Flying dust type adsorber

An adsorber and regulator technology, which is applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as discount of adsorption capacity, and achieve the effects of convenient operation, simple structure and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

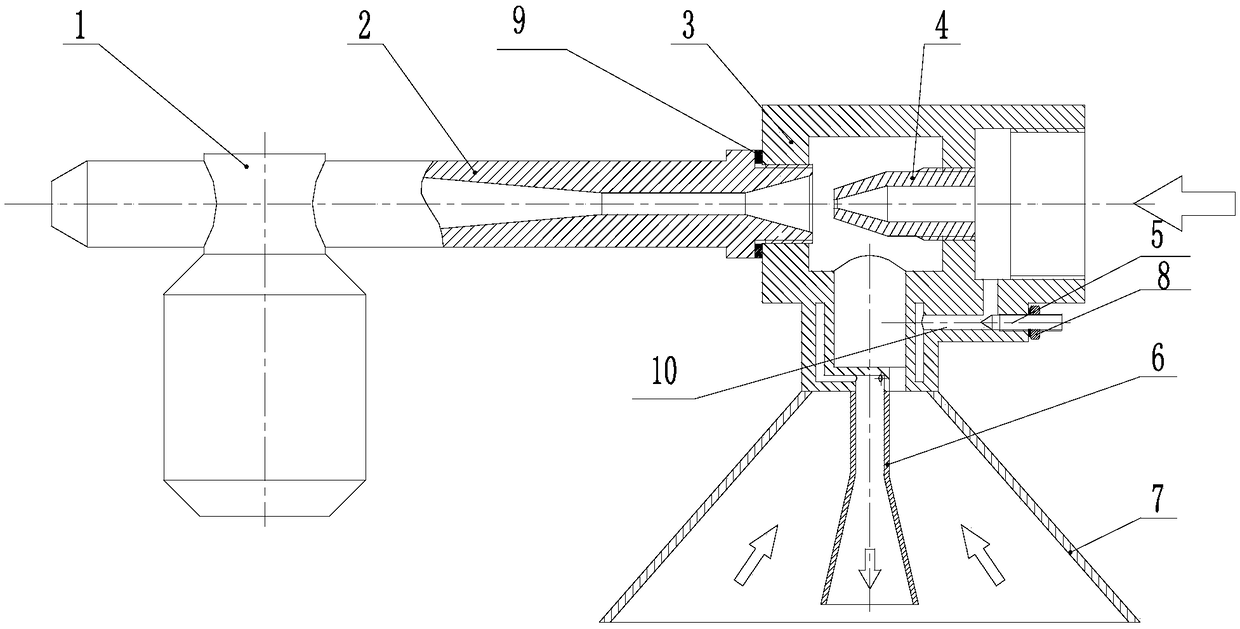

[0016] Dust-type adsorber, which includes a filter 1, a mixing tube 2, a jet chamber 3, a jet nozzle 4, a dust air regulator 5, a dust air launch tube 6 and an adsorption guide cover 7, and the mixing tube is connected to the jet through a thread At the air outlet of the jet chamber, the jet nozzle is embedded in the air inlet of the jet chamber and corresponds to the mixing tube. The jet chamber is also provided with a dust airflow adjustment hole 10, and the dust airflow regulator is installed in the dust airflow At the adjustment hole, the dust airflow launching tube is installed at the dust air inlet of the jet chamber and communicates with the jet chamber air inlet through the dust airflow adjustment hole, and the adsorption guide cover is placed outside the dust airflow launching tube and connected with The jet chamber communicates with the filter installed at the outlet end of the mixing tube.

[0017] Further, the adsorption shroud communicates with the jet chamber thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com