Crop fertilizing device

A fertilization device and crop technology, applied in fertilization devices, agriculture, planting methods, etc., can solve the problems of waste, burned roots, low fertilizer utilization rate, etc., and achieve the effect of improving absorption rate and avoiding lumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

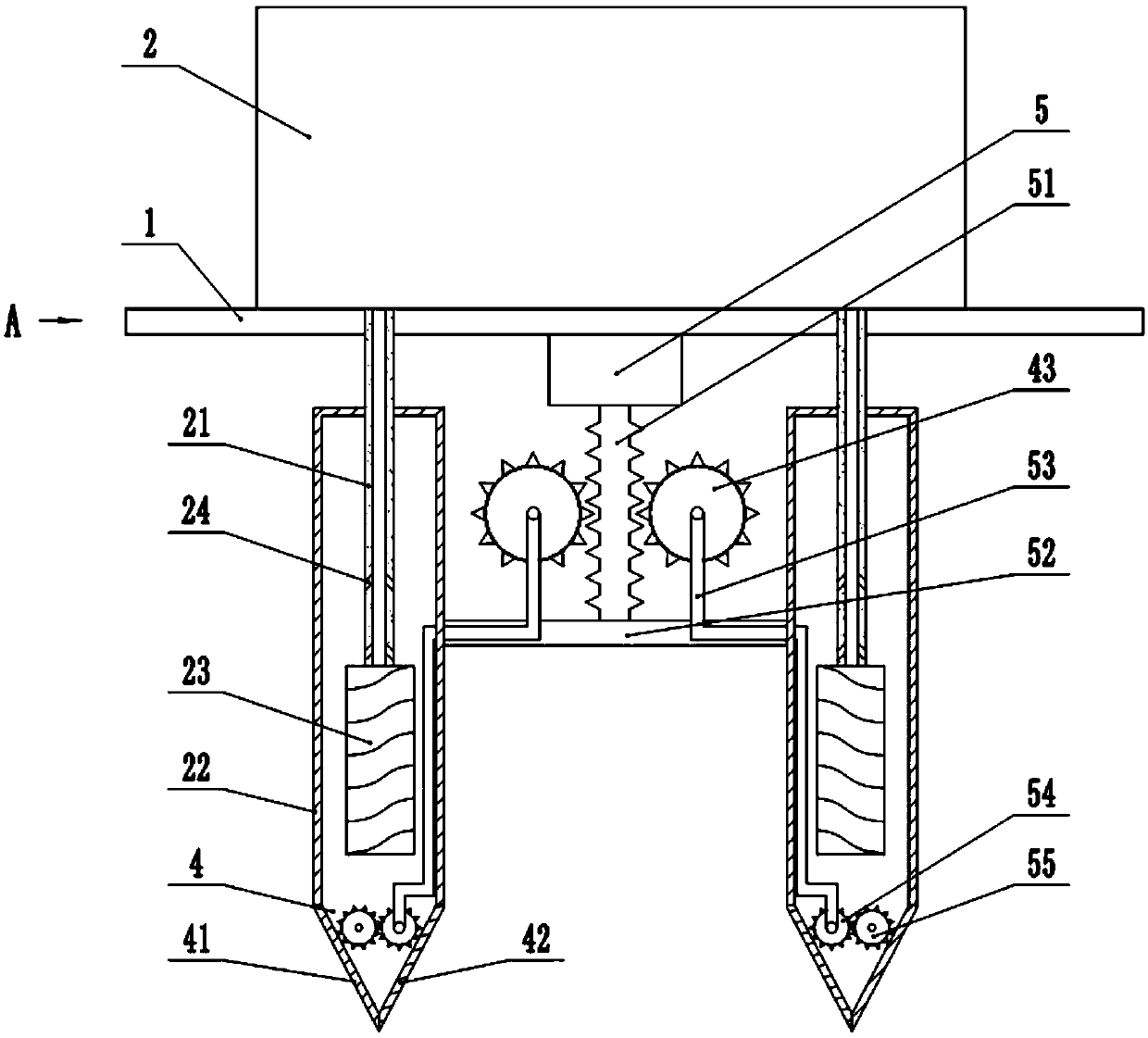

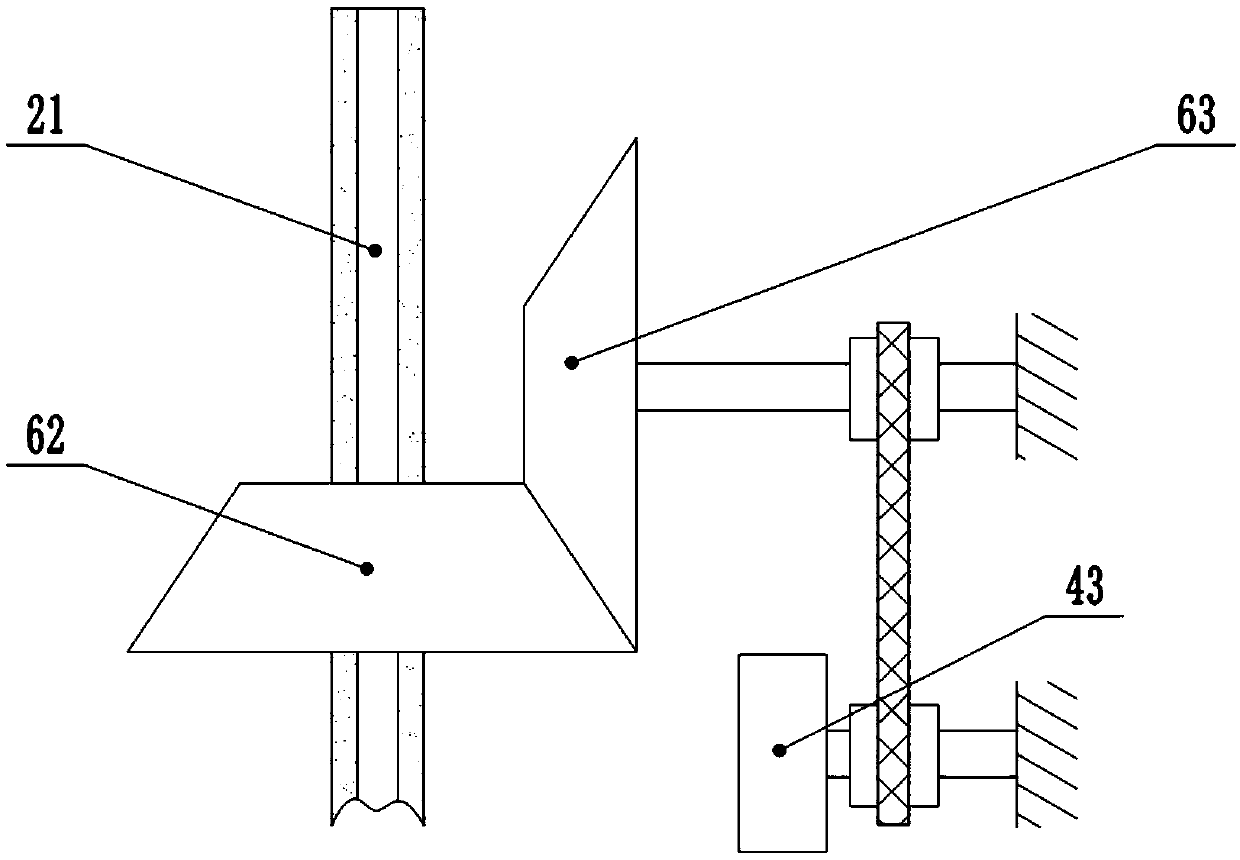

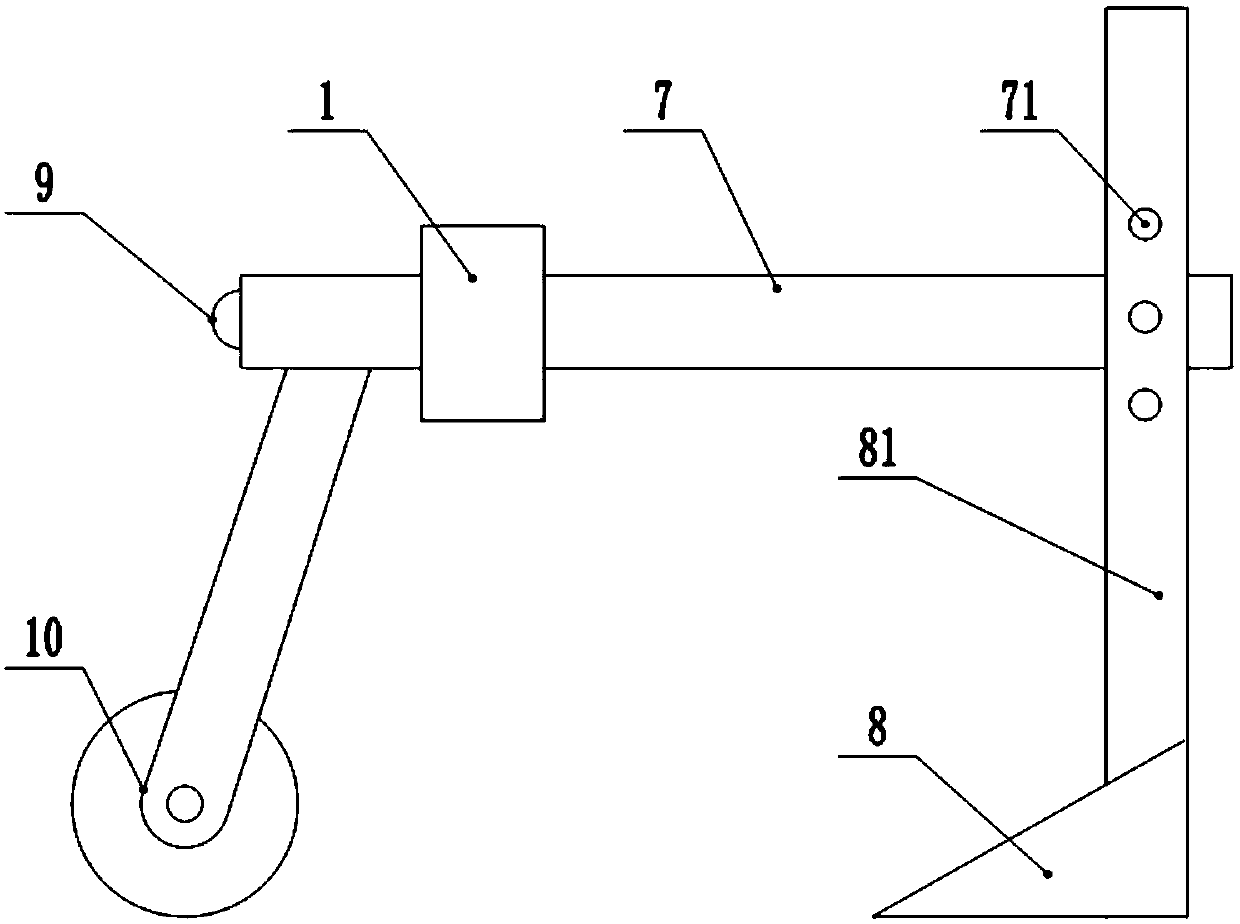

[0024] The reference numerals in the drawings of the description include: baffle plate 1, fertilizer box 2, fertilization pipe 21, stirring box 22, stirring rod 23, discharge hole 24, hole opener 4, first hole opening plate 41, second opening hole Hole plate 42, first gear 43, cylinder 5, rack 51, linkage plate 52, flexible shaft 53, third gear 54, fourth gear 55, first bevel gear 62, second bevel gear 63, beam 7, adjustment Hole 71, plow share 8, support arm 81, draw ring 9, support wheel 10.

[0025] The embodiment is basically as attached figure 1 Shown:

[0026] A crop fertilization device, including a frame, a baffle 1, a fertilizer box 2 and a fertilization mechanism, the fertilizer box 2 is located above the baffle 1, the fertilization mechanism is located below the baffle 1, a cylinder 5 is arranged at the bottom of the baffle 1, and the bottom of the cylinder 5 is A rack 51 is fixed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com