Anti-thrust mushroom-shaped member and motor having same

A technology of mushroom-shaped components, applied in the direction of static components of magnetic circuits, rotating components against centrifugal force, electromechanical devices, etc., can solve problems such as disturbing vibration and noise, and poor self-locking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

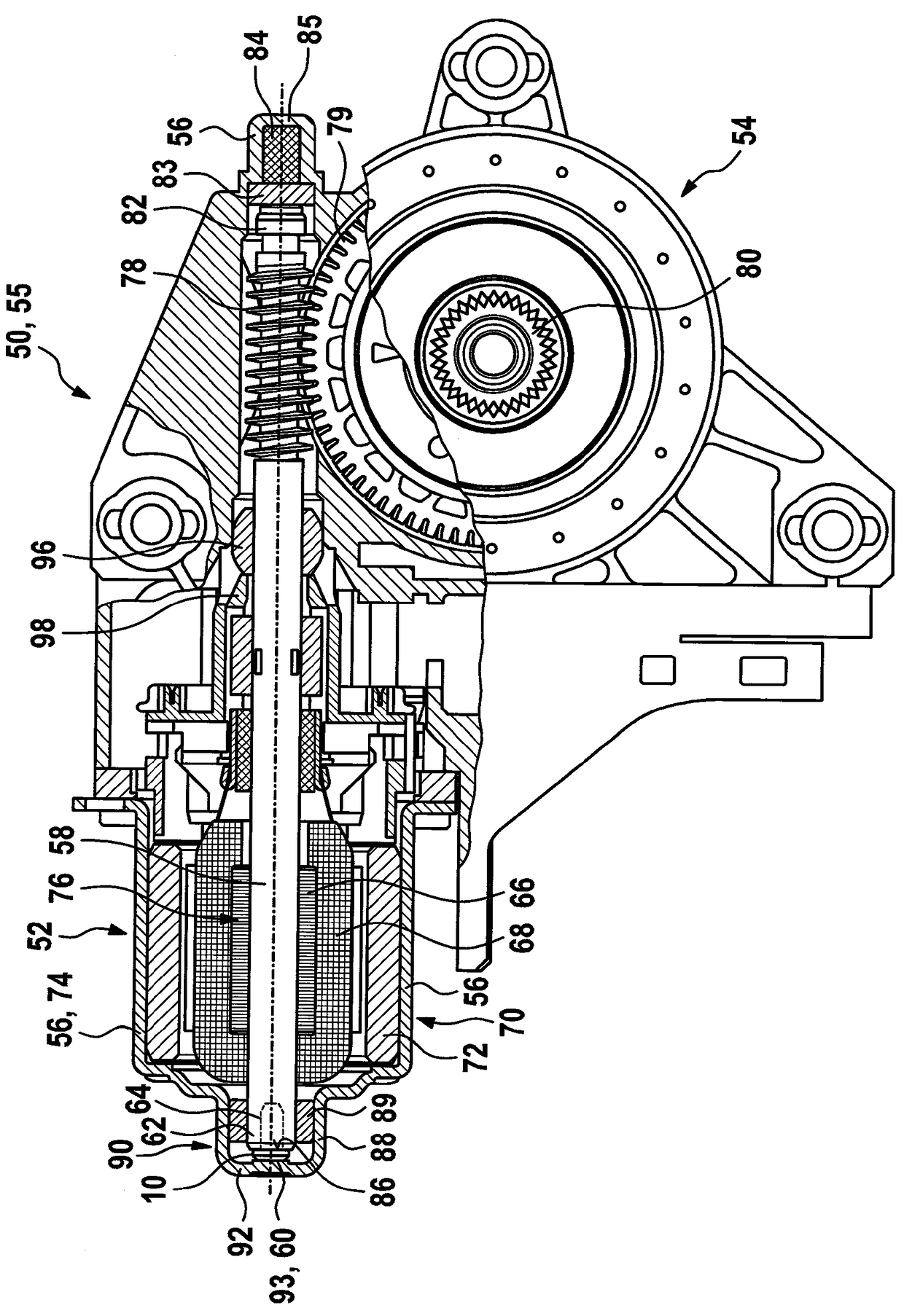

[0019] exist figure 1 shows an electric motor 50, wherein an electric motor 52 and a transmission 54—in particular a worm gear—form a transmission drive unit 55, such as the transmission drive unit for adjusting sliding roofs, window panes in motor vehicles Or seat parts like that. The electric motor 52 has a stator 70 , wherein permanent magnets 72 are arranged in a pole housing 74 . A rotor 76 is arranged in the stator 70 , wherein an armature assembly 66 with coils 68 is fastened on the rotor shaft 58 . For torque transmission from the electric motor 52 , a worm 78 is arranged on the rotor shaft 58 , which engages in a worm wheel 79 of the transmission 54 . The worm gear 79 is connected to an output pinion 80 , on which an output torque for adjusting a movable part, for example a window pane, is provided. On the axial end 82 of the rotor shaft 58 , an elastic damping element 84 , for example damping rubber, is arranged between the rotor shaft and the wall 85 of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com