Simple bracket structure of back wall and construction method based on simple bracket structure of back wall

A technology of support structure and construction method, which can be used in infrastructure engineering, underwater structures, artificial islands, etc., and can solve problems such as reducing construction efficiency and conflicting platform cover beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

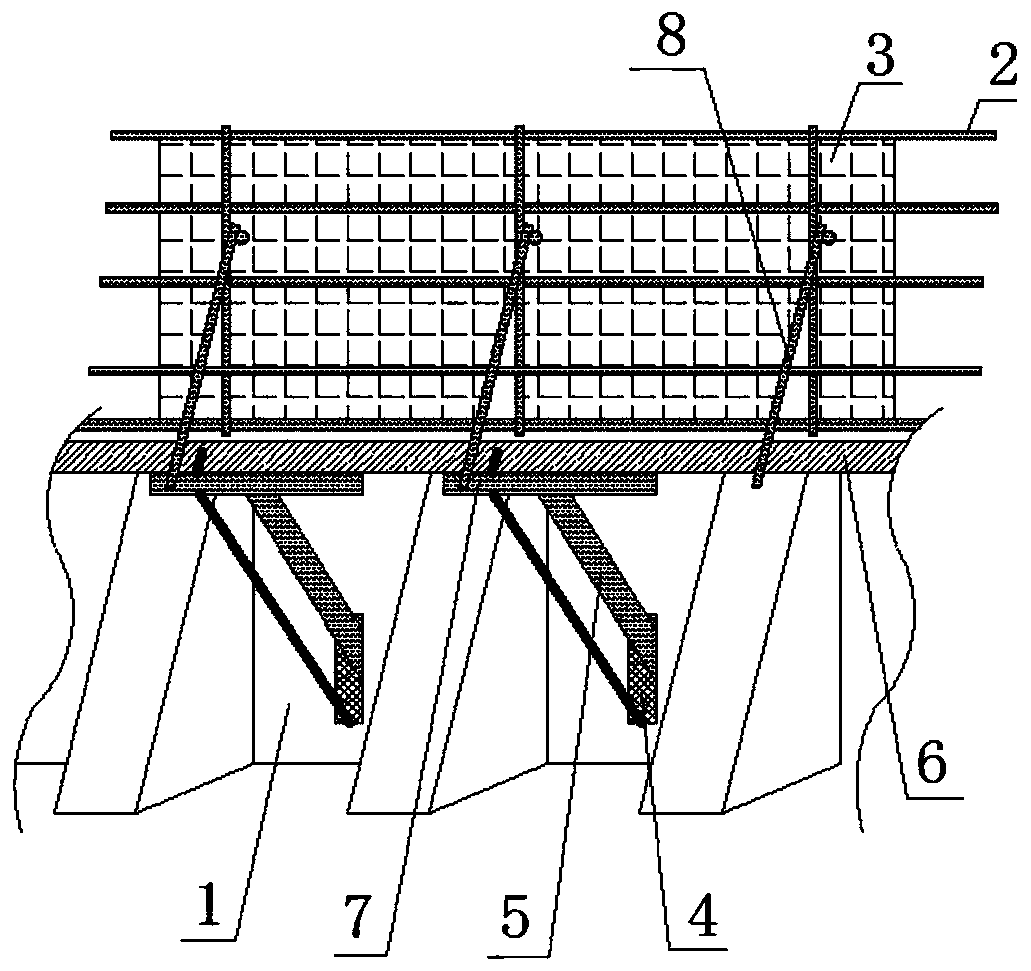

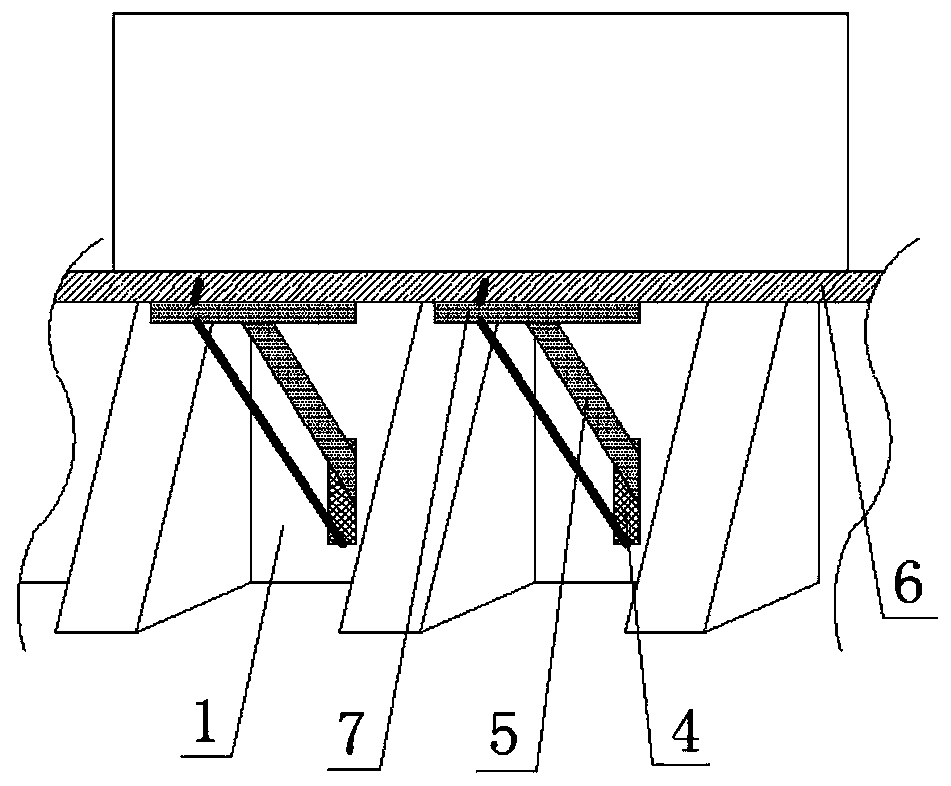

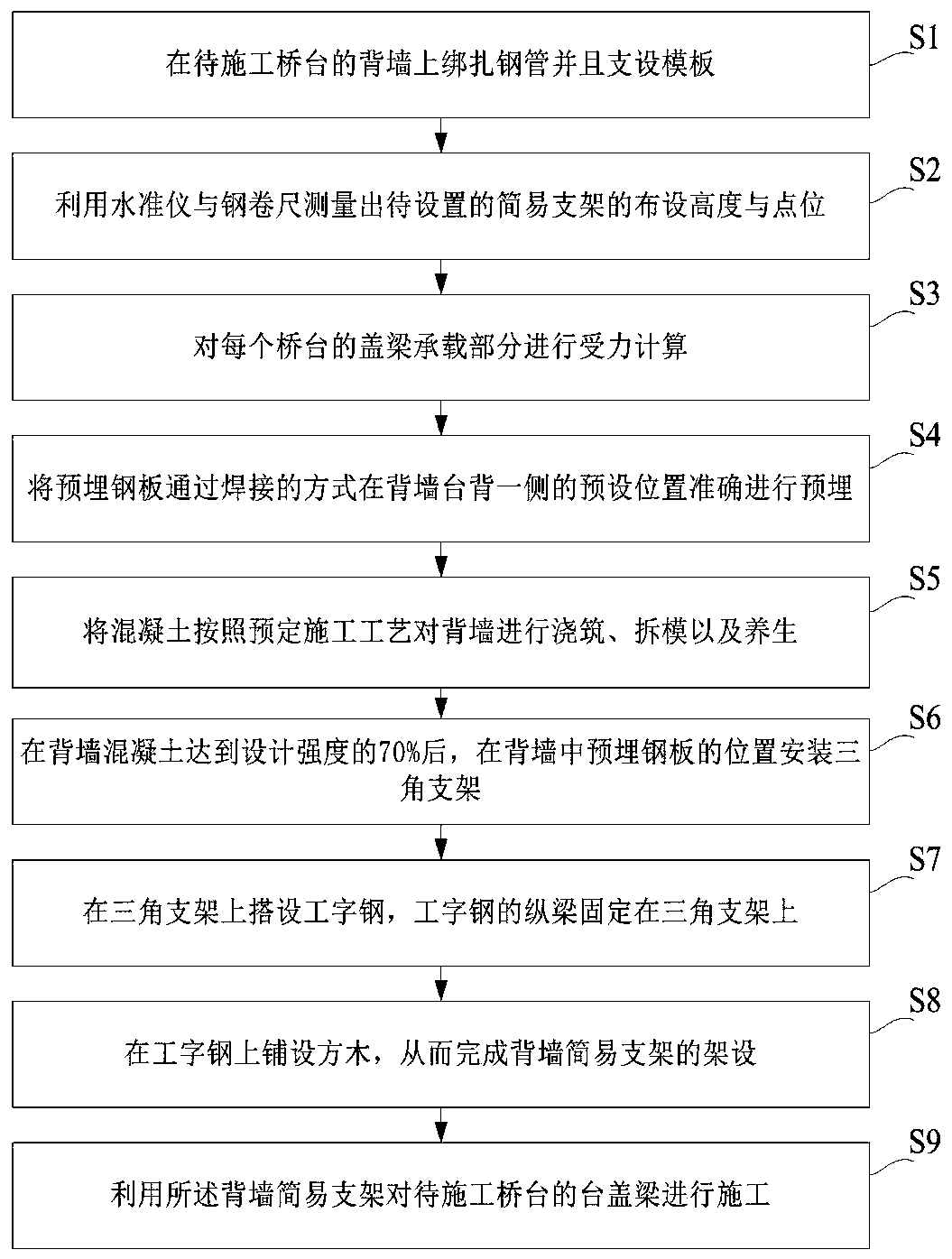

[0030] see Figure 1 to Figure 2 , the embodiment of the present application first provides a simple support structure for the back wall, including: abutment back wall 1, steel pipe 2, formwork 3, embedded steel plate 4, triangular support 5, square wood 6, I-beam 7 and formwork braces Item 8.

[0031] Wherein, there are multiple steel pipes 2, the template 3 is erected on the abutment back wall 1 through the steel pipes 2, and one end of the I-beam 7 is vertically fixed to the abutment back wall 1 Above, the embedded steel plate 4 is arranged on the abutment back wall 1 and located below the I-beam 7; one end of the triangular bracket 5 is fixed on the embedded steel plate 4, and the triangular bracket The other end of 5 is fixed on the bottom of the I-beam 7, and the square wood 6 is arranged on the I-beam 7. The bottom of the template brace 8 is fixed to the I-beam 7 , and the top of the template brace 8 supports the template 3 . The formwork braces 8 can specifically ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com