A Method for Improving the Modeling Accuracy of Precision Machine Tool Spatial Geometric Error Model

A technology of geometric error and model modeling, applied in geometric CAD, design optimization/simulation, etc., can solve the problems of large uncertainty in modeling accuracy and error analysis of CNC machine tools, modeling accuracy error, theoretical calculation error, etc. Good market application prospect and promotion value, the effect of achieving precision and eliminating theoretical calculation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

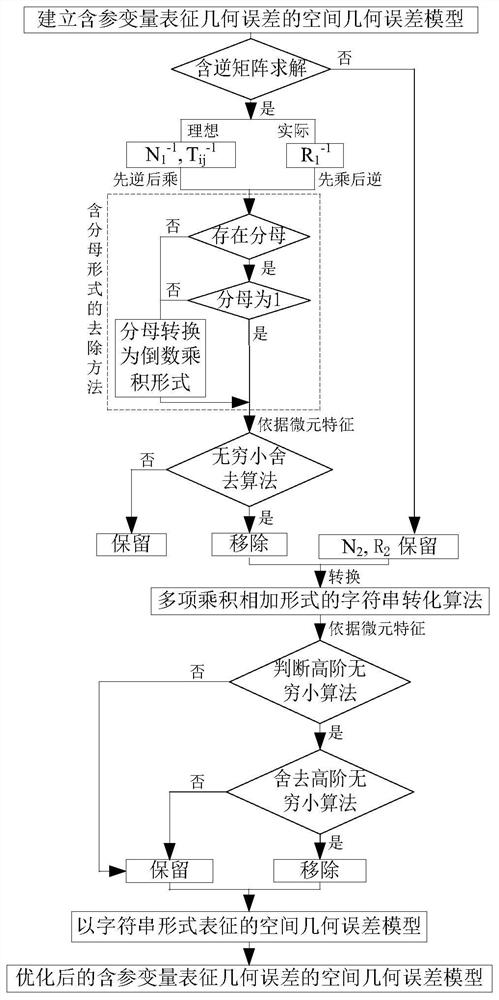

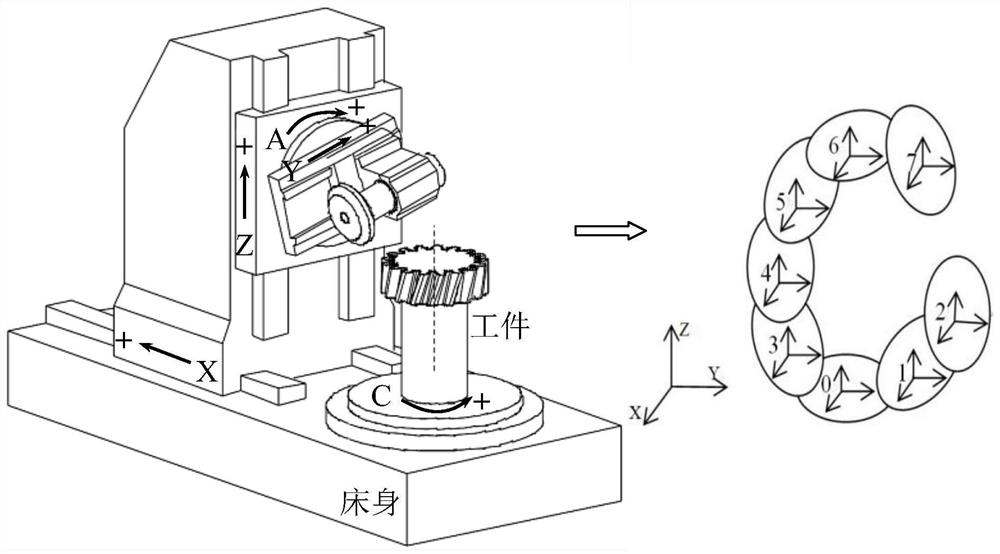

[0029] Now take the five-linkage CNC forming gear grinding machine SKMC-3000 / 20 as an example to illustrate the solid modeling object, such as figure 2 As shown, based on the multi-body system theory and the homogeneous coordinate transformation method, based on the theory of small error assumptions and ignoring high-order infinitesimals, aiming at the modeling accuracy of the spatial geometric error model with parameters representing the elements of the geometric error term, through the basis of mathematical theory and data processing analysis, a method for improving the modeling accuracy of precision machine tool space geometric error model is proposed.

[0030] For the convenience of the following expressions, the relevant definitions and relevant assumptions are now made:

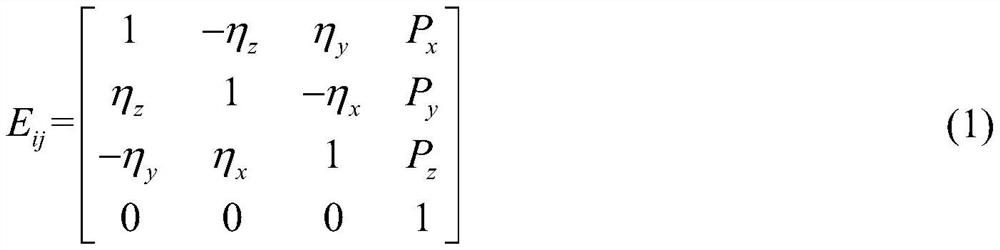

[0031] 1. According to the multi-body system theory and homogeneous coordinate transformation, the homogeneous coordinate transformation matrix ΔT 27 Equivalent to the homogeneous coordinate transform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com