Jig frame intelligent layout method for ship sectional construction and computer storage medium

A technology of segmented construction and layout method, which is applied in the direction of ship construction, slipway, dry dock, etc., can solve the problems of irrationality and low intelligence, improve utilization rate, intelligent and precise layout, and avoid missing areas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

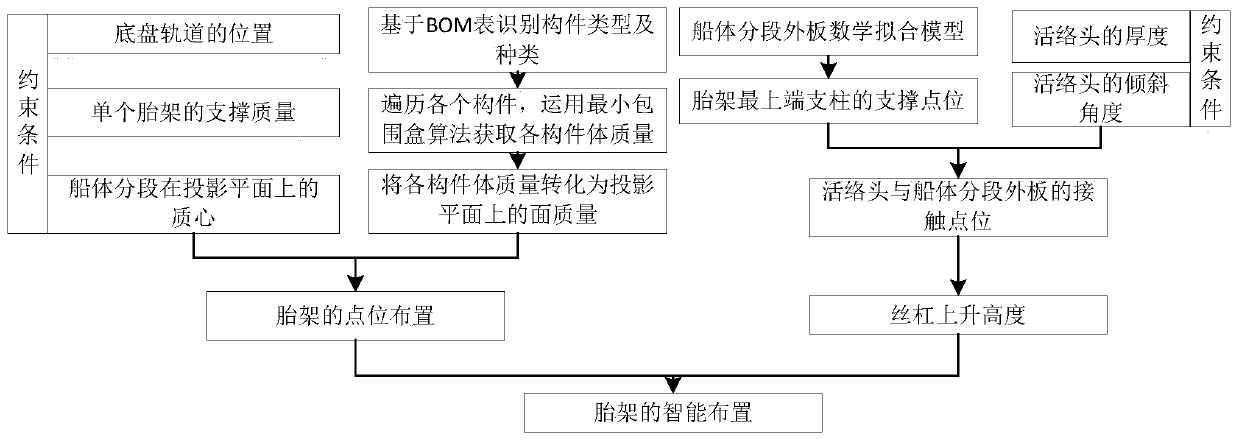

[0033] The present invention maps the three-dimensional model to the plane to determine the mass distribution on the plane, based on the mass distribution of the components on the plane and the slope of the hull section and other related constraints, determines the number of tire frames required, and according to the position of the center of mass of the hull section And the mathematical fitting model of the hull segment determines the point arrangement of each tire frame and the rising height of the screw. The specific process is as follows: figure 1 shown.

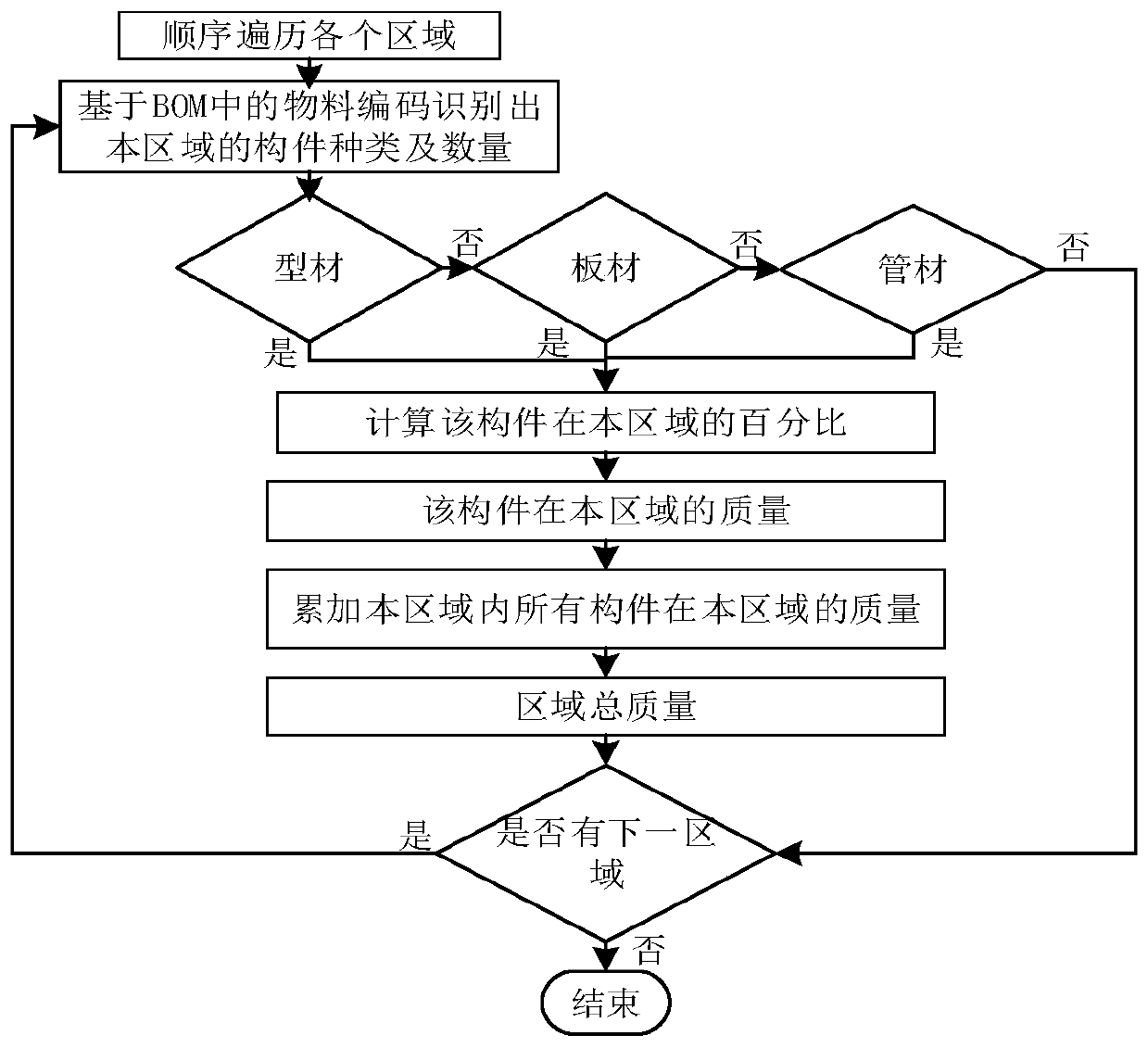

[0034] In the first step, each component is coded one by one according to the coding rules, and the component type f and the quantity k of various components on the hull surface segment are judged according to the material code in the BOM table.

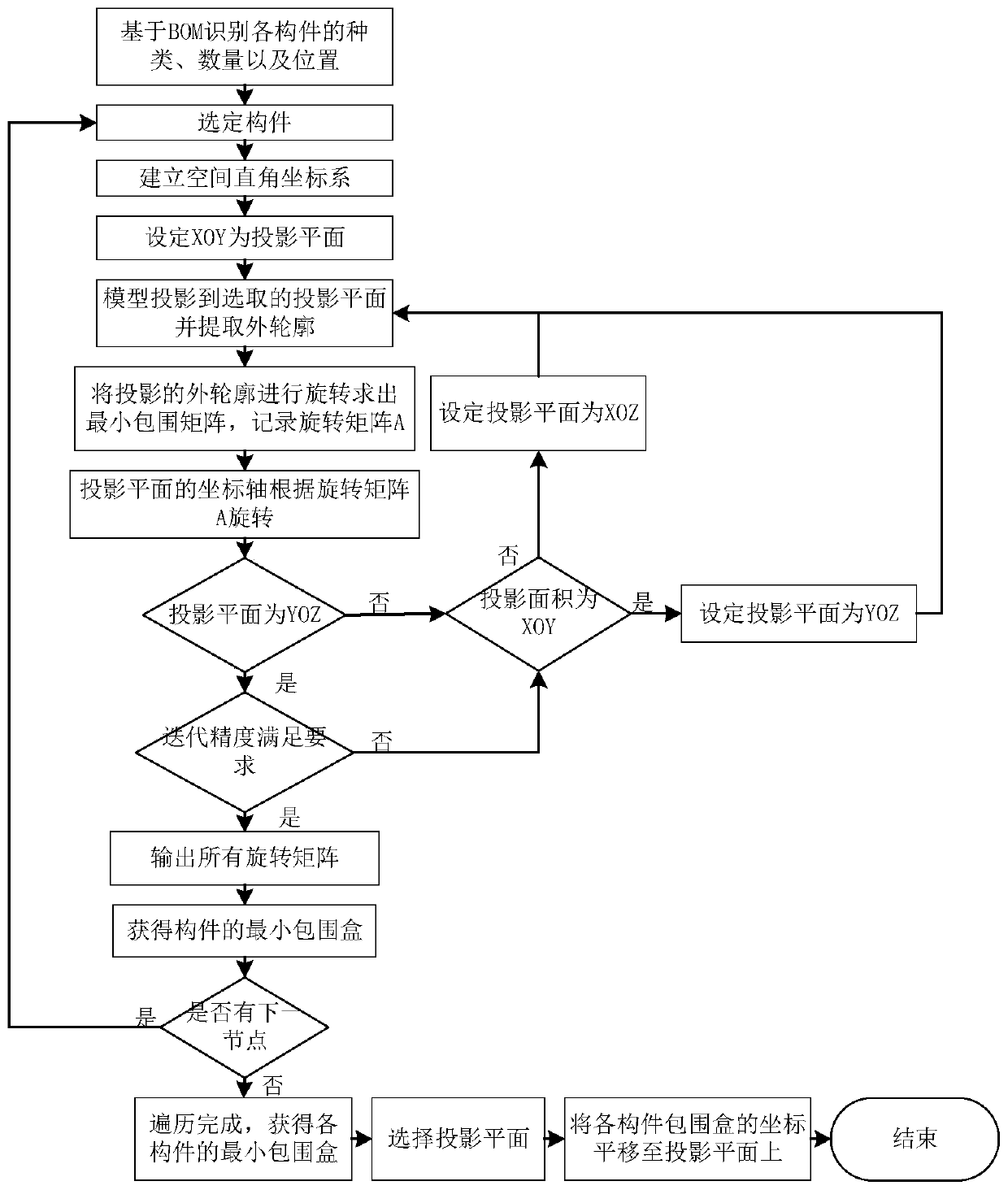

[0035] The second step is to use the bounding box algorithm to construct the minimum bounding box of each component. Its method is as figure 2 As shown, first determine the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com