Outer rough surface uniform grinding mechanism for steel preparation

A grinding mechanism and rough surface technology, applied in machine tools suitable for grinding workpiece planes, parts of grinding machine tools, and grinding machines, etc., can solve problems such as uneven force on steel, large grinding force on steel, and pits on the outer surface. , to avoid grinding vibration, enhance blocking force, and prevent gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 1-Figure 5 Shown:

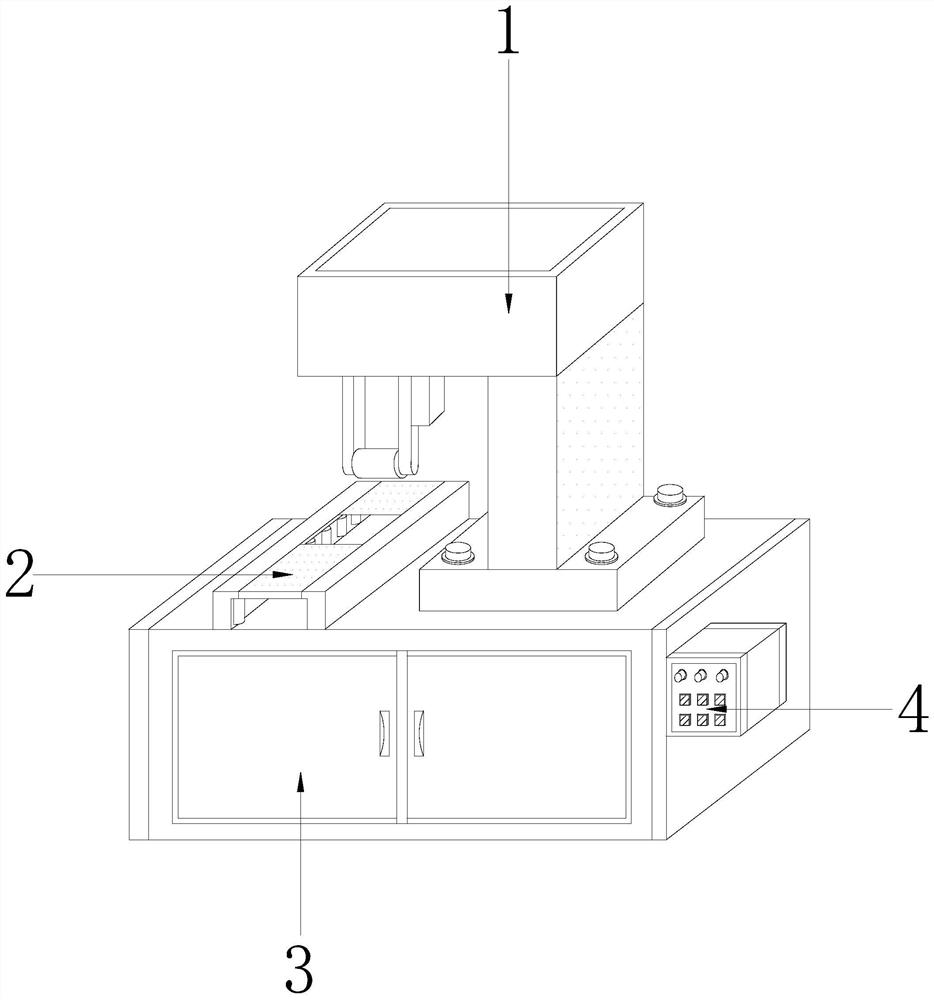

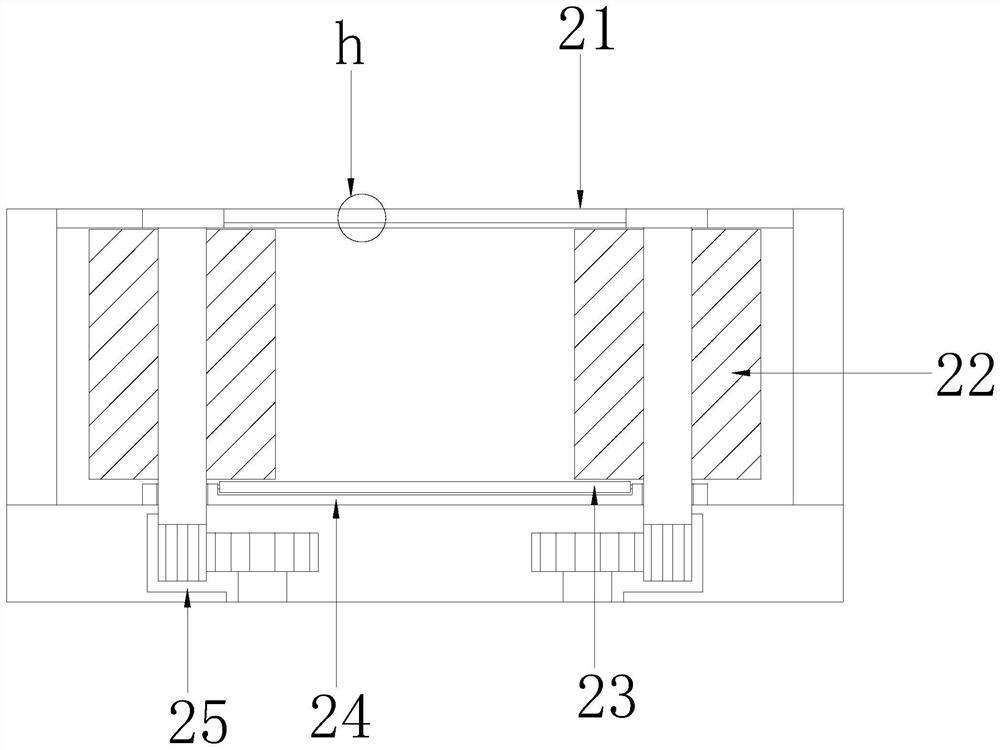

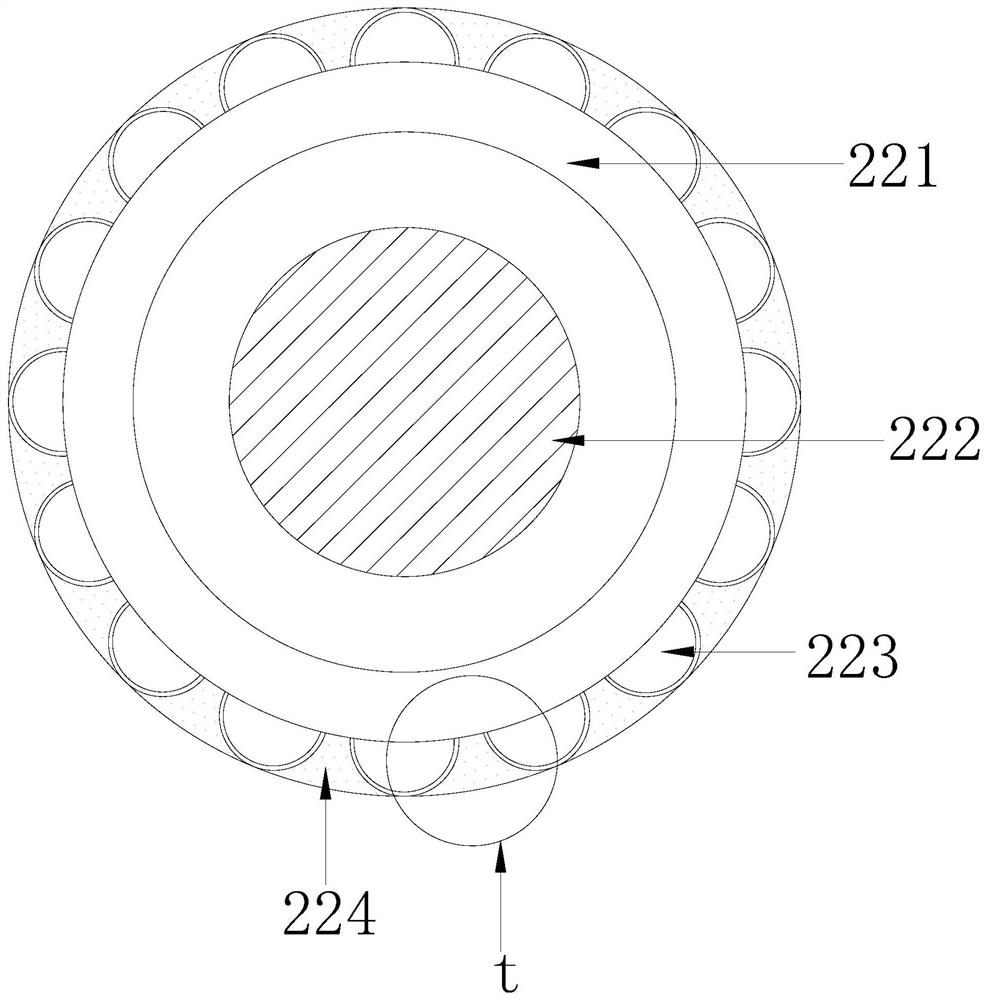

[0027] The present invention is a mechanism for uniformly polishing the surface rough surface for steel preparation, and its structure includes a polisher 1, a polishing fixture 2, a mechanical box 3, and a controller 4. The lower end of the polisher 1 is installed on the upper end of the mechanical box 3, and the control The device 4 is embedded and fixed on the right side of the mechanical box 3, and the lower end of the grinding and fixing device 2 is welded on the upper surface of the mechanical box 3. The grinding and fixing device 2 is provided with a blocking mechanism 21, a rotating mechanism 22, a drum 23, a fixing plate 24, parts Plate 25, the lower end of the blocking mechanism 21 is embedded in the middle of the upper ends of the two part plates 25, the inner lower end of the part plate 25 and the lower ends of the two rotating mechanisms 22 are mutually installed, and the left and right sides of the roller 23 are fixed in...

Embodiment 2

[0034] Such as Figure 6-Figure 8 Shown:

[0035] Wherein, the blocking mechanism 21 is provided with a blocking plate 211, a compression plate 212, and a sliding structure 213, the compression plate 212 is engaged inside the blocking plate 211, and the left and right sides of the sliding structure 213 are installed inside the side of the support plate 214, The support plate 214 is attached to the lower end of the blocking plate 211, and the blocking plate 211 is embedded in the middle of the upper end of the component plate 25. The compression plate 212 is made of rubber material and has a continuous bending structure. The lower end of the supporting plate 214 is a continuous The arc-shaped structure has the effect of less friction points, so that when the steel is polished, the upper surface of the steel slides with the sliding structure 213 on the side of the support plate 214, so that the steel exerts a force on the support plate 214 under the force of grinding and polishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com