Profile window with excellent sealing performance

A technology with excellent sealing performance, applied in the field of doors and windows, can solve the problems of no EPDM rubber solid anti-collision strip, no anti-collision plastic parts, can not play a sealing role, etc., to achieve assembly gap and unevenness The effect of reducing the degree of water resistance, improving the waterproofness, and absorbing the kinetic energy of the collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

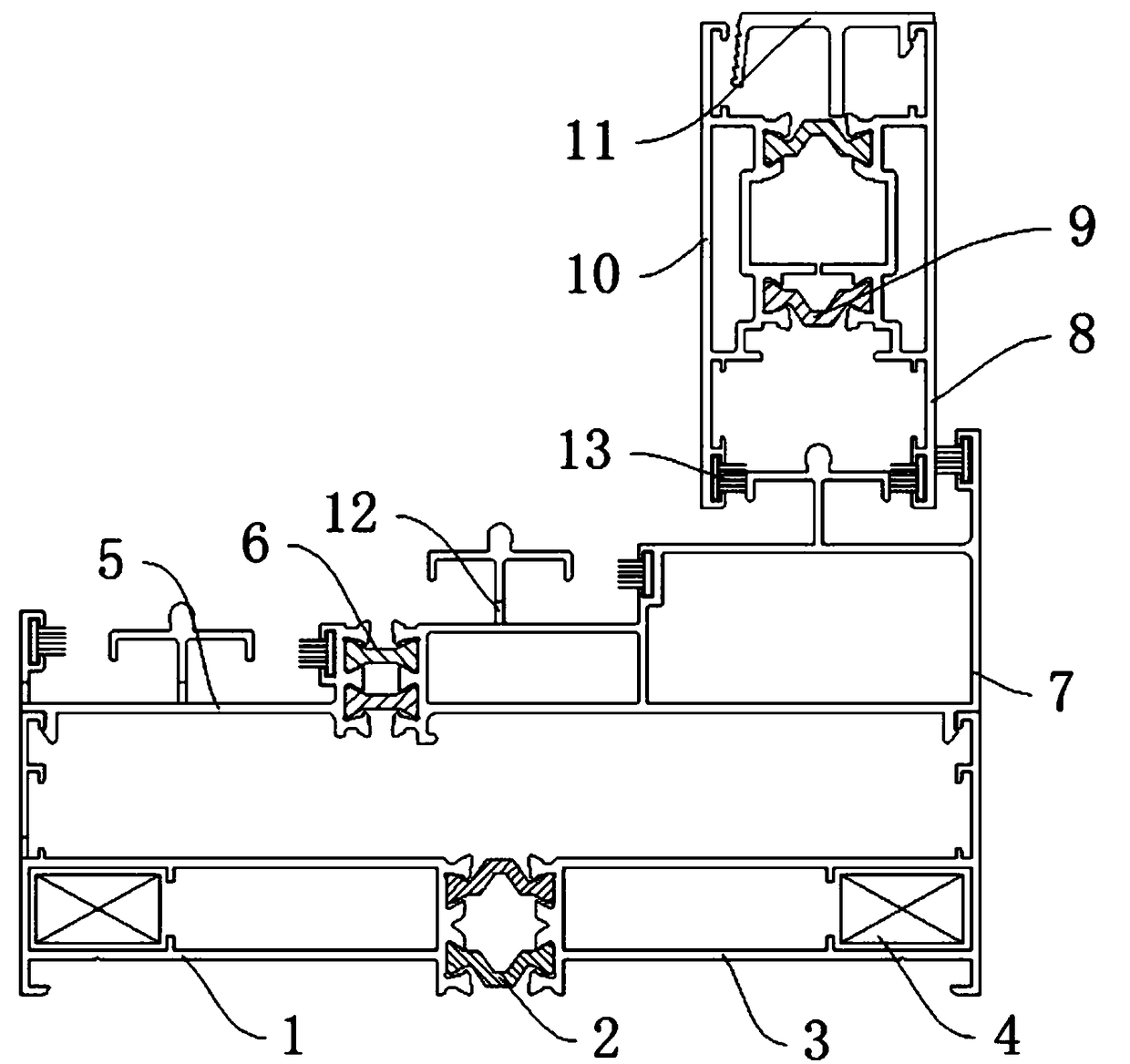

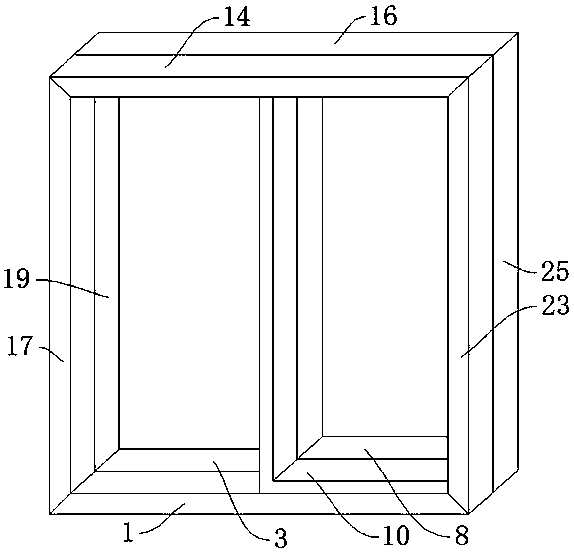

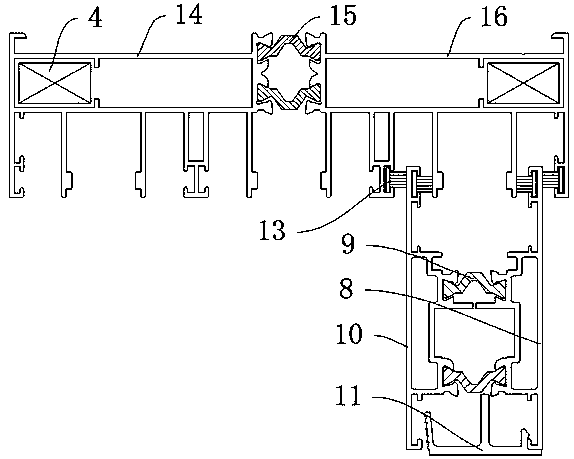

[0050] like Figure 1-Figure 9 As shown, a profile window with excellent sealing performance includes a first lower frame 1, a first upper frame 14, a first left seal 17, and a first right seal 23, and a first lower heat insulation is arranged behind the first lower frame 1. Strip 2, connecting the first lower frame 1 and the second lower frame 3, the second lower frame 3 is arranged behind the first lower heat insulation strip 2, supports the second lower rail 7, and the second lower frame 3 is provided with movable corner codes 4. To connect the seam, the first lower rail 5 is arranged on the top of the first lower frame 1, and the first lower rail 5 is provided with drainage holes 12, which are drainage channels, and the second lower heat insulation is arranged behind the first lower rail 5. Bar 6, connecting the first lower rail 5 and the second lower rail 7, the second lower rail 7 is arranged behind the second lower heat insulation strip 6, supporting the glass fan 8, an...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is:

[0053] The gauze plastic cover 11 is made of soft plastic material, and the gauze plastic cover 11 is connected with the glass sash 8 and the door and window sash 10 using buckles respectively. The soft plastic material is convenient for the gauze plastic cover 11 to bend and compress the metal gauze, and the buckle connection is convenient. Dismount gauze plastic cover 11 and replace.

[0054] Working principle: snap the first lower heat insulation strip 2 between the first lower frame 1 and the second lower frame 3, nail the first lower frame 1 and the second lower frame 3 to the bottom of the window, and insulate the second lower frame The strip 6 is inserted between the first lower rail 5 and the second lower rail 7, the first lower rail 5 is inserted into the first lower frame 1, the second lower rail 7 is inserted into the second lower frame 3, and the movable corner code is used to 4 Connect the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com