Preparation method and application of anisotropic elastic auxetic fabric

An anisotropic fabric technology, which is applied in the preparation of anisotropic elastic auxetic fabrics and in the field of textile materials, can solve the problems of low production efficiency, cumbersome production, and difficult to meet, and achieve low cost, simple process, and simple production process easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

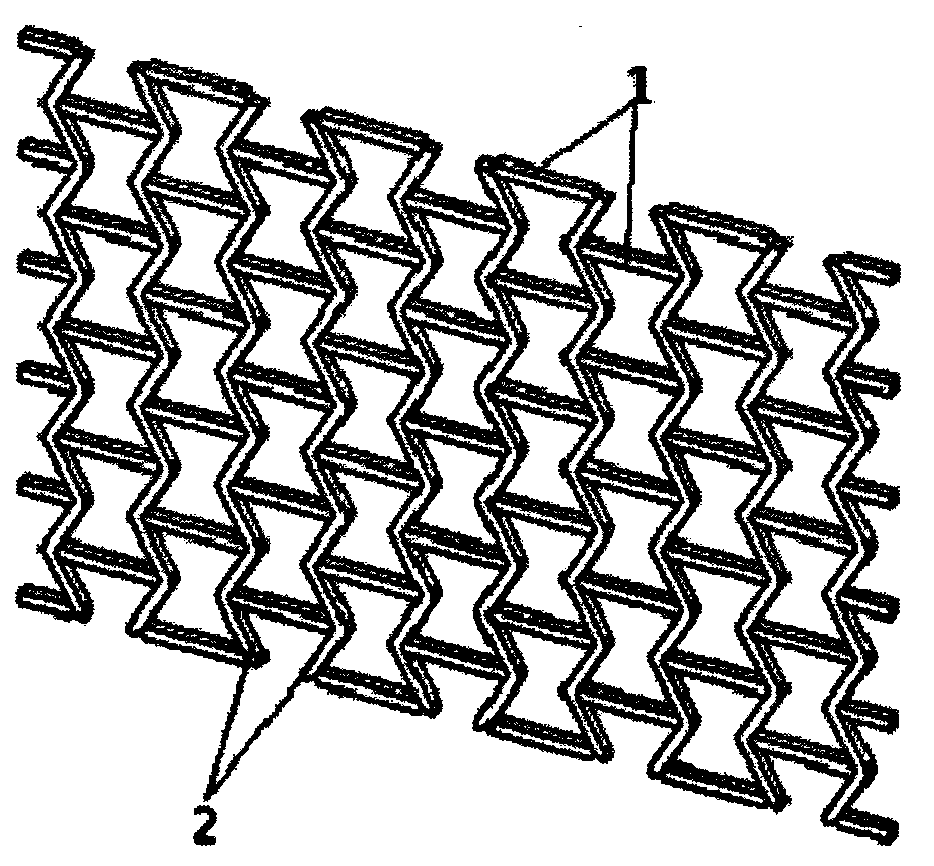

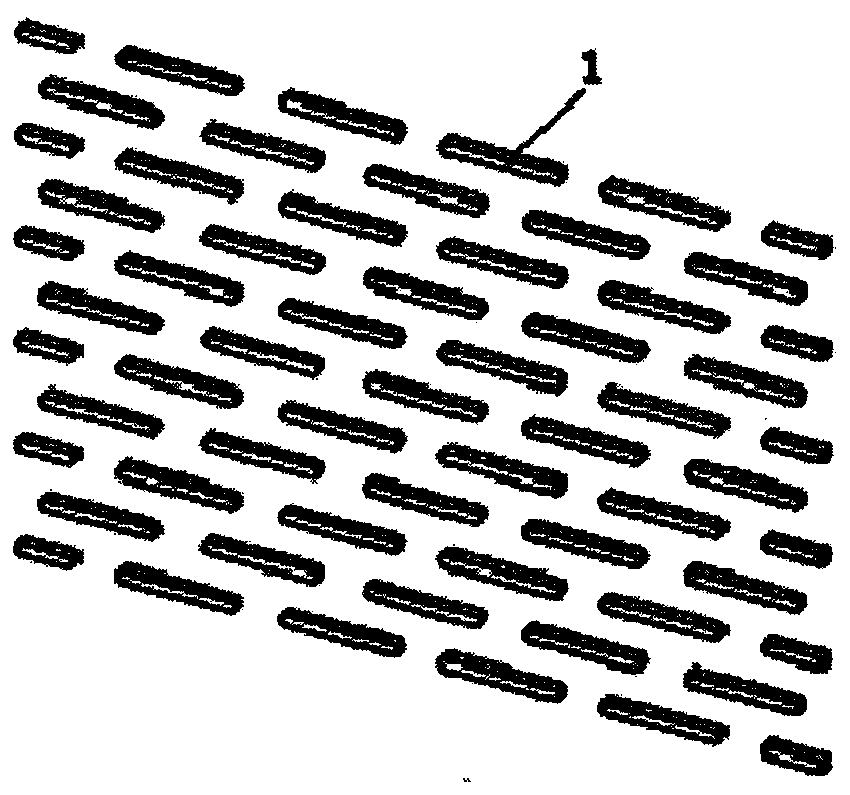

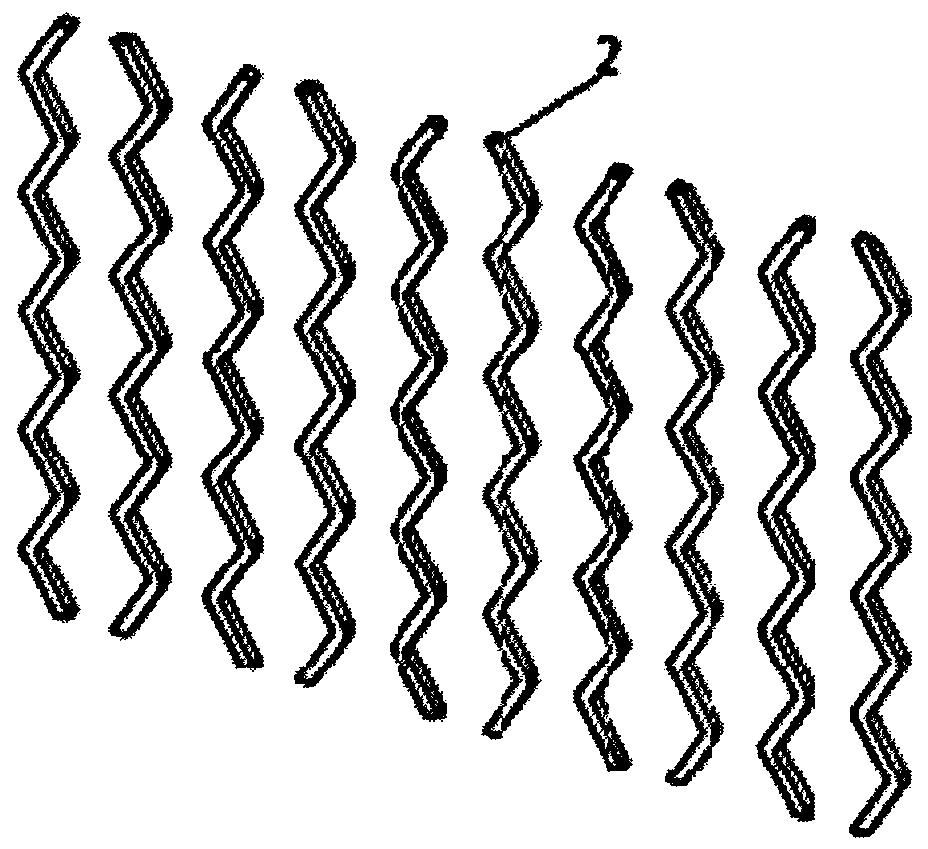

[0034] In order to achieve the above object, the preparation method of a kind of anisotropic elastic auxetic fabric provided by the present invention comprises the following steps:

[0035] Step 1. According to different requirements and uses, design the material, shape and size of the fabric so that the fabric has an auxetic structure;

[0036] Step 2. Modeling with 3D modeling software to construct corresponding 3D models of the two materials;

[0037] Step 3. Import the built 3D model into the software to assemble and make slices, and then import the slices into the 3D printer;

[0038] Step 4. Select the 3D printer material according to the design purpose to ensure that the elasticity of the horizontal material is greater than that of the vertical material;

[0039] Step 5. According to different design purposes, post-process the fabric printed by 3D printing technology to obtain the auxetic structure material.

[0040] Patterns of auxetic structures include concave honeyc...

Embodiment 5

[0052] Embodiment 5) Triangular sofa release.

[0053] Carry out corresponding parameter setting to the component parts involved in 5 embodiments, comprise (1) model parameter design, according to the quality of final product, thickness size requirement, design the size of model; (2) the selection of fiber, according to product quality and Performance requirements, choose two fibers with different elastic properties; (3) selection of 3D printing parameters, select the corresponding 3D printing technology and corresponding printing parameters according to the product use and raw materials; (4) post-processing design, according to the product use, Design fabric post-treatment process. The setting parameters of this embodiment are shown in Table 1.

[0054] Table 1

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com