Novel ultralow temperature stop valve and operation method thereof

A technology of ultra-low temperature and stop valves, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of reducing the life of the gasket, affecting the service cycle, and poor airtight stability, so as to improve the life of the gasket, increase the sealing performance, Life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

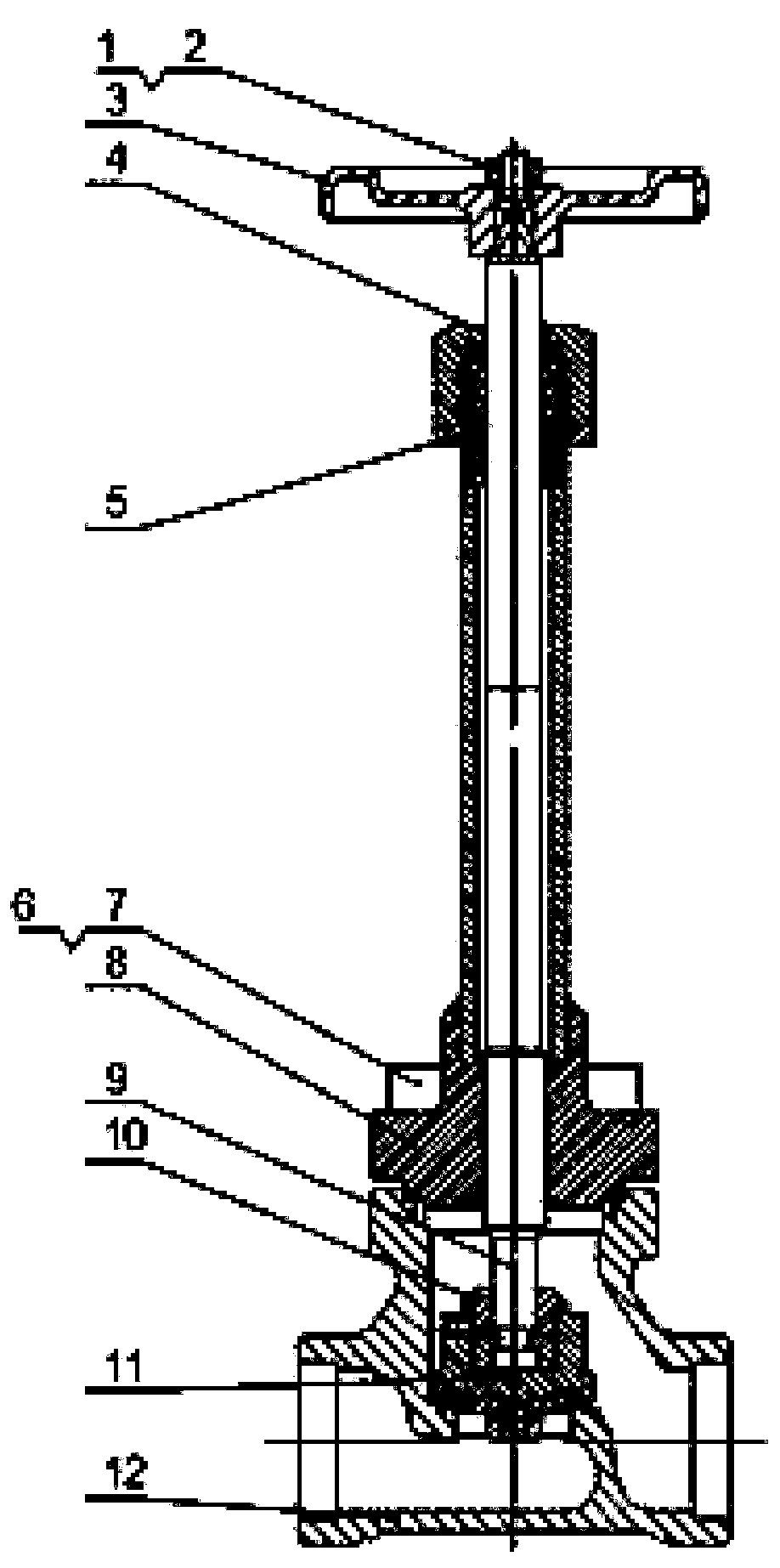

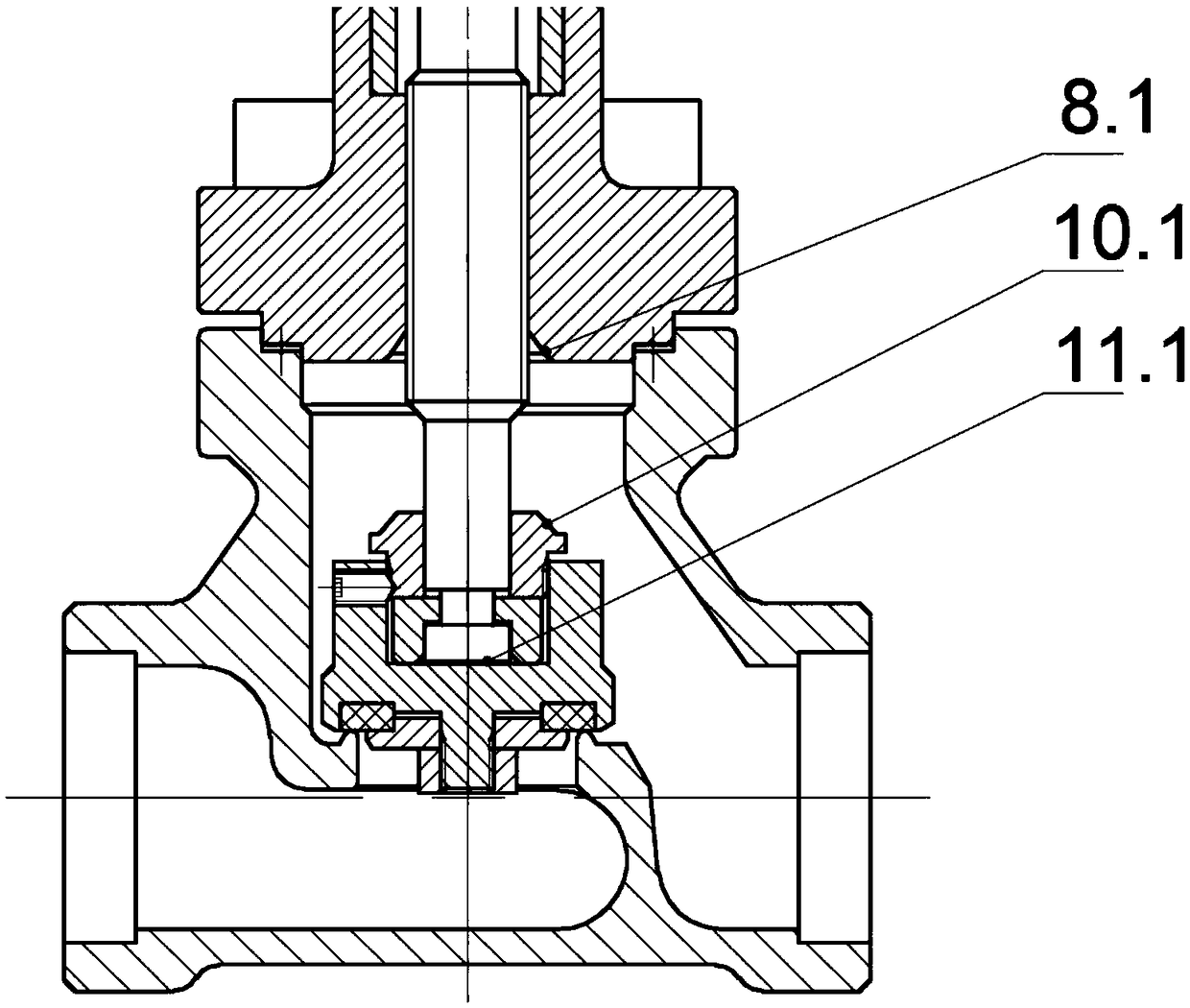

[0033] Such as figure 1 , figure 2 As shown, a novel ultra-low temperature shut-off valve includes: a valve body 12; a bonnet assembly 8 mounted on the valve body 12; a valve stem 9 screwed into the bonnet assembly 8 and connected to the bonnet assembly 8, the valve cover assembly 8 is provided with a valve cover cone 8.1 at the lower end of the threaded connection part of the valve stem 9; and a handwheel 3 is fixedly connected to the valve stem through the handwheel nut 1 and the elastic washer 9 on. When the hand wheel 3 is rotated counterclock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com