Prefabricated assembly-type ecological earth-retaining supporting structure

A prefabricated assembly and support structure technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of messy construction site, high engineering cost, low work efficiency, etc., and achieve the effect of convenient use, economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

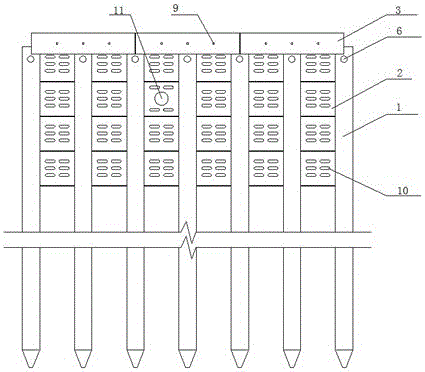

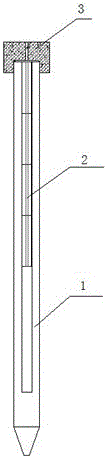

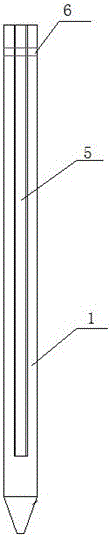

[0026] see Figure 1-Figure 6 As shown, the present invention provides a prefabricated assembled ecological soil retaining support structure, including a resistance column 1, a prefabricated ecological soil retaining insert 2 and a prefabricated crown beam 3, and the resistance column 1 is vertically set up according to a set distance, Prefabricated ecological soil retaining boards 2 are inserted horizontally between the resistance columns 1, and prefabricated crown beams 3 are installed on top of the resistance columns 1 and prefabricated ecological soil retaining boards 2 to form a column-slab-beam structural wall.

[0027] As a better embodiment, the prefabricated ecological soil retaining board 2 is provided with vertical hanging rib holes 4 inside. Inserting the hanging rib in the vertical hanging rib hole 4 can not only lift the hanging board, but also play the role ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com