A special test fixture for a vehicle camera

A technology for testing fixtures and cameras, which is applied in the fields of vehicles and machinery, can solve problems such as insufficient positioning accuracy, improper design of clamping mechanism, and lack of clamping force, etc., and achieve the effect of reliable pressing and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

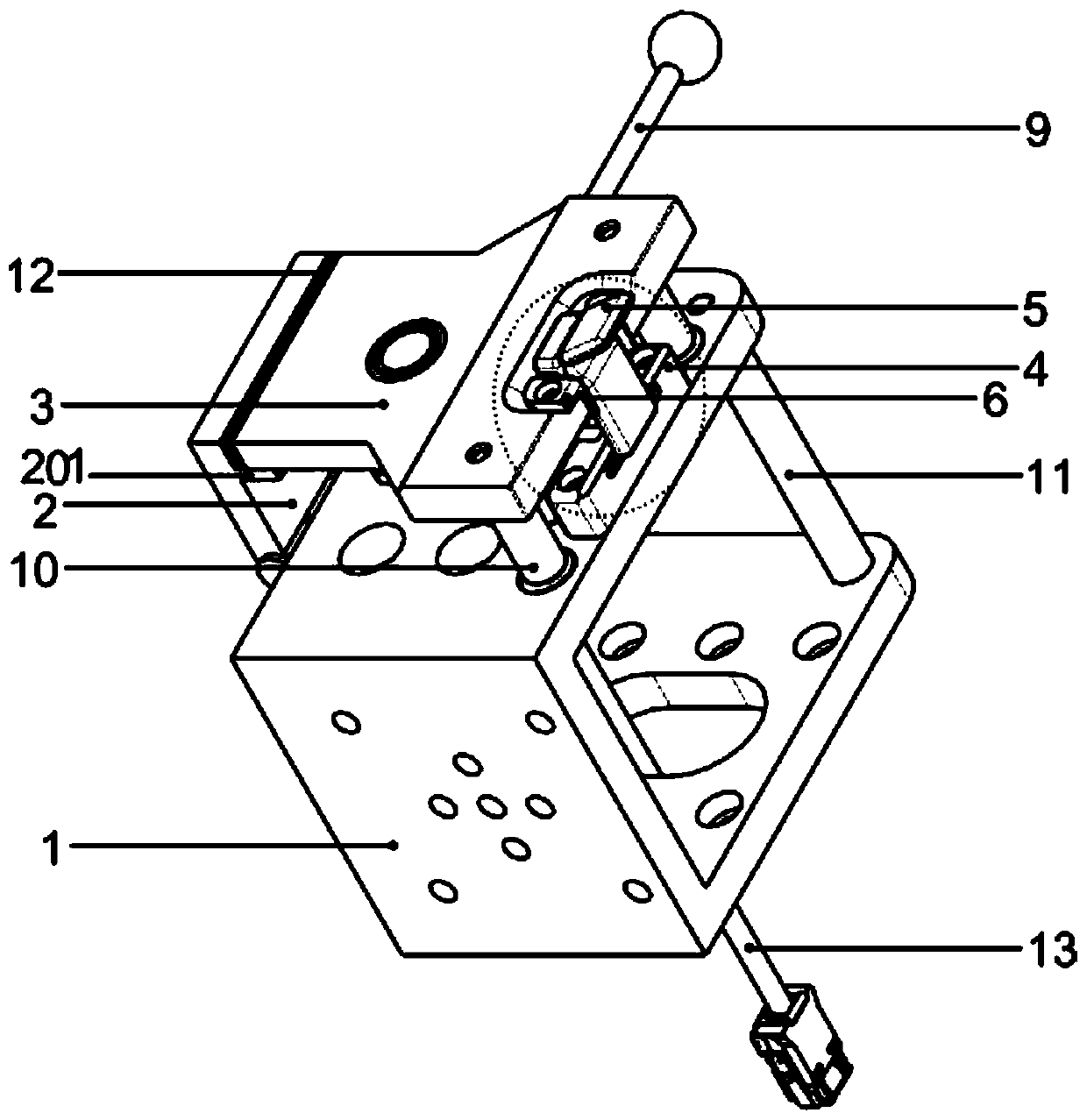

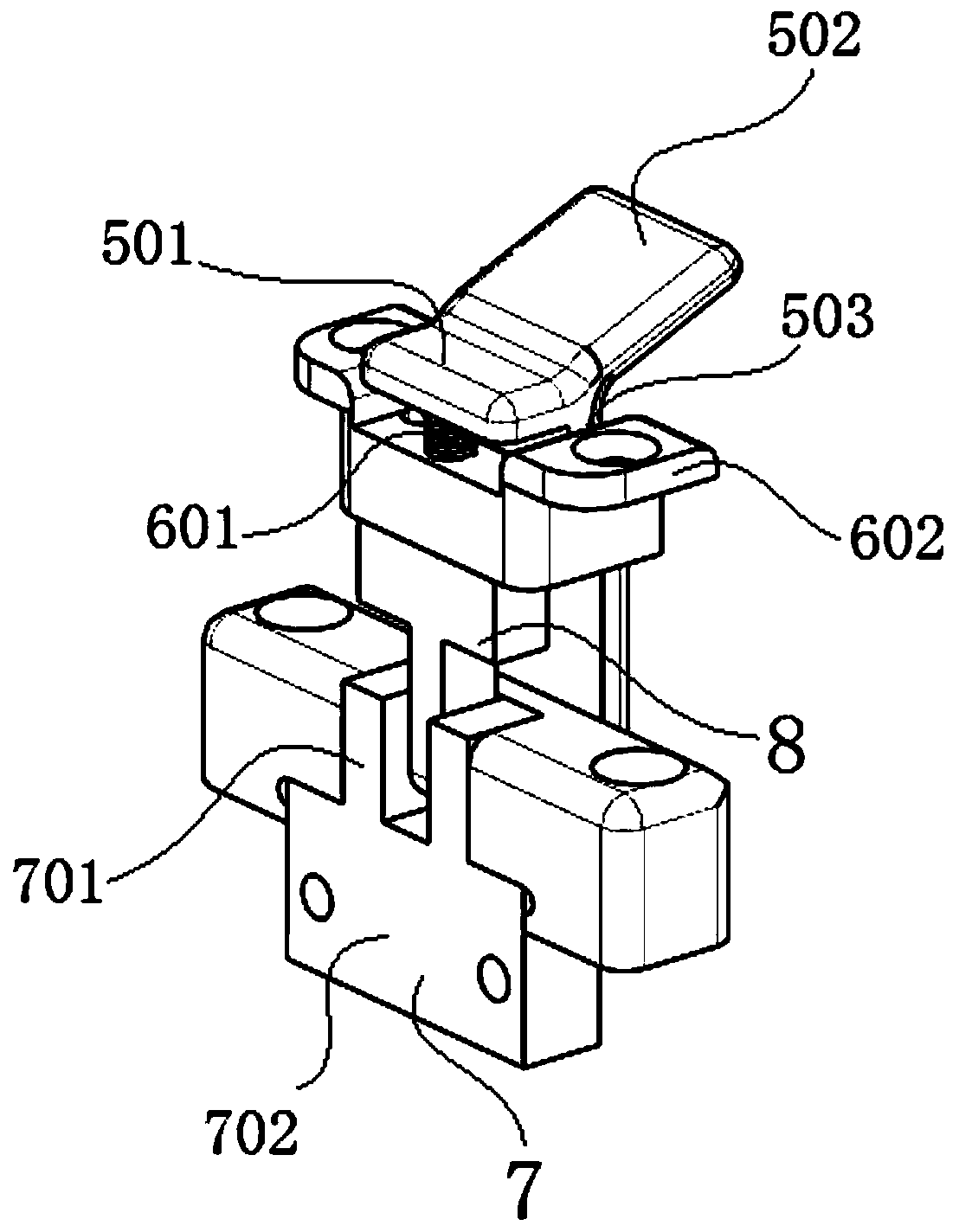

[0075] Such as Figure 1~7 As shown, a special test fixture for a vehicle camera is characterized in that it includes System I, System II, System III and System IV.

[0076] The system I includes a fixed bracket 1, a pressure plate limiting column 10, and a fixed bracket column 11.

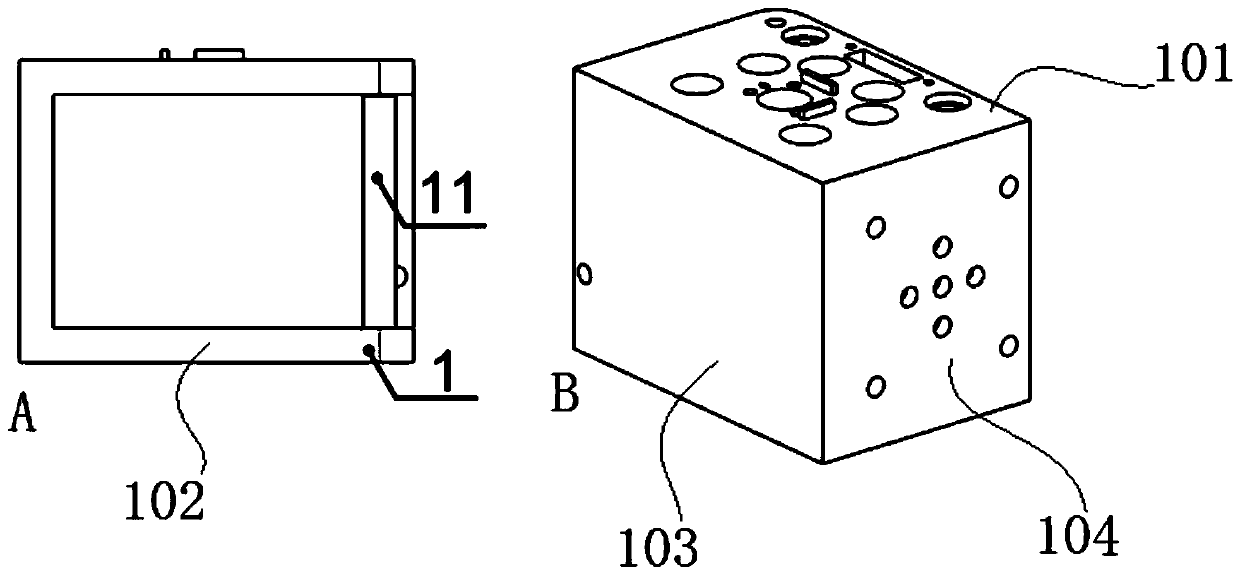

[0077] The fixing bracket 1 includes a top surface 101, a bottom surface 102, a first side surface 103 and a second side surface 104. The first side 103 and the second side 104 are connected. The overall structure of the fixing bracket 1 is semi-enclosed.

[0078] A fixed support pillar 11 is connected between the top surface 101 and the bottom surface 102 of the fixed support 1. The connecting side of the first side surface 103 and the second side surface 104 corresponds to the position of the fixed support pillar 11.

[0079] The fixed support pillar 11 increases the dynamic and static rigidity of the fixed support 1 and avoids the instability of the test results of the whole set of fixtures under vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com