Wringing mop bucket for flat mop

A flat mop and mop bucket technology, applied in the field of mop buckets, can solve the problems of inability to squeeze dry, affect the effect of squeezing water, and fluctuation of the wiper strip, and achieve the ability to strengthen the squeezing effect, improve the squeezing effect, and reduce fluctuations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

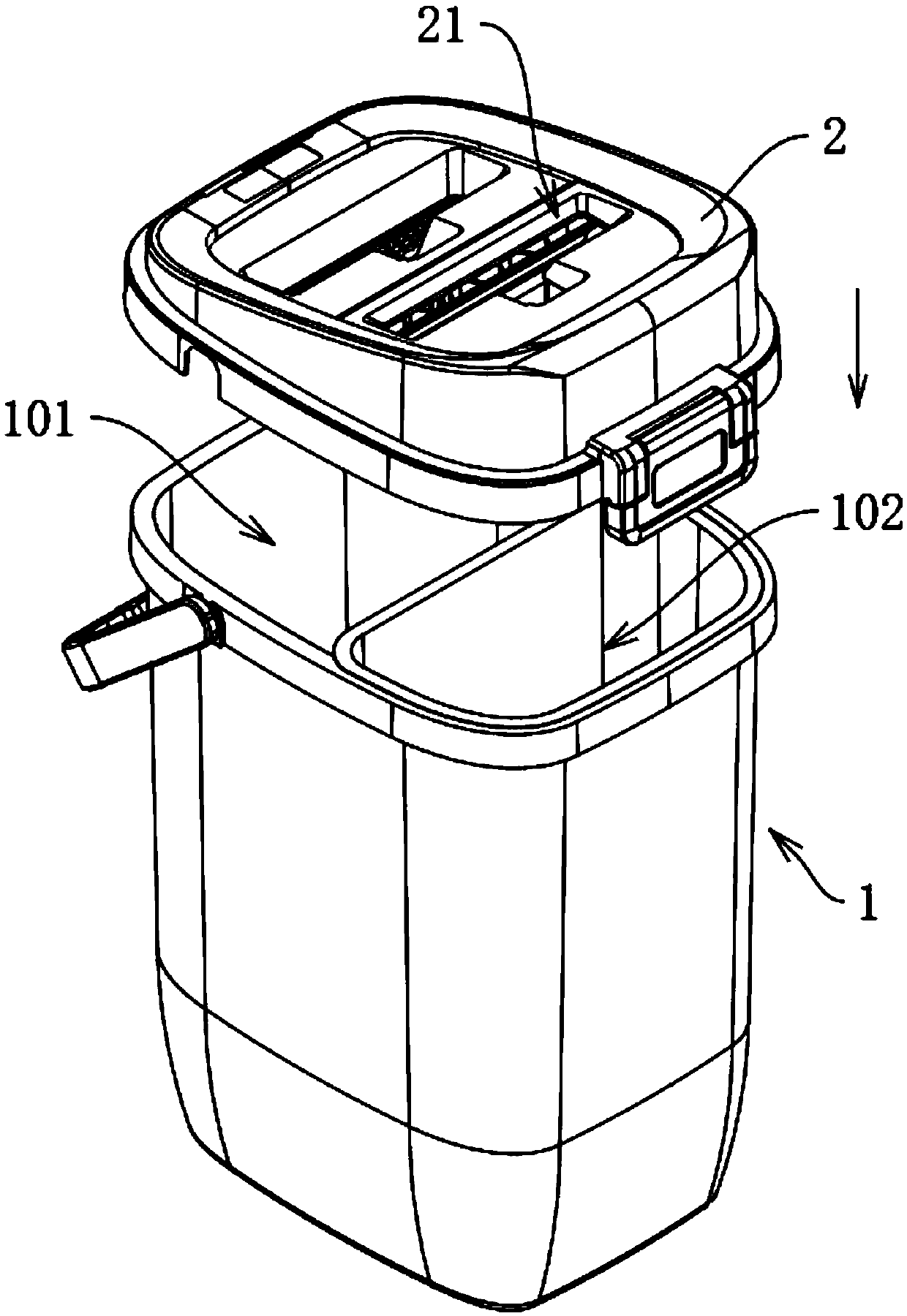

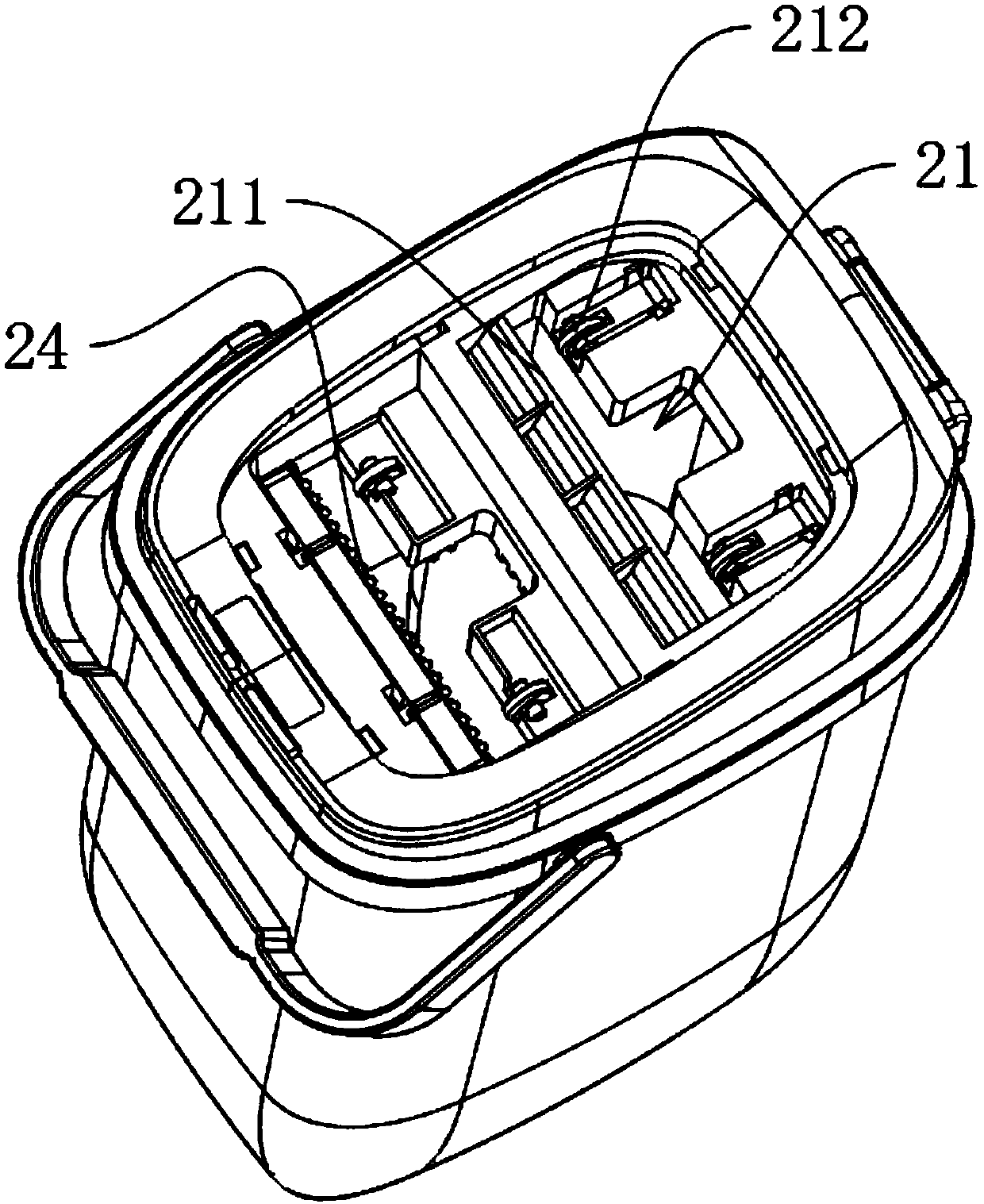

[0039] Embodiment: a kind of flat mop is squeezed water mop bucket, as figure 1 and figure 2 As shown: includes a bucket body 1, the bucket body has a cleaning area 101 and a wiper area 102, the cleaning area and the wiper area are not connected to each other, the wiper area is provided with a water retaining cover 2, the water retaining The cover has a wiper port 21 for the flat mop to pass through, and the wiper port is provided with a wiper strip 211 for squeezing the wiper of the flat mop and a propping member 212 opposite to the wiper strip;

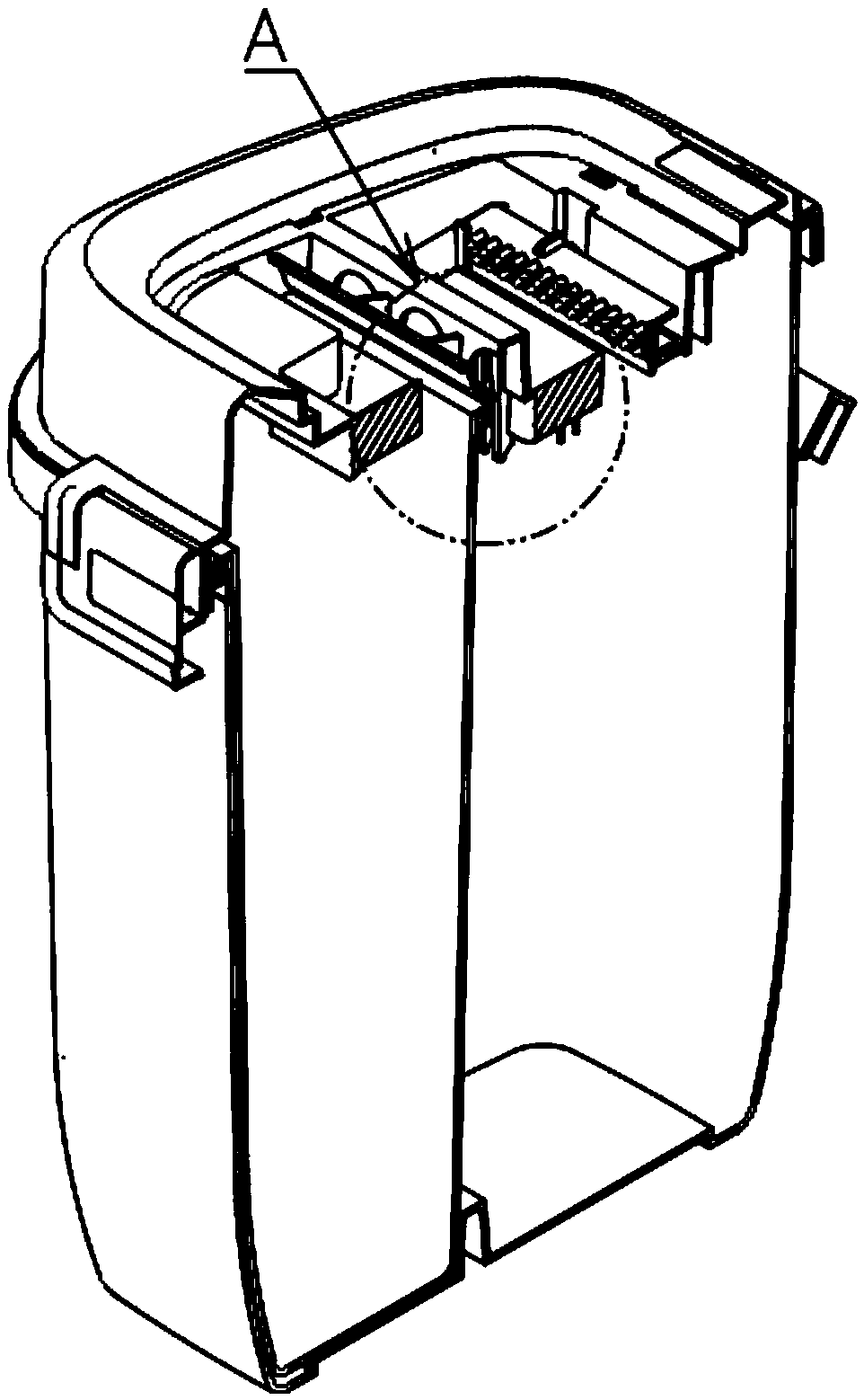

[0040] Such as image 3 and Figure 4 As shown: the wiper strip 211 is fixed, the side of the wiper strip in contact with the wiper of the flat mop is the wiper side, and the side opposite to the wiper side is the drain side, the The wiper side of the wiper strip is higher than its drain side, and the upper surface of the wiper strip forms an inclined water guide slope 2111, and the bottom end of the water guide slope is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com