Intelligent adjustable high-precision material discharging device used for full-automatic food packing machine

A technology of food packaging and blanking device, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of difficulty in accurate measurement, fast packaging, large error in bagging weight, and low bagging work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

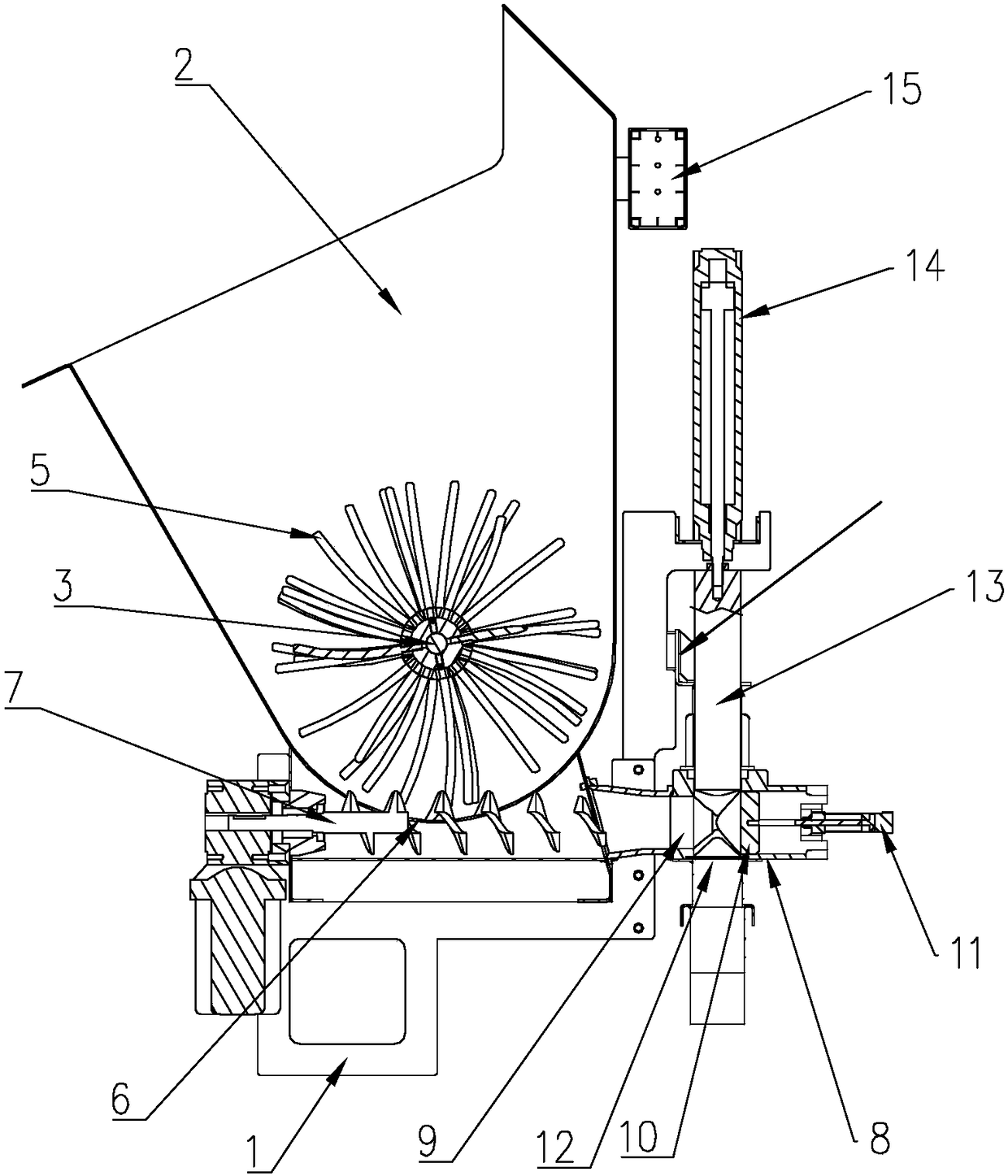

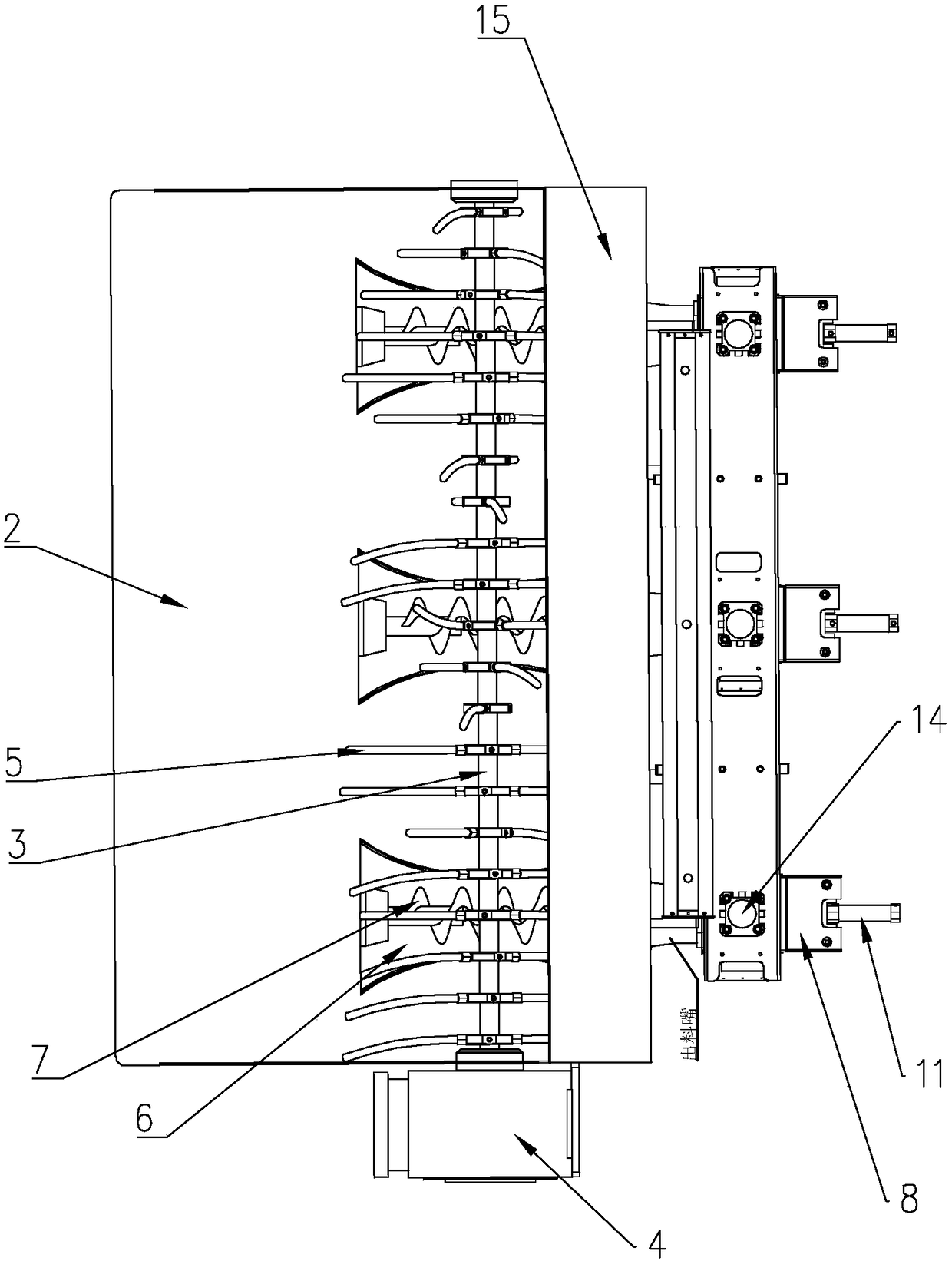

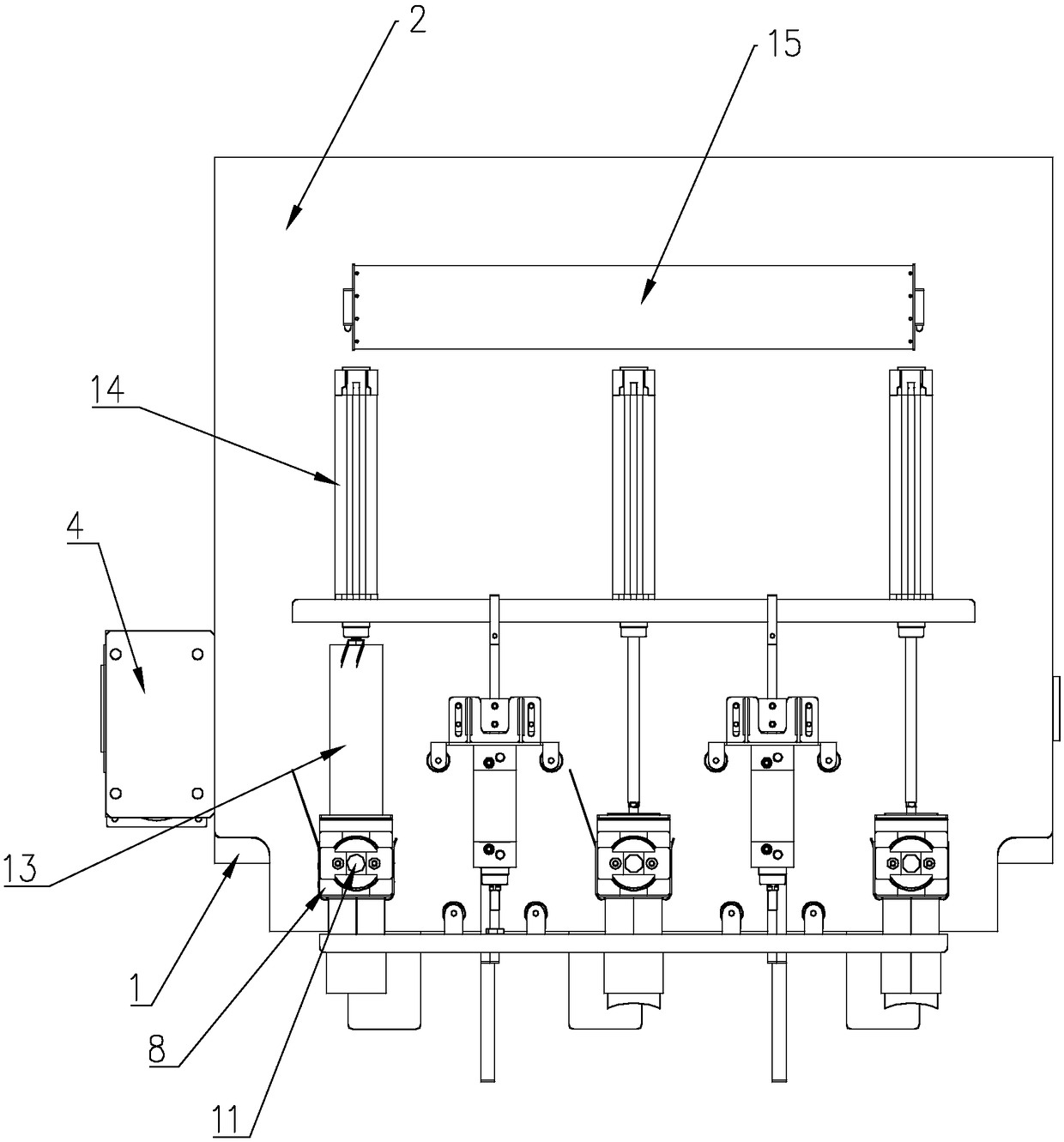

[0018] Such as figure 1 , figure 2 and image 3 As shown, the intelligent adjustable high-precision blanking device for a full-automatic food packaging machine of the present invention includes a machine base 1, on which a hopper 2 is arranged, the top of the hopper 2 is provided with a feeding port, and the middle part of the hopper 2 is arranged along the A stirring shaft 3 is provided in the front and rear horizontal directions, and the front and rear ends of the stirring shaft 3 are respectively installed on the side wall of the hopper 2 through a bearing seat. The outside is surrounded by a plurality of stirring rods 5, and the inner end of each stirring rod 5 is fixedly connected with the stirring shaft 3; when in use, the feed inlet at the top of the hopper 2 is used for feeding, and the stirring shaft drive motor 4 is used to allow the Stirring shaft 3 rotates, and stirring bar 5 is used for stirring the food that comes in.

[0019] The lower part of the hopper 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com