Elastic strip fastener structure for small-radius track steel rail

A small-radius, steel-rail technology, used in rails, fixed rails, roads, etc., can solve problems such as difficulty in maintaining stable track geometry, increase line maintenance costs, and severe wear and tear of track components, to avoid falling off or theft and loss, The effect of improving safety and reliability and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

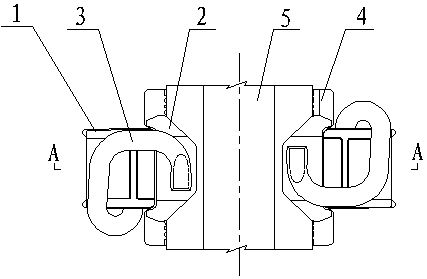

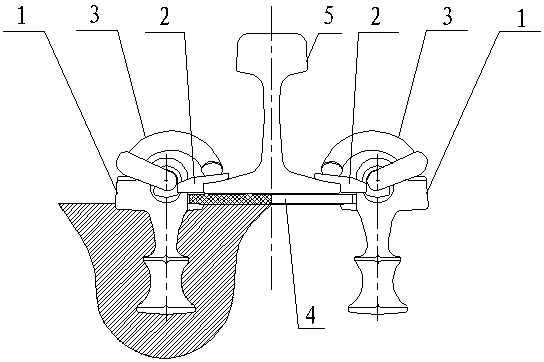

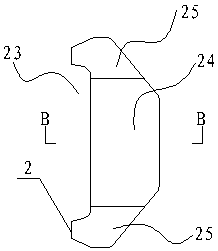

[0036] Such as Figure 1 to Figure 13 As shown, a spring-bar fastener structure for small-radius rails of the present invention includes rails 5 installed on the rails of sleepers in the front-to-back direction. The rails of the sleepers are located on the left and right sides of the rails 5. There are embedded fixed seat 1. The pre-embedded fixing seat 1 and the corresponding side surface of the steel rail 5 are fitted with a gauge stopper 2 to provide insulation and fixation. The inner side of the gauge stop 2 is provided with a protrusion 21 extending inward and laying on the upper side of the rail bottom. The protrusion 21 is provided with a downwardly protruding jaw 22 and cooperates with the protrusion 21 to form a card slot , The rail bottom of the steel rail 5 is clamped in the slot; the outer side of the gauge block 2 is set as a bayonet 23 that matches the corresponding embedded fixing seat, and the gauge block 2 passes through the bayonet 23 and the corresponding pre...

Embodiment 2

[0048] Such as Figure 14 to Figure 15 As shown, the difference between this embodiment and the first embodiment is that: an anti-theft structure is provided between the support portion of the e-shaped elastic bar 3 and the embedded fixing seat 1, and the anti-theft structure includes the lower side of the supporting portion of the e-shaped elastic bar 3 The anti-returning protrusion 6 and the positioning recess 7 provided on the upper side of the embedded fixing seat, the anti-returning protrusion 6 is engaged with the positioning recess 7; and along the length direction of the support portion of the e-shaped elastic strip 3, The anti-return protrusion 6 is divided into the installation forward side and the disassembly backward side. The installation forward side 61 of the anti-return protrusion 6 and the e-shaped elastic bar are smoothly transitioned, and the disassembly rear side 62 of the anti-return protrusion 6 and the e-shaped elastic bar form a stop Retreat the facade. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com