An inclination measuring device and method for a cylinder head inclined hole

A technology of measuring device and cylinder head, applied in the direction of measuring device, using optical device, instrument, etc., can solve the problems to be improved, low efficiency, etc., and achieve the effect of high detection efficiency and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

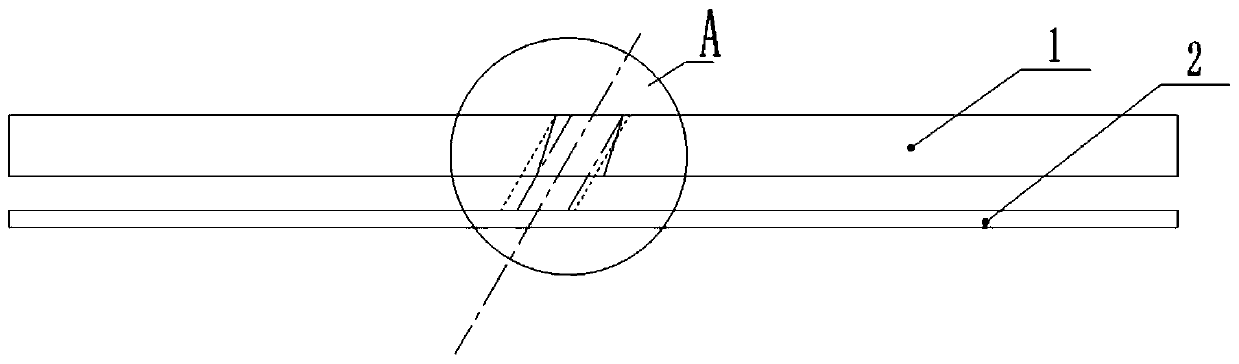

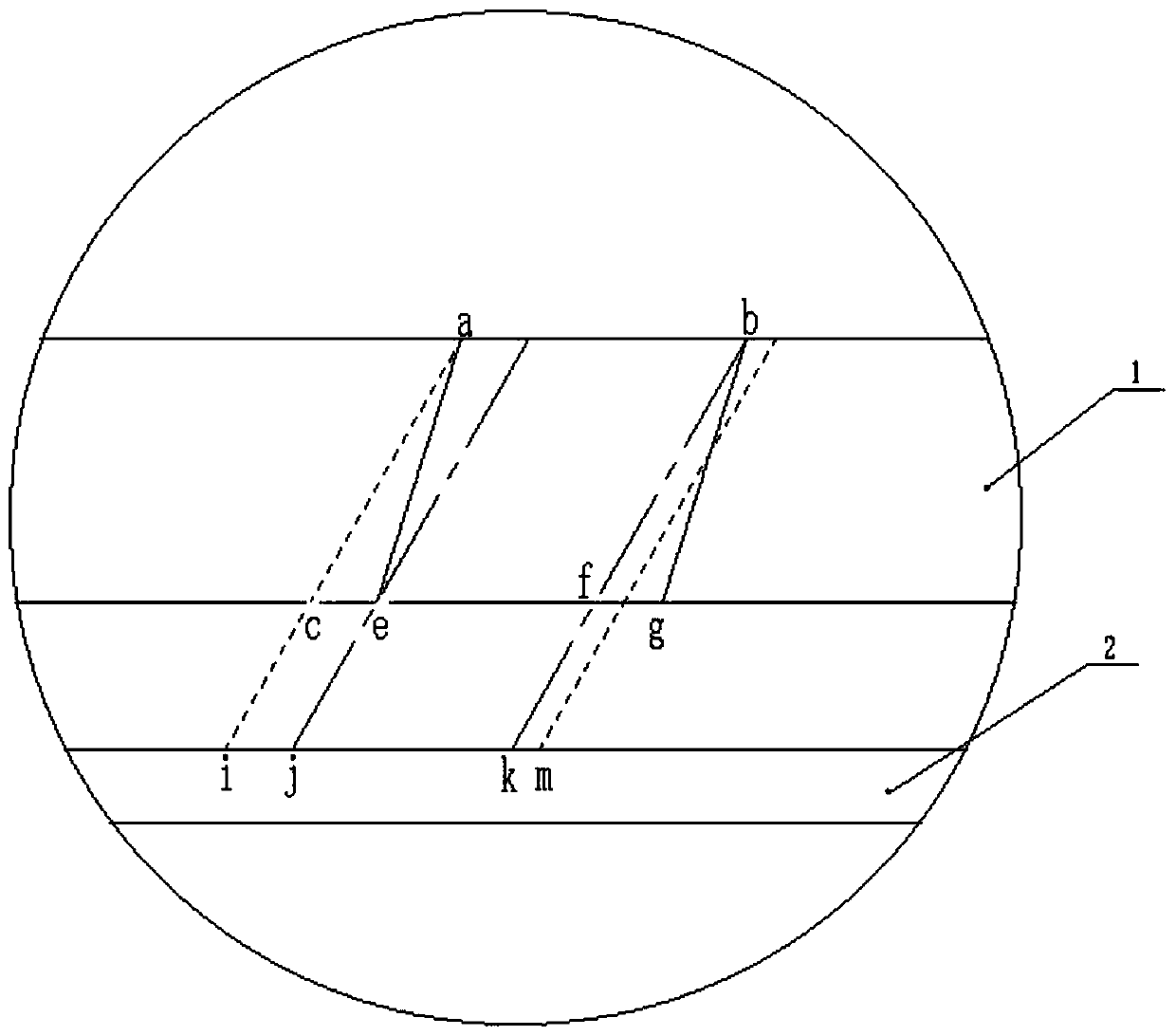

[0025] The embodiment of the invention provides a device and method for measuring the slope of a cylinder head slope hole.

[0026] The invention provides a device for measuring the inclination of a cylinder head inclined hole, which includes a photosensitive plate and a parallel light source. The position of the photosensitive plate is fixed along the horizontal direction, and the parallel light source is located above the photosensitive plate. Between the cylinder head and the parallel light source, the cylinder head is arranged at equal intervals on the cover transport mechanism. There are two sets of cover transport mechanisms, which are symmetrically distributed on both sides of the cylinder head. Each set of cover transport mechanism includes a conveyor belt and a driving wheel. On the side holding the cylinder head, the driving wheel drives the conveyor belt to move, and the driving wheel is connected with the intermittent movement mechanism, and the intermittent movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com