A high-temperature melting device for non-woven fabric production

A high-temperature melting, non-woven technology, used in textiles and papermaking, melting of filament raw materials, fiber processing, etc., can solve the problems of the melting furnace not being shockproof, the material cannot be fully melted, and the energy saving and environmental protection cannot be achieved. achieve the effect of avoiding heat overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

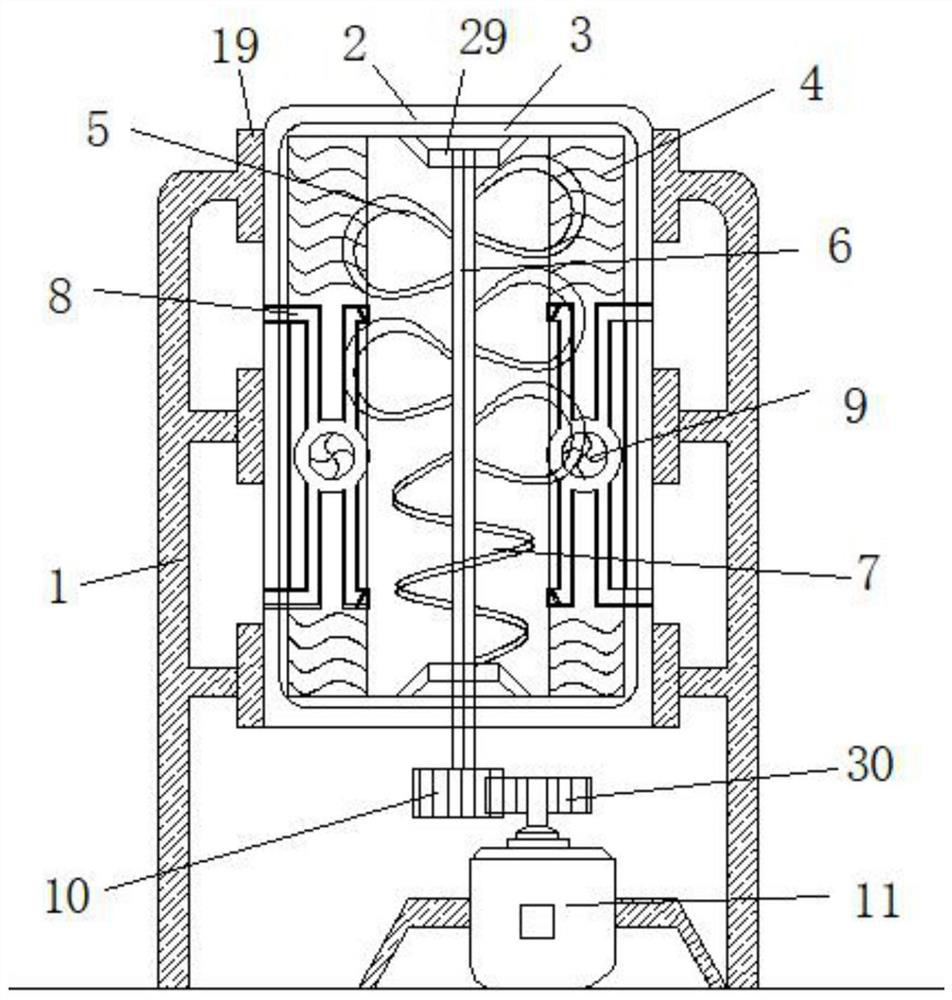

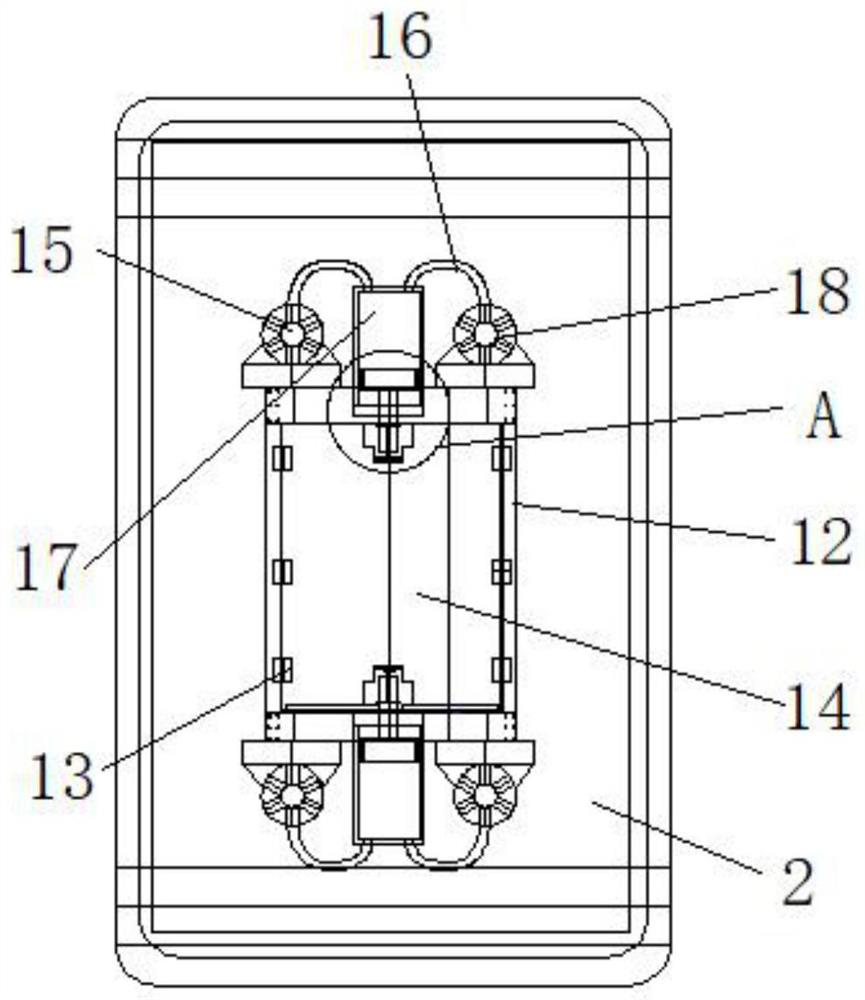

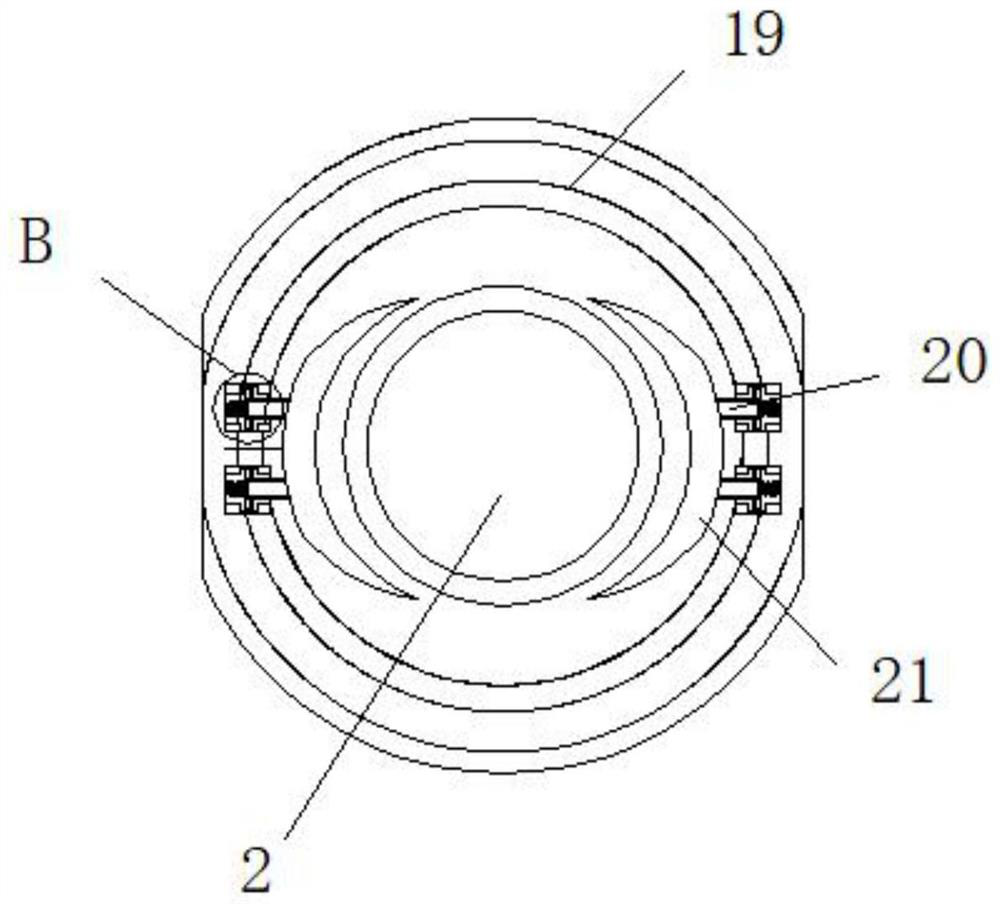

[0027] See Figure 1-5A method of manufacturing a nonwoven fabric with a high temperature melting apparatus includes a support frame 1, a melting furnace 2, insulating layer 3, 4 wire melting, stirring fan 5, the rotary shaft 6, a spiral sheet 7, the channel 8, turbofan 9, The first gear 10, a motor 11, a lintel 12, the hinge 13, the door panel 14, suction pump 15, line 16, cylinders 17, blow air pump 18, the retainer ring 19, connecting rod 20, clamp block 21, a piston 22, lever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com