Container house box bottom

A container and house technology, applied in the direction of construction, building structure, etc., can solve the problems of unguaranteed welding quality, high transportation cost, inconvenient transportation, etc., and achieve the effects of saving transportation costs, avoiding safety hazards, and simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The substantive features and advantages of the present invention will be further described below in conjunction with examples, but the present invention is not limited to the listed embodiments.

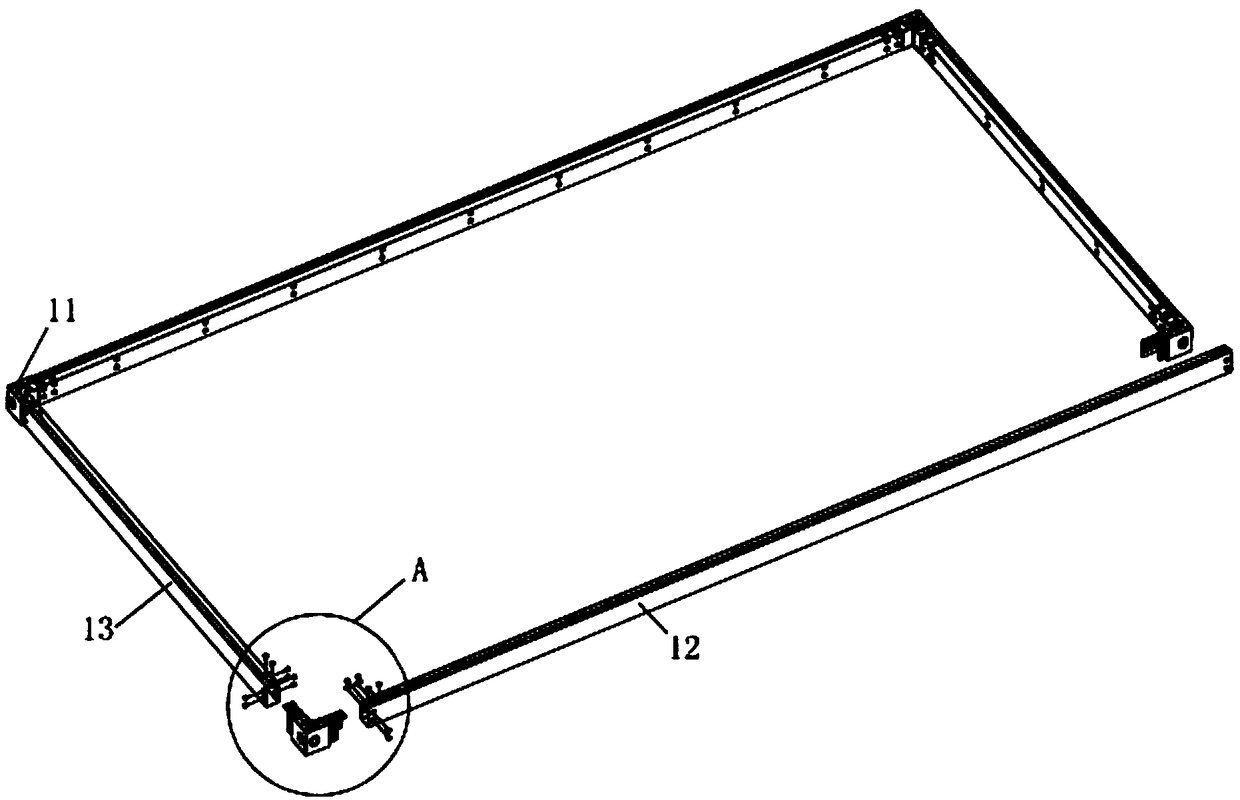

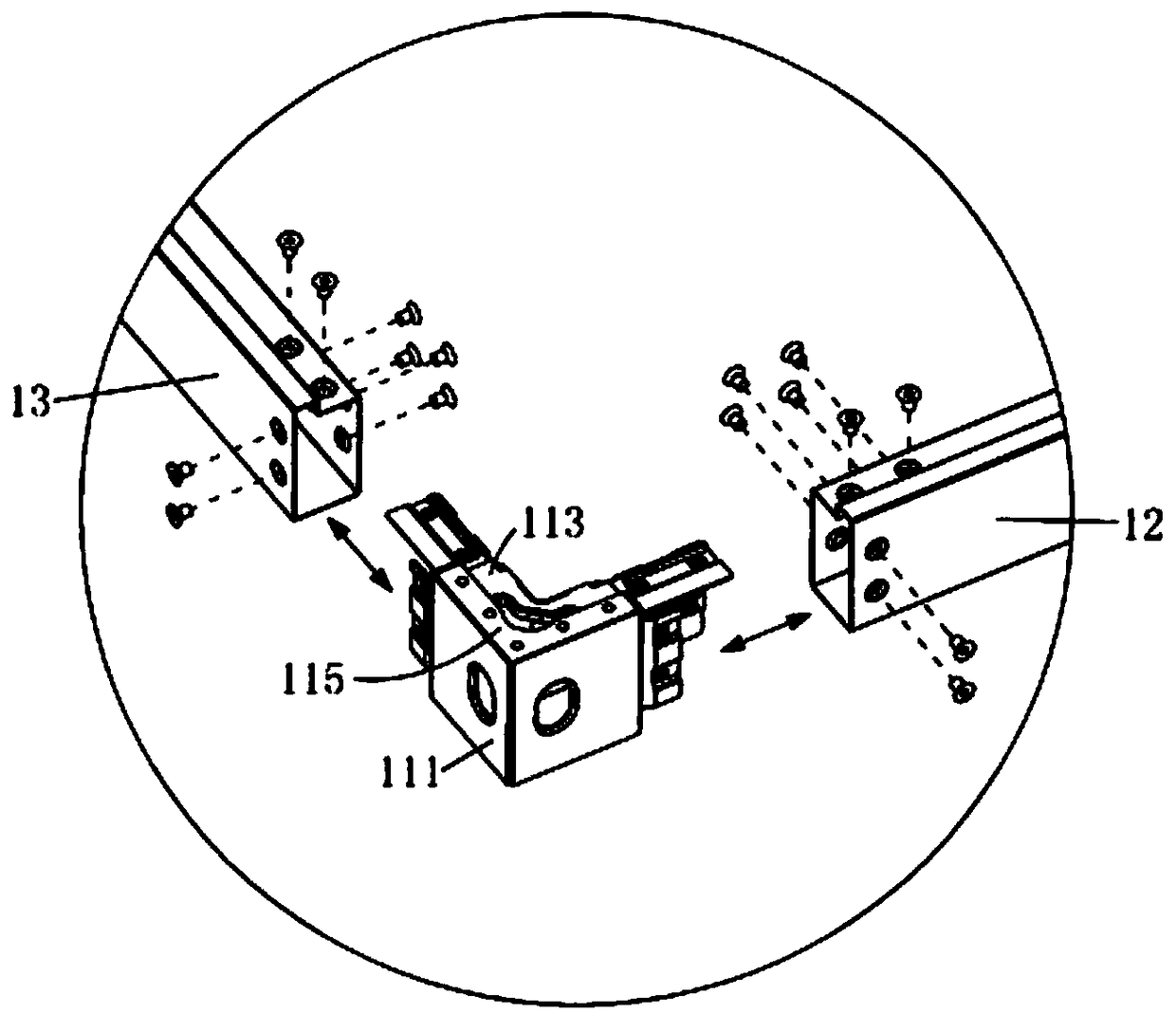

[0037] like Figure 1 to Figure 20 As shown, a container bottom includes an outer bottom frame 1, a secondary beam 2, a bottom girder 3, a bottom sealing girder 4, a bottom sealing plate 5 and a floor cushion plate 6, and the outer bottom frame 1 is composed of a The parallel long bottom beams 12 and a pair of parallel short bottom beams 13 enclose a rectangular frame with a rectangular outline and the four corners are connected by corner fittings 11, and the two ends of the corner fittings 11 are fitted and inserted into the corresponding long bottom beams 12 respectively. And in the cavity at the end of the short bottom beam 13 and fixed by bolts.

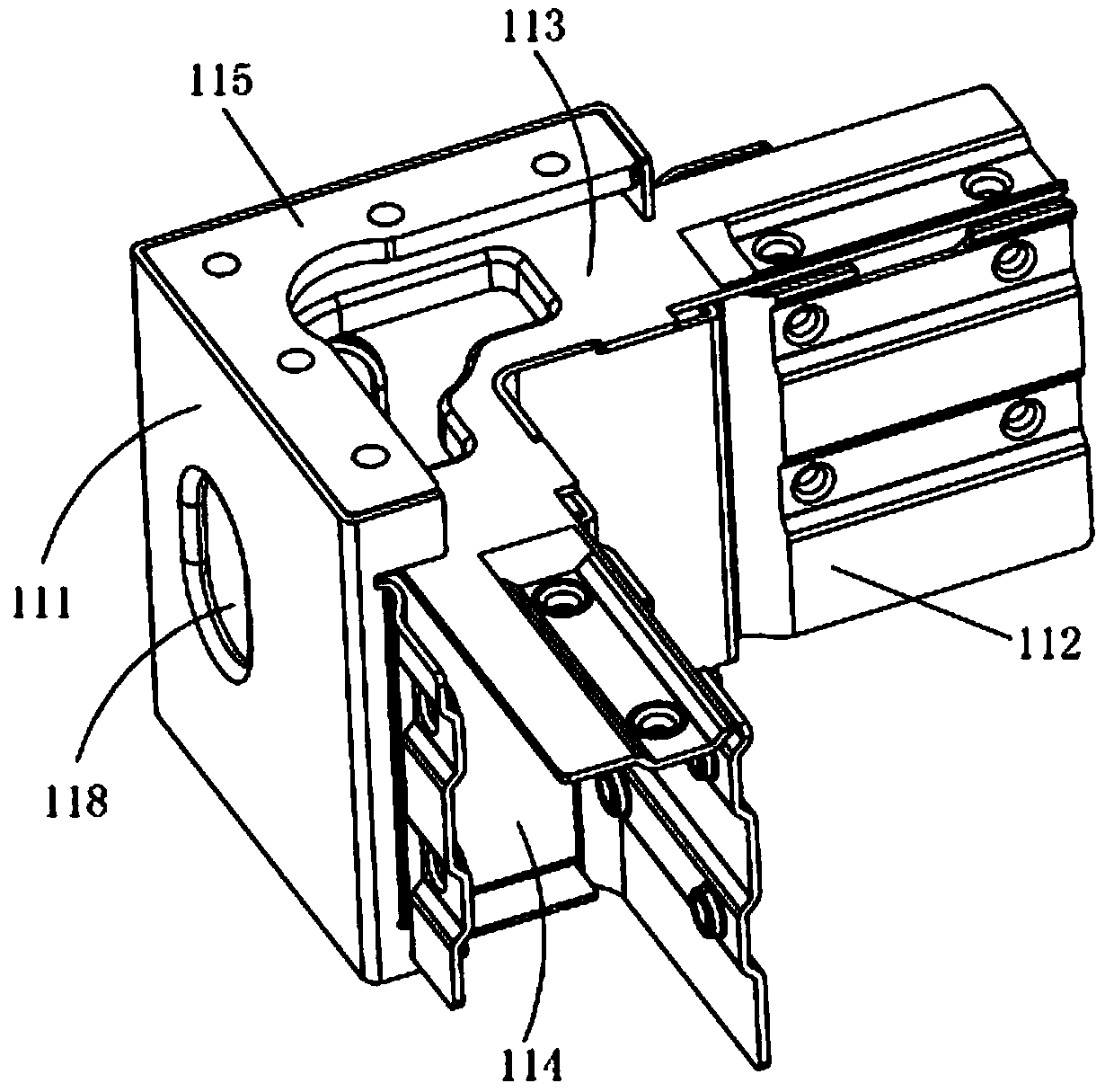

[0038] The corner piece 11 includes an outer plate 111 bent at a right angle, a large L plate 113 welded to the upper height o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com