Method for rapid testing hydrogen sulfide content in drilling fluid

A detection method and technology of hydrogen sulfide, which are applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve the problems of cumbersome detection procedures and long detection time, and improve drilling efficiency. Efficiency, drilling cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] a, make detection test paper: the circular test paper that is 9mm in diameter is immersed in the lead acetate Pb (CH 3 COO) 2 solution, soak for 24 hours, take out and spread out to dry;

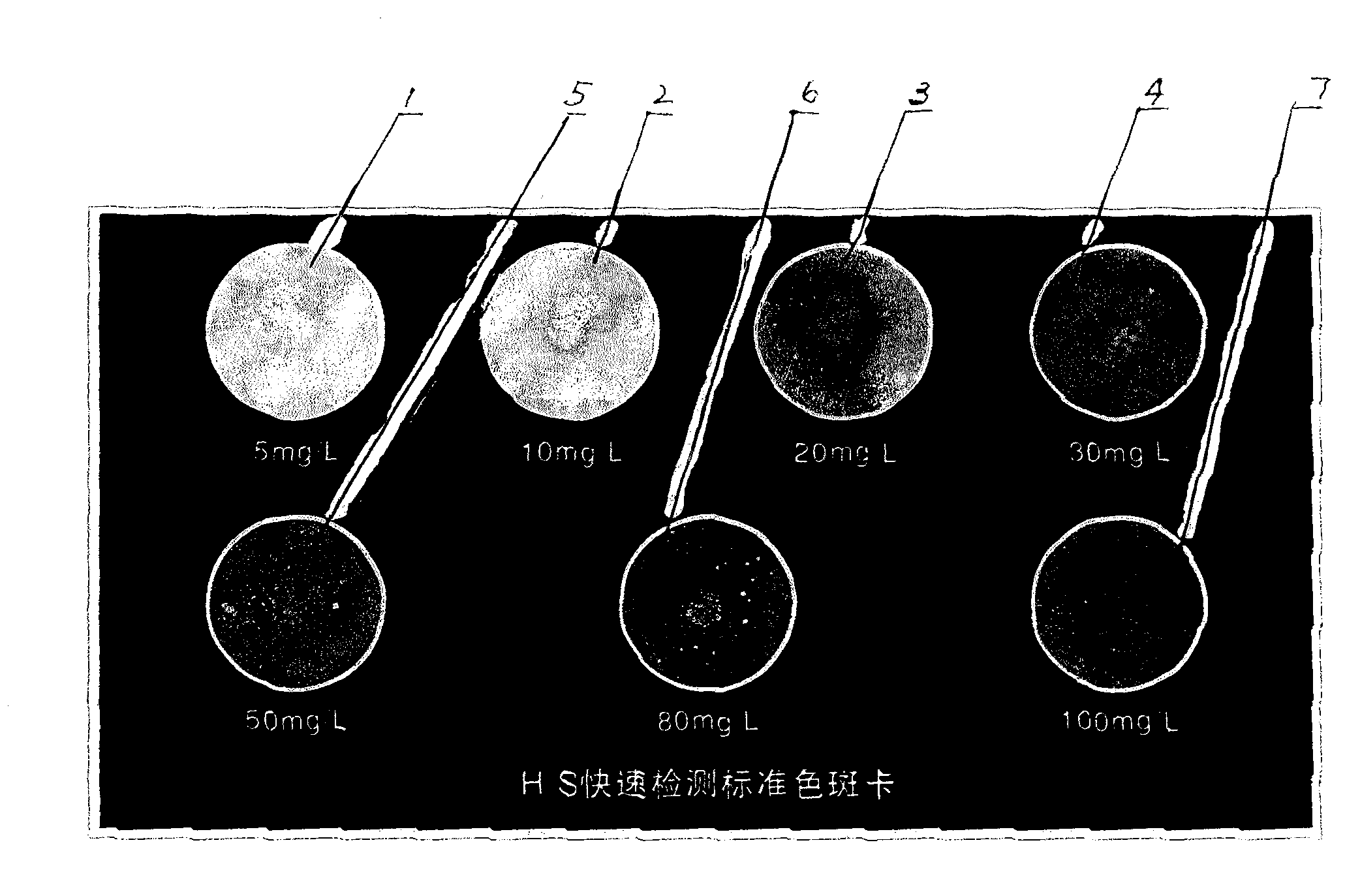

[0019] b. Preparation of sodium sulfide standard solution: dissolve 5mg, 10mg, 20mg, 30mg, 50mg, 80mg and 100mg of sodium sulfide into distilled water respectively, and prepare the contents of 5mg / L, 10mg / L, 20mg / L and 30mg respectively / L, 50mg / L, 80mg / L and 100mg / L sodium sulfide standard solution;

[0020] c. Make a standard color spot card

[0021] Take 2.5ml of sodium sulfide standard solution respectively in the reaction bottle, add 22.5ml of distilled water to make diluted sodium sulfide standard solution;

[0022] Put the detection test paper obtained in step a into the reaction bottle cap, put the diluted sodium sulfide standard solution in the reaction bottle respectively, add the composition containing NaHCO 3 , BaCl 2 and masking agent of polyvinylpyrrolidone 3g, 2-oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com