A new construction method for flue gas pipeline

A pipeline construction and flue gas technology, which is applied in the direction of pipeline protection, pipeline laying and maintenance, pipeline damage/wear prevention, etc., can solve the problems such as the easy occurrence of wrong edges in the welding joint group, and achieve easy control of construction quality, overcome ovality, The effect of shortening the construction time on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A novel flue gas pipeline construction method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

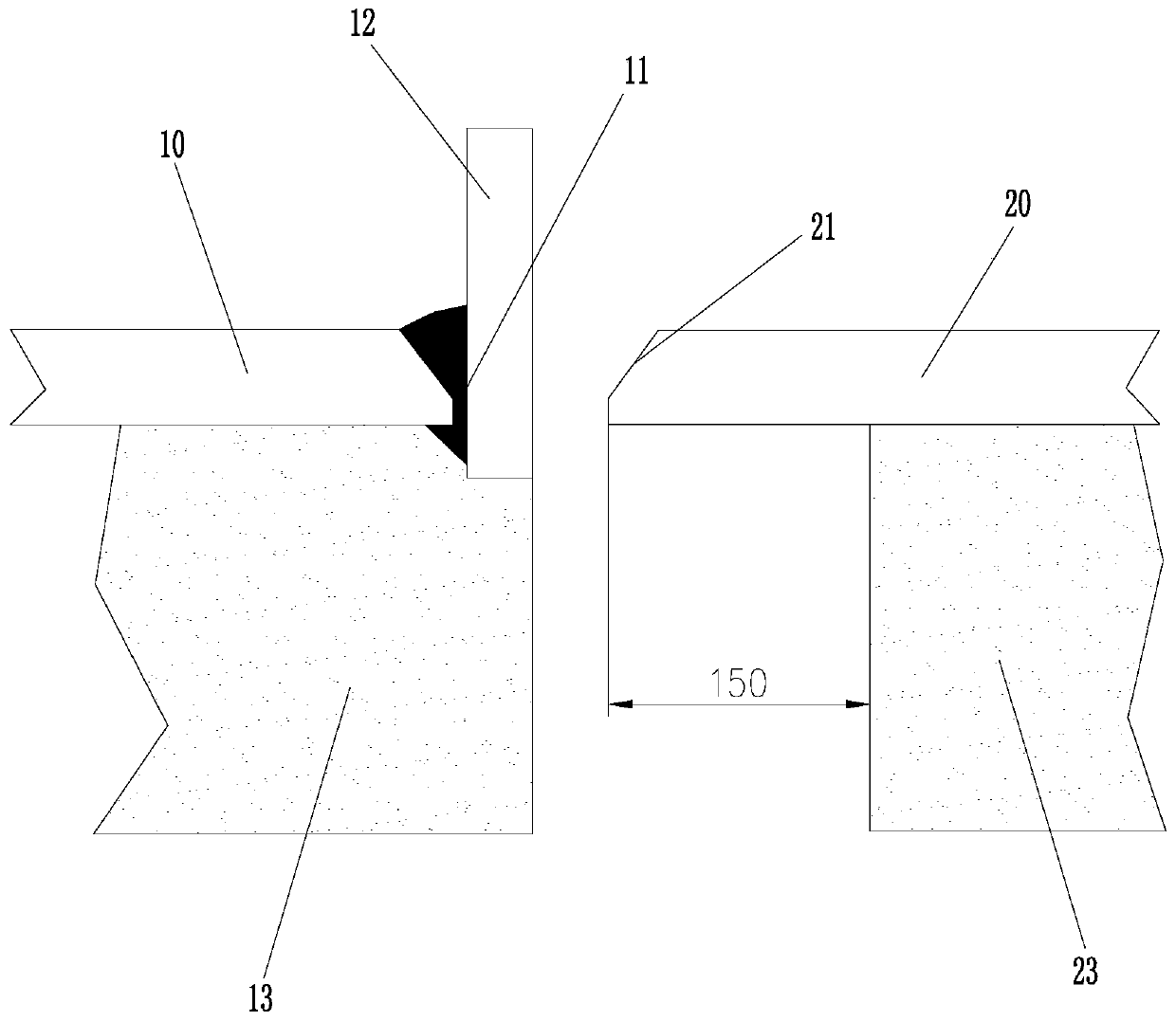

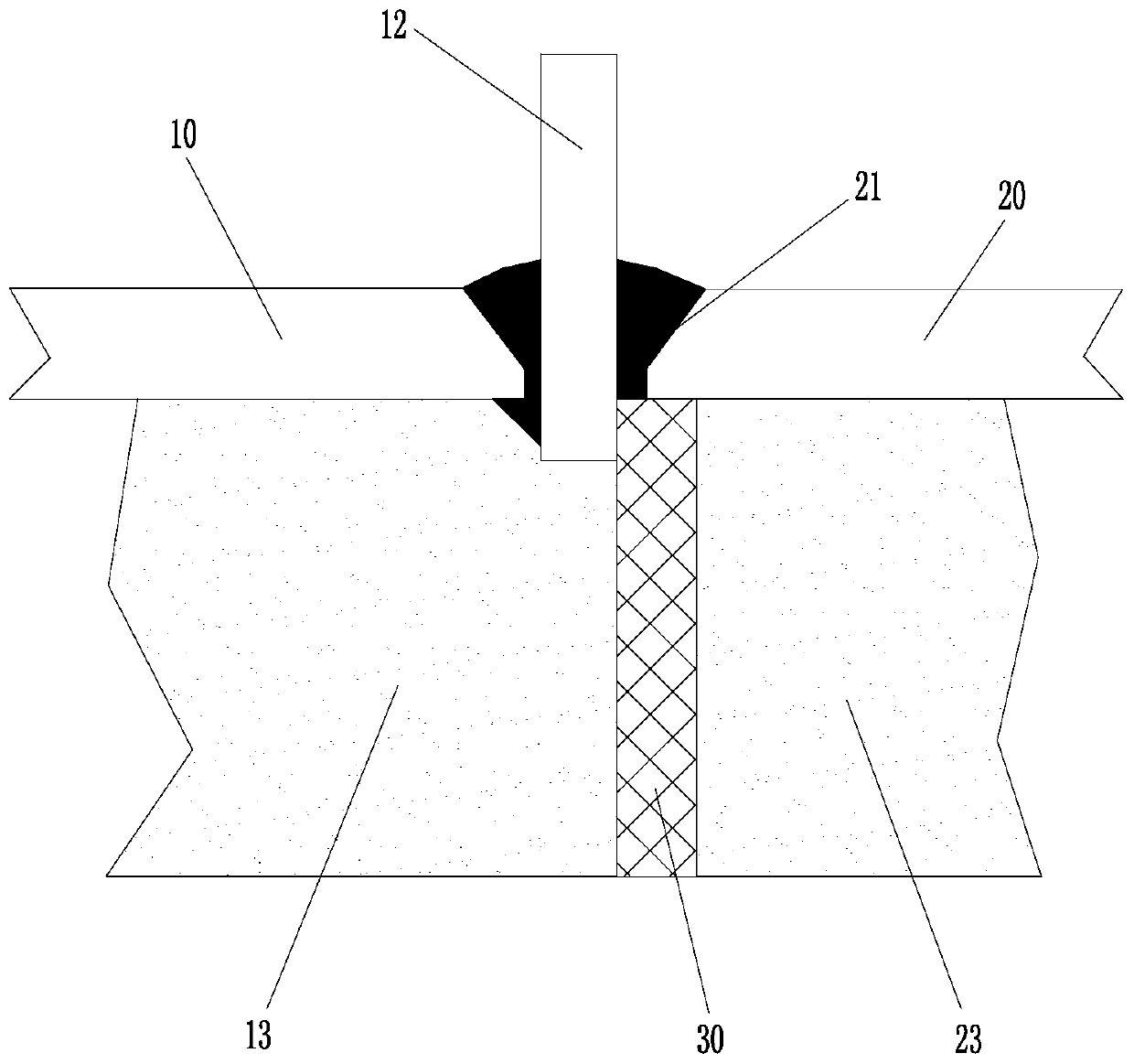

[0026] Such as figure 1 and figure 2 As shown, in this embodiment, a novel flue gas pipeline construction method of the present invention includes the following steps:

[0027] 1) Prefabricate the pre-installed flue gas pipe in sections in the prefabrication plant to form several pipe sections 10, 20;

[0028] 2) An annular plate 12 is welded on the edge of the end of one of the adjacent pipe sections 10, and the inner and outer welds of the annular plate 12 form a section 11 to ensure that the annular plate 12 has sufficient strength after welding. The annular plate 12 is 20-30mm Made of thick steel plate;

[0029] 3) Lining pouring construction is carried out to each pipe section 10, 20 to form inner lining layers 13, 23;

[0030] 4) Lift the pipe sections 10 and 20 in step 3) at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com