A kind of tea quality analysis method

A quality analysis and quality technology, applied in the analysis of materials, thermal stimulation analysis, material stimulation analysis, etc., can solve the problems of no complete consensus and no systematic and comprehensive tea quality control technical plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

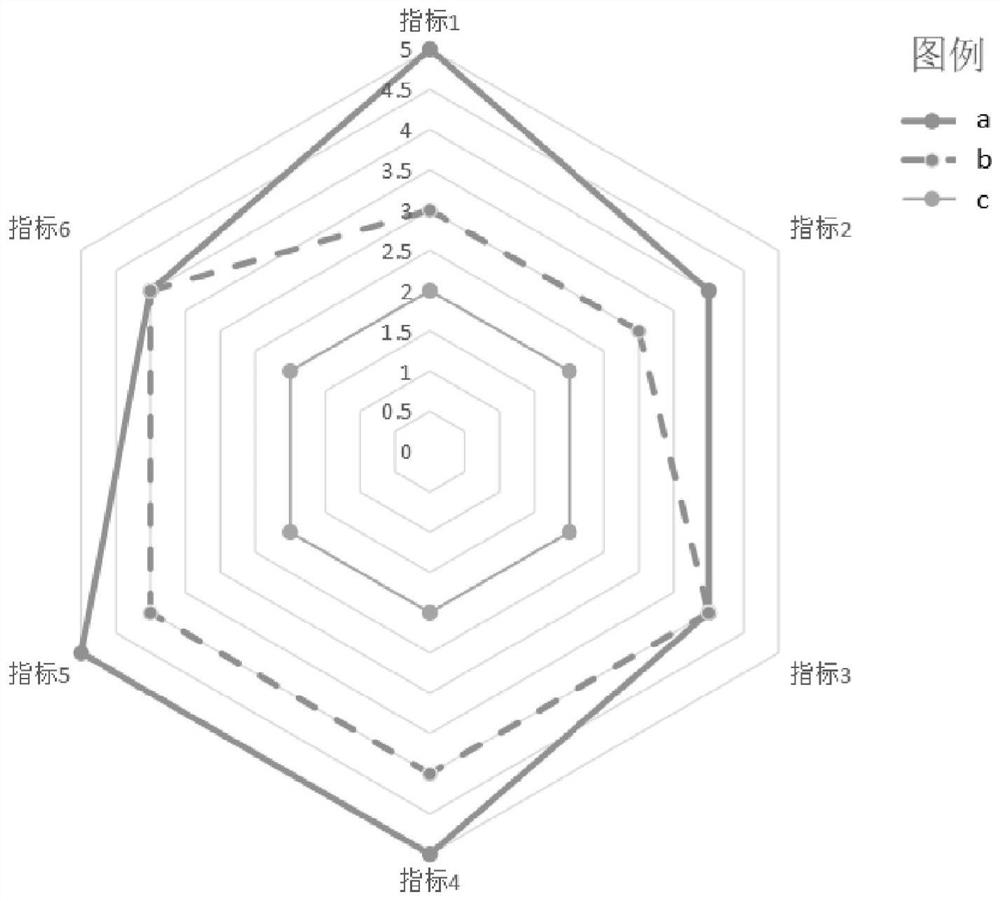

[0079] According to the technical scheme of the present invention, a certain green tea variety a is made after picking, airing, and finishing, and is preserved under different conditions, including: ordinary aluminum-plastic composite bag sealing (vacuum or nitrogen filling) packaging, aluminum can sealing (air or nitrogen filling) ) packaging, ordinary metal box (unsealed) packaging, and porcelain jar packaging, respectively stored at room temperature and refrigerated conditions for 2 years, during which they were taken out every 3-6 months for quality evaluation.

[0080] test table

[0081] Packaging form \ storage conditions Normal temperature (25±5℃) Refrigerated (0-5°C)

[0082] a Ordinary aluminum-plastic composite bag sealed (vacuum) (regular quality evaluation) (regular quality evaluation) b Ordinary aluminum-plastic composite bag sealed (filled with nitrogen) (regular quality evaluation) (regular quality evaluation) c alu...

Embodiment 2

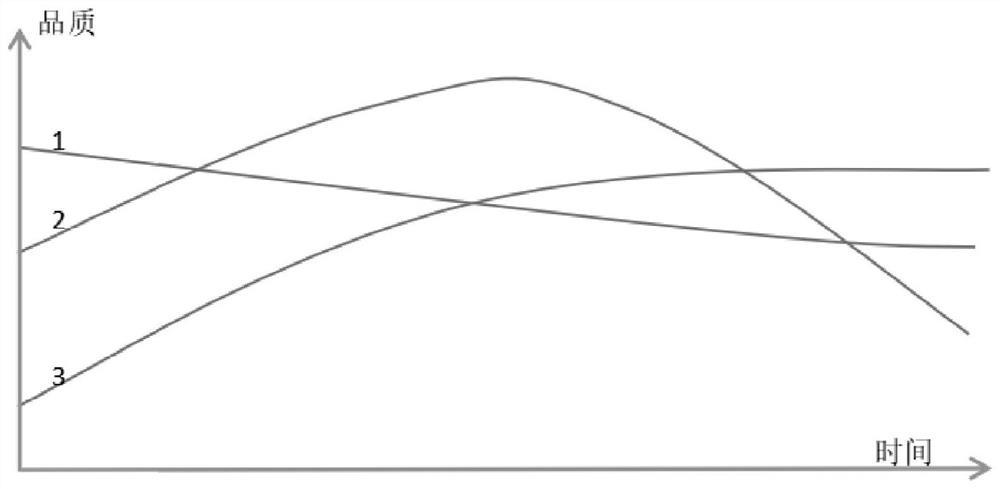

[0116] A certain green tea S was subjected to quality analysis as in Example 1, and it was found that its main quality-influencing indicators were moisture and volatile alkanes. Moisture is a category B indicator (negatively correlated with tea quality), the lower the value, the better the quality. The higher the volatile alkanes, the better the quality. Combined with the sensory evaluation, the water content of the excellent grade should be less than 6%, the proportion of volatile components should be more than 15%, and the corresponding quality grade is 0-22. Using aluminum-plastic composite packaging, the moisture content of the green tea S will increase from 5.0% to 7.0% during the 2-year shelf life under standard conditions (25°C / RH65%), and the volatile alkanes will decrease from 20% to 8% of the total volatile components. That is, the green tea quality grade index changes from 0 grade to [(7-5) / 5+(20-8) / 20] / 2=50%=50 grade within the shelf life under the predetermined p...

Embodiment 3

[0118] The quality analysis of a flower-flavored tea was carried out in the same manner as in Example 1, and it was found that the main quality-influencing indicators were moisture and floral fragrance scores. Moisture is a category B indicator (negatively correlated with tea quality), the lower the value, the better the quality. The higher the floral fragrance, the better the quality. Combined with the sensory evaluation, the water content of the superior grade should be less than 6%, and the floral fragrance score should be above 4, corresponding to a quality grade of 0-20. Using aluminum-plastic composite packaging, the moisture content of the tea will increase from 5.0% to 7.0% during the 2-year shelf life under standard conditions (25°C / RH65%), and the flower fragrance score will decrease from 5 to 1. That is, the green tea quality grade index changes from grade 0 to grade [(7-5) / 5+(5-1) / 5] / 2=60%=grade 60 within the shelf life under predetermined packaging conditions. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com