Simulation and control device for flue gas system

A control device and flue gas technology, which is applied to the simulation device of space navigation conditions, transportation and packaging, instruments, etc., can solve the problem that the system cannot be automatically put into operation, and achieve the effect of saving electric energy, reducing the consumption of consumables, and protecting the full load of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

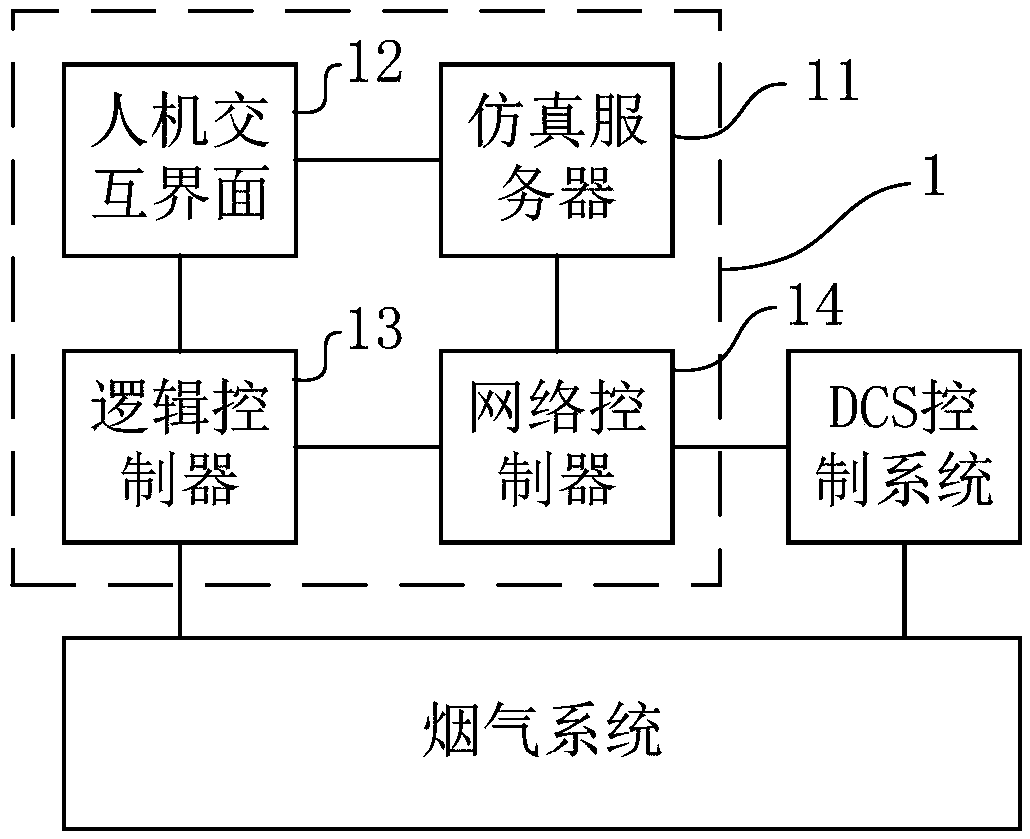

[0022] figure 1 It is a schematic diagram of the simulation and control device of the flue gas system of the present invention. like figure 1 As shown, the simulation and control device of the flue gas system of the present invention is marked as 1 in the figure, that is, the part in the virtual frame, which is independent of the flue gas system and belongs to a plug-in simulation and control device. The flue gas system includes a DCS system, namely "production process control system", which is used to collect real-time or historical data of the flue gas system operation process.

[0023] It should be noted that the flue gas system of the present invention can be a system of any structure related to flue gas emission, such as flue gas cooling, flue gas desulfurization and denitrification, flue gas purification, flue gas waste heat utilization and other systems or combinations thereof .

[0024] The flue gas system used in the present invention is usually controlled by a DCS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com