101 and B-type semicircular cable clamp 102 (see Figure 4-Figure 7 ), the connecting bolt I103 tightly connects the two semicircular hoops and fixes and connects the PE cable body 3;

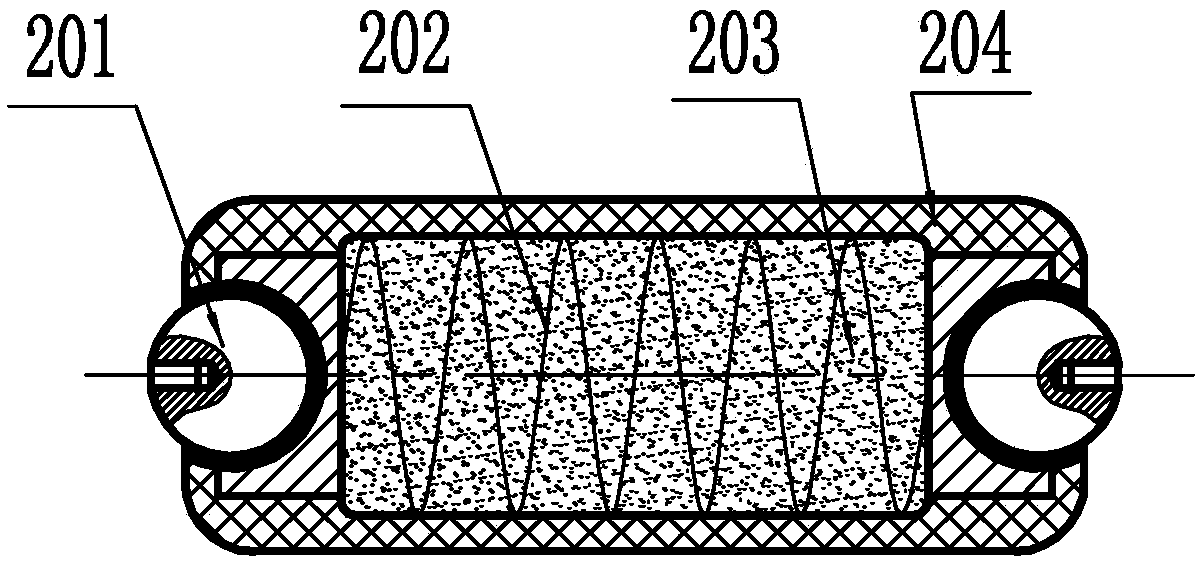

[0052] Such as image 3 As shown, the buffered universal rotary connector assembly 2 includes a high-damping elastic body 204, two universal ball bearings 201 located at both ends of the high-damping elastic body 204, a compression spring 202 located in the high-damping elastic body 204 and The elastic sealing bod...

Embodiment 2

[0056] A method for manufacturing and installing a space cable anti-collision and vibration-isolation universal connection device, which is a method for manufacturing and installing the space cable anti-collision and vibration-isolation universal connection device described in Embodiment 1, and it includes the following steps:

[0057] A. Make two semicircular hoops:

[0058] According to the conventional method, the cable clamps of steel structural parts are made by model casting or welding, or the A-type semi-circular cable clamps 101 and B-type semi-circular cable clamps 102 are produced by non-metallic elastic material components through extrusion molding, and the B-type semi-circular cable clamps There is a concave platform (1021) connected with the spherical surface of the universal ball bearing on the side of 102;

[0059] B. Making buffered universal rotary connector assembly 2:

[0060] B1: Connect the bases of the two universal ball bearings 201 with the compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com