Position and angle adjusting locating mechanism for drilling machine space of digging windlass and digging windlass

A technology of spatial position and angle adjustment, applied in drilling equipment, earthwork drilling, support devices, etc., can solve the problems of affecting work efficiency, poor swing effect of drilling rig, small swing radius, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

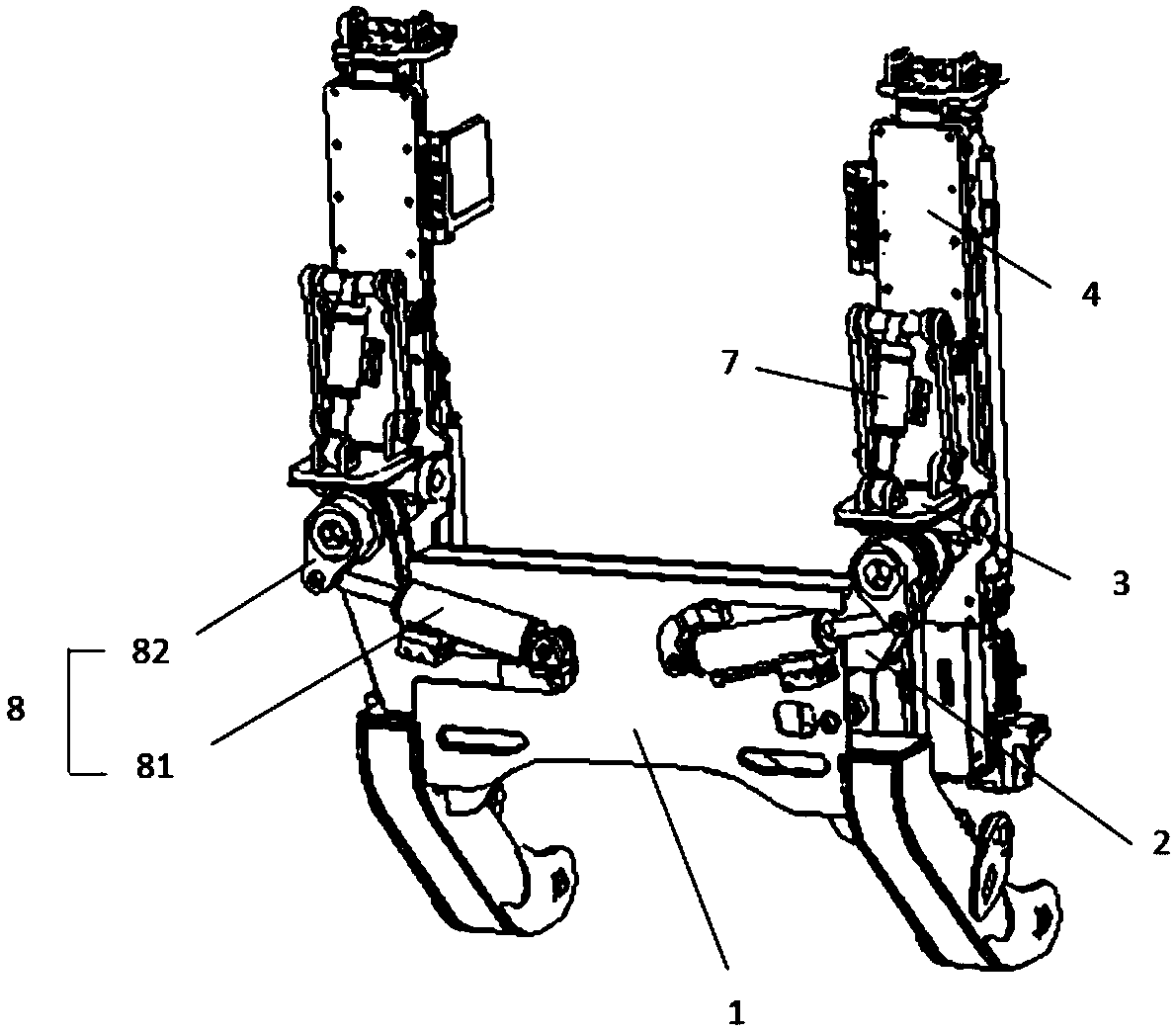

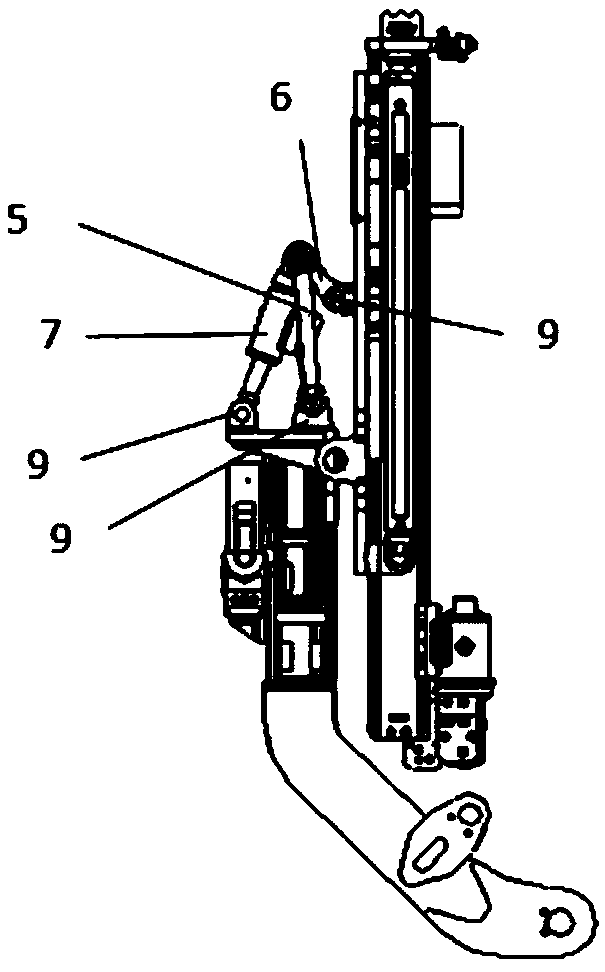

[0029] figure 1 It is a structural schematic diagram of the first viewing angle of the space position angle adjustment and positioning mechanism of the bolter drilling rig provided by Embodiment 1 of the present invention; figure 2 It is a structural schematic diagram of the second viewing angle of the space position angle adjustment and positioning mechanism of the bolter drilling rig provided by Embodiment 1 of the present invention; Figure 1-Figure 2 As shown, the bolter drilling rig spatial position angle adjustment and positioning mechanism provided by Embodiment 1 of the present invention includes a frame body 1, a telescopic beam 2, a turret 3, a drilling rig 4, a long swing rod 5, a short swing rod 6, and a swing drive device 7 and rotating device 8;

[0030] The telescopic beam 2 is installed in the frame body 1 and can move laterally in the frame body 1, the turret 3 is hinged on the telescopic beam 2, and the drilling machine 4 is installed on the turret 3 Above...

Embodiment 2

[0034] The space position and angle adjustment and positioning mechanism of the bolter drilling rig provided in the second embodiment is a further improvement on the space position and angle adjustment and positioning mechanism of the bolter drilling machine provided in the first embodiment. Figure 1-Figure 2 On the basis of the above, the space position angle adjustment and positioning mechanism of the bolter drilling rig provided in the second embodiment includes a frame body 1, a telescopic beam 2, a turret 3, a drilling rig 4, a long swing rod 5, a short swing rod 6, and a swing drive device 7 and rotating device 8;

[0035] The telescopic beam 2 is installed in the frame body 1 and can move laterally in the frame body 1, the turret 3 is hinged on the telescopic beam 2, and the drilling machine 4 is installed on the turret 3 Above, the long swing rod 5, the short swing rod 6, the drilling rig 4 and the turret 3 are hinged to each other to form a four-bar mechanism, one en...

Embodiment 3

[0042] The space position and angle adjustment and positioning mechanism of the bolter drilling rig provided in the third part of this embodiment is a further improvement on the space position and angle adjustment and positioning mechanism of the bolter drilling machine provided in the first embodiment. Figure 1-Figure 2 On the basis of the above, the space position and angle adjustment and positioning mechanism of the bolter drilling rig provided in the third embodiment includes a frame body 1, a telescopic beam 2, a turret 3, a drilling rig 4, a long swing rod 5, a short swing rod 6, and a swing drive device 7 and rotating device 8;

[0043]The telescopic beam 2 is installed in the frame body 1 and can move laterally in the frame body 1, the turret 3 is hinged on the telescopic beam 2, and the drilling machine 4 is installed on the turret 3 Above, the long swing rod 5, the short swing rod 6, the drilling rig 4 and the turret 3 are hinged to each other to form a four-bar mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com