Method for detecting content of calcium in seamless calcium line

A technology of seamless calcium wire and detection method, which is applied in the field of chemical analysis, can solve the problem of inaccurate detection of calcium, and achieve the effects of reducing human and environmental hazards, easy operation, and less chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

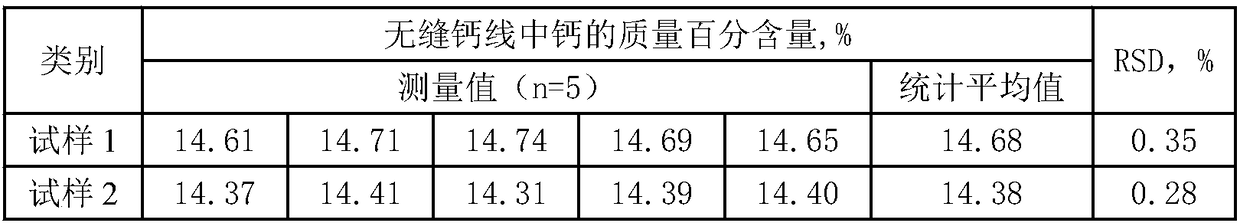

Examples

Embodiment Construction

[0015] The following specific examples are used to further illustrate the present invention. It should be understood that the following specific examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0016] A method for detecting calcium content in a seamless calcium wire, comprising the following steps:

[0017] 1) Prepare the sample. On the non-polluting and rust-free seamless calcium wire coil to be tested, cut 8 samples with a length of 10mm, discard 2 samples at the end, and seal the 6 samples in the middle After sealing, it is used for detection;

[0018] 2) Separate the calcium core in the sample and prepare the solution to be tested, weigh the quantitative sample and place it in a beaker, add 80 mL of distilled water at 70°C to the beaker to soak the sample for 25 minutes, and add the volume ratio It is a 1:1 hydrochloric acid solution, and the hydrochloric acid solution has a bulk density of 1.19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com