Efficient piston ring installing tool

A technology for installing tools and piston rings, applied in the field of high-efficiency piston ring installation tools, can solve problems such as adverse effects of rear ring assembly, excess piston ring design stress, cracks, etc., to improve assembly quality and operation efficiency, and to facilitate the assembly operation process. Fast, overcoming the effect of unfavorable factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

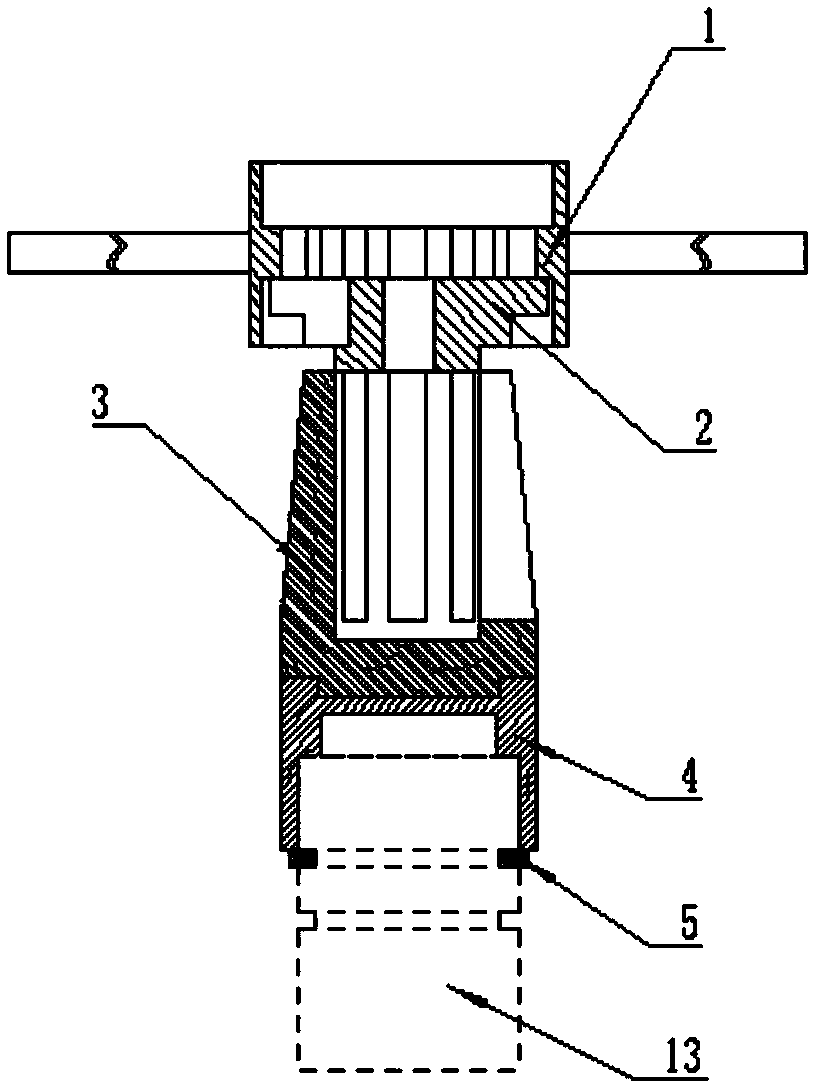

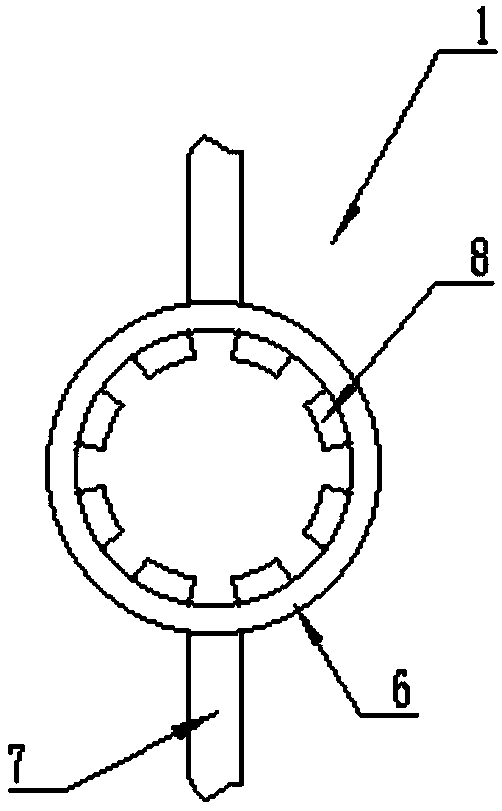

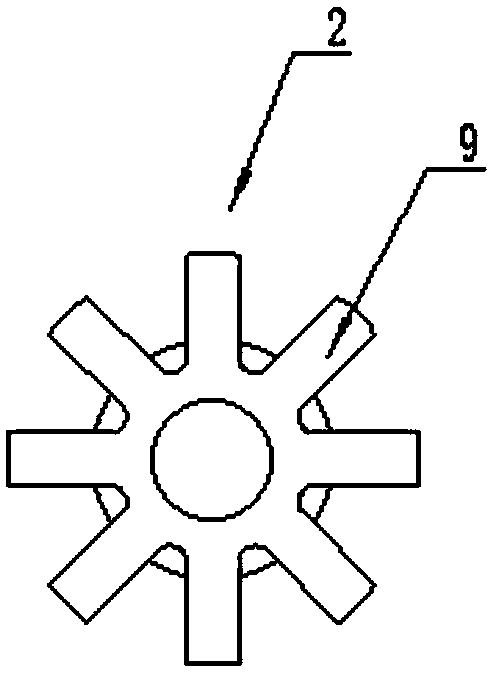

[0024] Such as figure 1 , a high-efficiency piston ring installation tool, which includes a push piece 1, a pressure block 2, an expansion sleeve 3, a bush 4 and a piston ring 5, the push piece 1 is composed of a cylindrical ring body 6 and a handle 7, and the A handle 7 is respectively fixed on both sides of the face annular body 6, and the axes of the two handles 7 are the same straight line, as figure 2 , image 3 with Figure 4 , a plurality of equidistant bosses 8 are arranged along the circumference of the inner wall middle of the cylindrical annular body 6; Plate 9; the outer wall of the expansion sleeve 3 is a tapered structure, the middle of the expansion sleeve 3 is provided with a cylindrical cavity 10, and a plurality of pressure supply blocks 2 are provided on the wall of the expansion sleeve 3 along the axial direction The sliding groove 11 that the rib plate 9 moves downward from one end of the expansion sleeve 3, such as Figure 5 The bushing 4 is a cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com