Method of tunnel rockburst protection construction using steel rope flexible net

A flexible net and rockburst technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as poor protection performance, increase deformation and impact time, improve the form of force, and shorten the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0038] A method for tunnel rockburst protection construction using a steel rope flexible net, in which the parallel construction of excavation operation, net hanging operation and concrete spraying operation is carried out on the excavation operation surface, net hanging operation surface and concrete spraying operation surface respectively in the tunnel , The protective net selected for the net hanging operation is a kind of flexible protective net against tunnel rockburst. When hanging the net, according to the rockburst level, choose to hang a single-layer net or hang a double-layer net.

[0039] This method is suitable for rocky underground engineering excavated by the drilling and blasting method, fully considering the particularity of rockburst protection in underground engineering engineering, and the concept of combining the construction of the protective net with the initial support construction of the tunnel. Simultaneous excavation and concrete spraying operations ca...

specific Embodiment 2

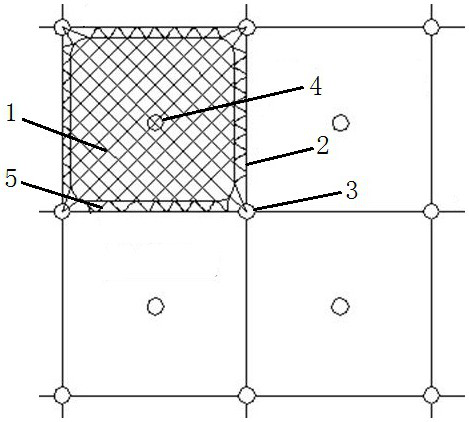

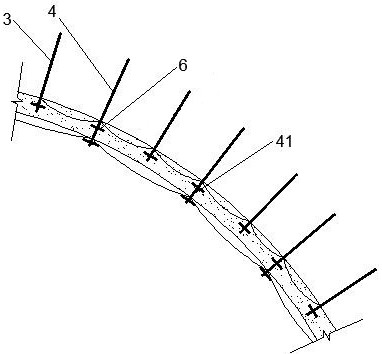

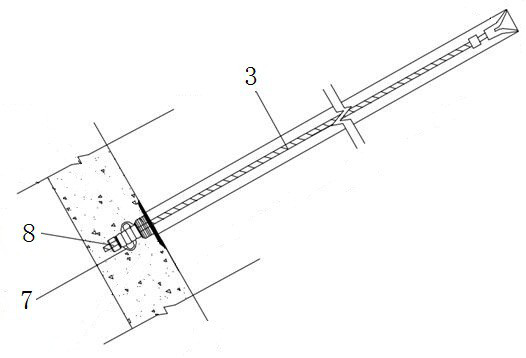

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, this embodiment is based on the specific embodiment 1 to further illustrate the tunnel rockburst flexible protective net. Type anchor 3 and center expansion shell anchor 4, the anchor head end of positioning expansion shell anchor 3 is inserted in the tunnel rock face, and adjacent positioning expansion shell anchors 3 are connected by support rope 2, The support rope 2 and the positioning expansion shell anchor 3 together form a support net. The steel wire rope net 1 is arranged in the grid of the support net. The steel wire rope net 1 and the support rope 2 of the support net are connected by suture rope 5. The anchor rod 4 is arranged in the middle of the wire rope net 1, the anchor head end of the central expansion shell anchor 4 is inserted in the rock face of the tunnel, and the end of the central expansion shell anchor 4 is provided with a fixed plate 6, and the fixed plate 6 The rear is also provi...

specific Embodiment 3

[0044] This embodiment is to further illustrate the steps of the net hanging operation on the basis of specific embodiment 1. The steps of the net hanging operation are as follows: a, cleaning up dangerous rocks; b, drilling, installing and positioning expansion shell type anchors Rod 3 and center expansion shell anchor 4; c. Install the rotating collar 7 and fixed nut 8 to the tail of the positioning expansion shell anchor 3 in sequence, and connect the two ends of the support rope 2 with the adjacent positioning expansion shells respectively. Connect the rotating collar 7 on the type anchor rod 3 to complete the horizontal arrangement and longitudinal arrangement of the support rope 2, and then pre-tighten the support rope 2 to form a support net; d, use the suture rope 5 to hang the steel wire rope net 1 on the support net In the grid; e, install the fixed plate 6 to the tail of the center expansion shell bolt 4, so that the steel wire rope net 1 fits the rock surface; f, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com