Efficient culvert construction mobile truss system and construction technology

A truss system and mobile technology, which is applied in the field of efficient culvert construction mobile truss system and construction technology, can solve the problems of trolley moving time and labor investment, the inability to realize secondary continuous utilization, and long occupation time of internal formwork, etc. , to achieve the effect of reducing the effective use time and investment, improving the utilization rate of the formwork, and improving the binding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

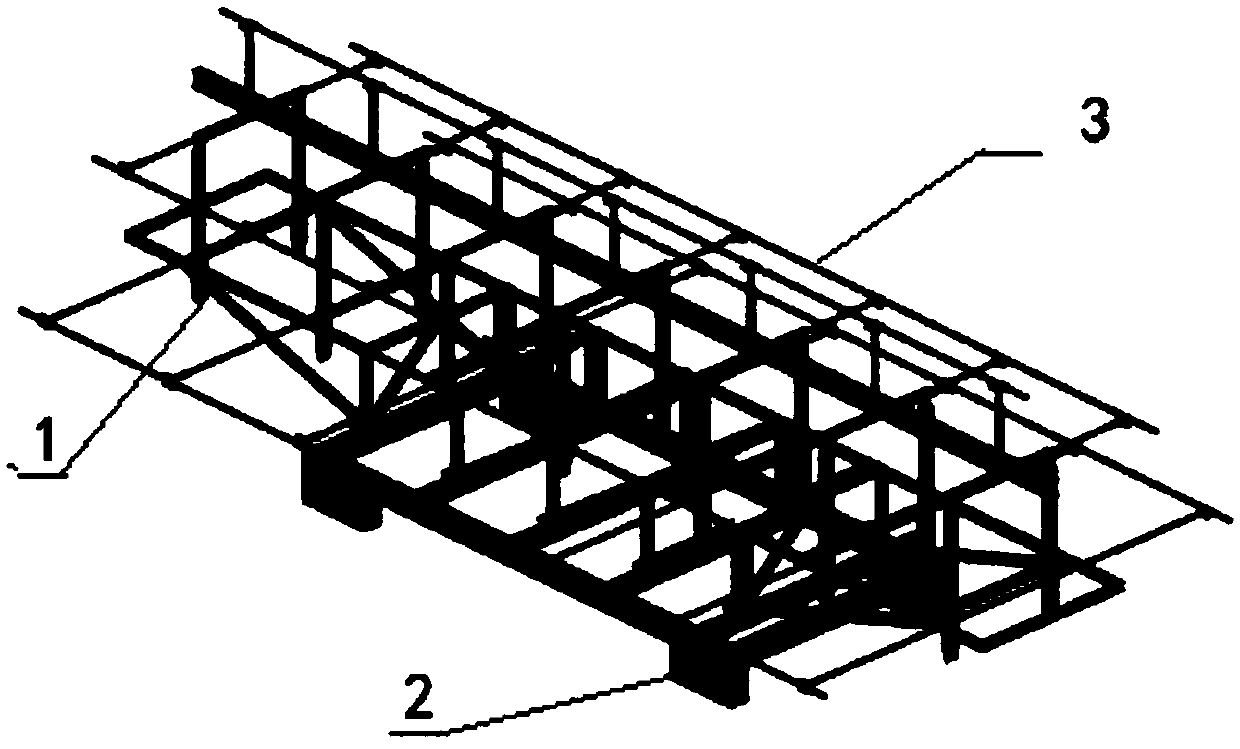

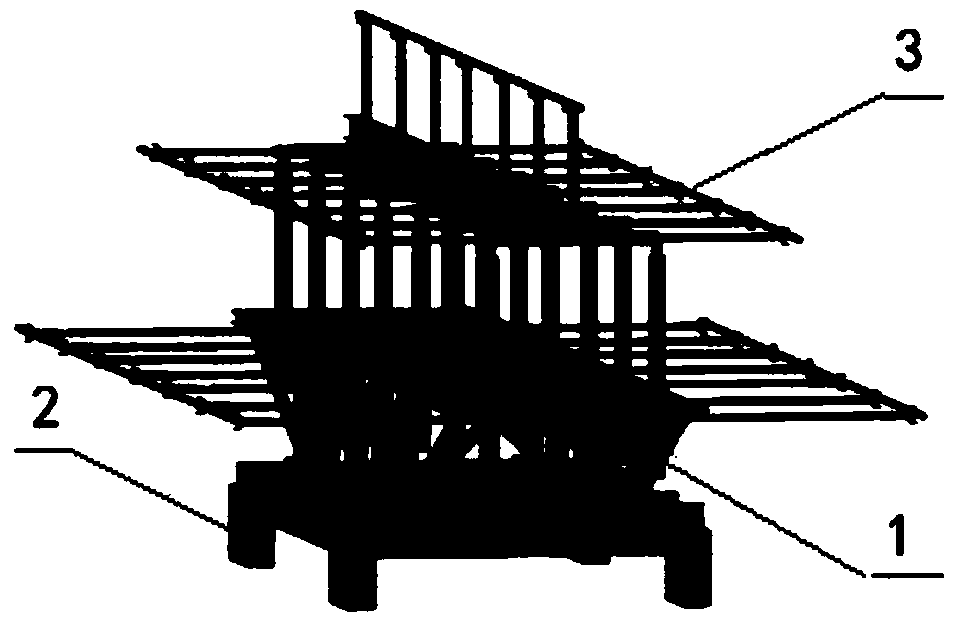

[0049] Such as Figure 1 to Figure 4 As shown, the mobile truss system is formed by connecting the truss module 1, the walking mechanism 2 and the reinforcing steel forming support module 3; the truss module 1 is composed of the upper truss and the lower truss supported by the column connection; the walking mechanism 2 is composed of a motor, a guide rail and The sliding wheel group is composed; the steel bar forming support module 3 is formed by the steel pipe group and the top bracket 4. The upper truss in the truss module 1 is formed by connecting 14 columns, 7 beams and 1 longitudinal beam. The lower truss is composed of 10 uprights, 22 diagonal tie rods, 14 beams, and 4 longitudinal beams.

[0050] Such as Figure 5 As shown, the upper truss in the truss module 1 is raised and lowered by setting the top span, and the top span is symmetrically welded and installed on the two uprights of the upper truss. After adjusting the top span in place, it is connected and fixed with a p...

specific Embodiment 2

[0068] Such as Image 6 , Figure 7 As shown, on the basis of embodiment 1, the steel pipe components in the steel bar forming support module 3 are horizontal horizontal steel pipes 5 and longitudinal horizontal steel pipes 6, the jack 4 is an adjustable jack 4, and the transverse horizontal steel pipe 5 is welded On the truss beam, five longitudinal horizontal steel pipes 6 are welded to the outside of the top bracket 4, and the supporting module is accurately positioned by the top bracket 4 screws on the top bracket 4.

[0069] The horizontal horizontal steel pipe 5 and the vertical horizontal steel pipe 6 are steel pipes with a telescopic structure, which are adjusted and locked by adjusting screws. The specific structure can refer to the prior art.

specific Embodiment 3

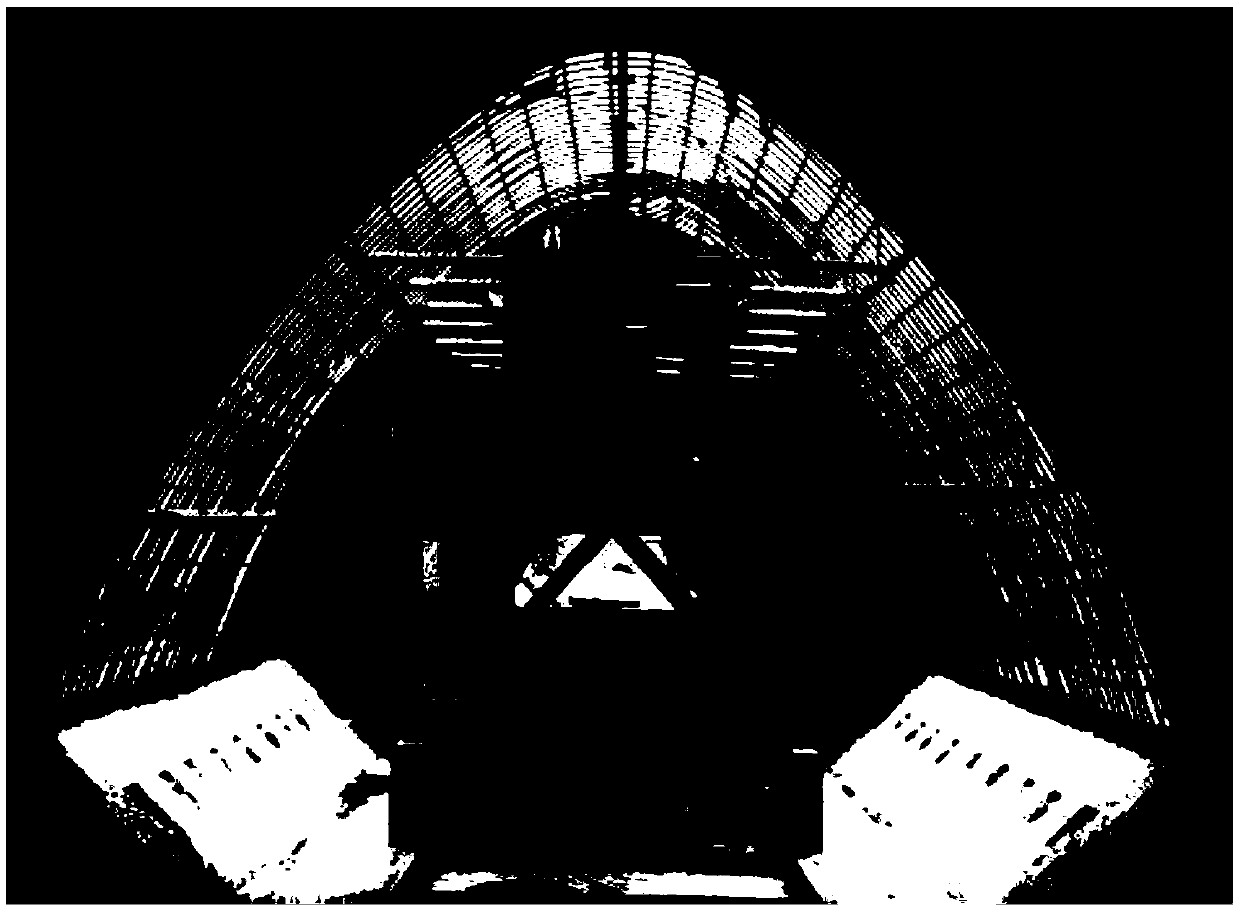

[0070] Such as Figure 8 As shown, on the basis of Embodiment 1, the sliding wheel set in the traveling mechanism 2 is 4 traveling wheels installed at the bottom of the mobile truss system, which are movably connected with the corresponding guide rails, and the motor provides power for the entire system.

[0071] When the device is used, the use method of the open-cut arch culvert is used to tie the steel bars of the arch body first and then support the arch formwork, which overturns the open-cut operation conditions and makes the operation more efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com