Automobile radiator shock pad

An automobile radiator and shock-absorbing pad technology, which is applied to the arrangement of vehicle components and power unit cooling combination, power unit and other directions, can solve the problem that the radiator mounting pin is difficult to insert into the shock-absorbing pad, the practical load-bearing capacity is insufficient, and the structure is not reasonable enough. and other problems, to achieve the effect of improving shipping efficiency and installation efficiency, large bearing capacity, and preventing falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and specific embodiments, so that those skilled in the art can understand.

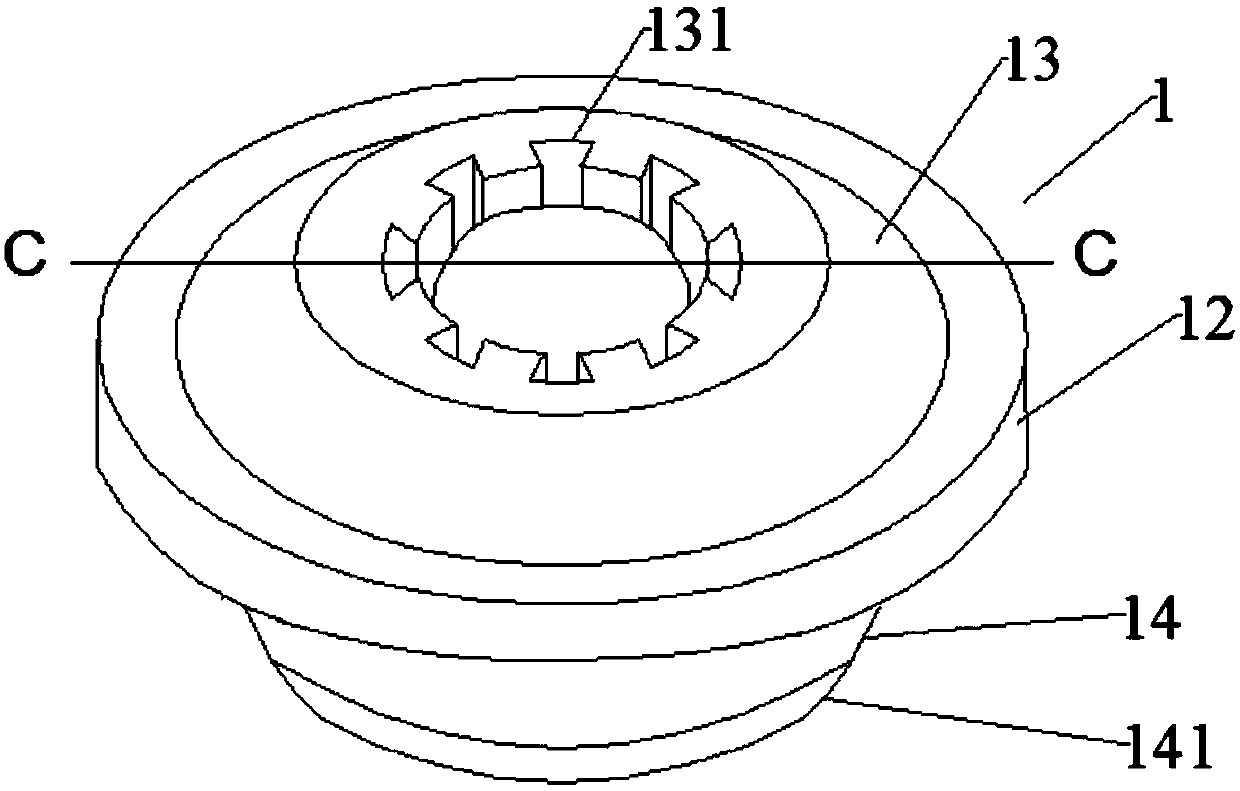

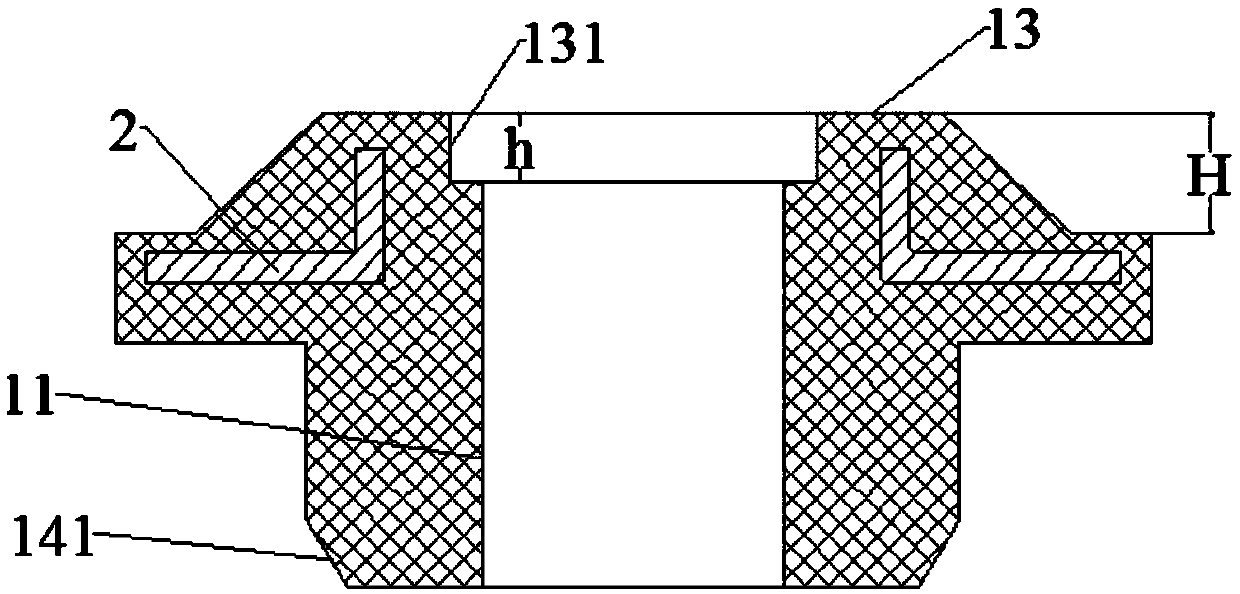

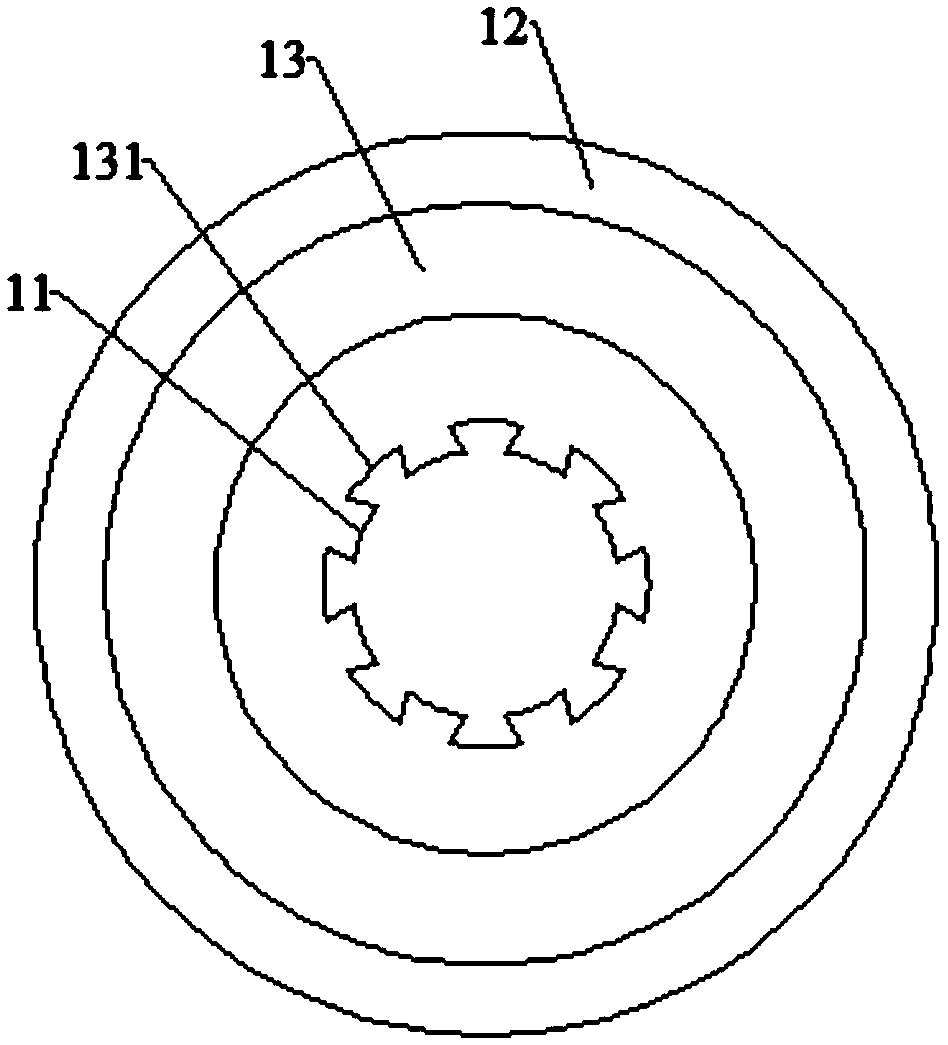

[0023] Figure 1-3 Shown is the automobile radiator shock absorber of the present invention, comprising an integrally formed shock absorber body 1 with an axial through hole 11 in the center, the shock absorber body 1 includes a disc body 12, and a disc body 12 The upper mounting round platform 13 connected with the upper end surface and the lower mounting cylinder 14 connected with the lower end surface of the disc body 12, the axis line of the disc body 12, the upper mounting round platform 13 and the lower mounting cylinder 14 is in line with the axial through hole 11 have the same center line, and the upper end surface of the upper mounting round platform 13 is provided with a plurality of tooth grooves 131 communicating with the axial through hole 11 and uniformly distributed radially outward alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com